حقيبة معوجة عبارة عن مادة تغليف مرنة وظيفية يمكن أن تحافظ على الختم والاستقرار الهيكلي وسلامة المحتوى في ظروف درجات الحرارة العالية. تُستخدم على نطاق واسع في مجالات تغليف المواد الغذائية التي تتطلب تعقيمًا بدرجة حرارة عالية، مثل الأطعمة المطبوخة والتوابل والوجبات السريعة ومنتجات اللحوم. من أجل ضمان عدم تشوه المنتج أو تسربه أو تلوثه أثناء المعالجة بدرجة حرارة عالية، فإن الحقيبة المعقمة لها متطلبات صارمة بشأن اختيار المواد والتصميم الهيكلي.

الحقيبة المعقمة: التغليف المثالي لإطالة العمر الافتراضي للأغذية

في إنتاج الأغذية ومعالجتها، هناك دائمًا عمليتان للطهي، وهما التعقيم بدرجة حرارة عالية وضغط مرتفع والتعقيم بدرجة حرارة منخفضة وضغط عادي. وتتمتع منتجات اللحوم المعقمة في درجة حرارة منخفضة بمذاق طازج ويتم الحفاظ على العناصر الغذائية المختلفة بشكل جيد لأن درجة حرارة التسخين منخفضة ولا يتم تدمير ألياف اللحوم.

ومع ذلك، نظرًا لأنه يقتل فقط البكتيريا المسببة للأمراض، لا يزال هناك عدد كبير من البكتيريا الفاسدة، والتي لا تتمتع بفترة صلاحية قصيرة فحسب، بل تتسبب أيضًا في خسائر في مجال التداول بسهولة. تحتوي منتجات اللحوم المعقمة بدرجة حرارة عالية على تقلص مفرط في ألياف اللحوم بسبب ارتفاع درجة حرارة التسخين العالية، كما أن الطعم ليس جيدًا مثل المنتجات المعقمة بدرجة حرارة منخفضة، ولكن نظرًا لأنه يقتل جميع البكتيريا ويقضي على الأسباب الداخلية للفساد، يمكن إطالة مدة الصلاحية بشكل كبير.

إذا كانت منتجات اللحوم المعقمة ذات درجة الحرارة العالية معبأة بمواد عالية الحاجز، فلن يكون لها عمر تخزيني طويل في درجة حرارة الغرفة فحسب، بل ستكون أيضًا ملائمة للنقل والتخزين والبيع، وهو أمر مناسب جدًا لاحتياجات الاستهلاك في المجتمع الحديث.

ولذلك، يعد التطوير القوي لإنتاج منتجات اللحوم التي يمكن تخزينها في درجة حرارة الغرفة اتجاهًا مهمًا لتطوير المنتجات لصناعة أغذية اللحوم. تتوافق صناعة التعبئة والتغليف مع هذا الاتجاه التنموي وتحقق بعض الإنجازات والابتكارات التي لا تلبي احتياجات صناعة الأغذية فحسب، بل تكسب سوقًا واسعًا لنفسها أيضًا.

بعد سنوات من الاستخدام، ثبت أن الحقيبة المعوجة ذات درجة الحرارة العالية هي حاوية تغليف مثالية للبيع. فهي تتمتع بمزايا كل من العبوات المعلبة والأكياس البلاستيكية المقاومة للماء المغلي. يمكن الاحتفاظ بالطعام سليمًا في الكيس ويمكن إخراجه وتناوله بعد تعقيمه وتسخينه في درجة حرارة عالية (بشكل عام 120 ~ 135 درجة مئوية). إنه مناسب لتغليف اللحوم ومنتجات الصويا. إنه مريح وصحي وعملي، ويمكنه الحفاظ على النكهة الأصلية للطعام، وهو أكثر شعبية لدى المستهلكين.

الغرض من تعقيم الحقيبة المعقمة وتصنيفها

الغرض من التعقيم

للقضاء التام على البكتيريا الضارة وتلبية متطلبات التعقيم، مثل تعقيم المستلزمات الطبية.

بعد التعقيم الشامل، يمكن أن يمنع نمو البكتيريا مع القليل من المواد الحافظة أو بدون مواد حافظة، ويطيل العمر الافتراضي للمحتويات، ويحافظ على النكهة الأصلية للمحتويات لفترة طويلة في درجة حرارة الغرفة، مثل مختلف المنتجات الغذائية المطبوخة على البخار في درجات حرارة عالية.

تصنيف طرق التعقيم

فيما يلي تصنيف أكياس التعبئة والتغليف ذات درجة الحرارة العالية التعقيم وفقًا للتصنيف الحالي المعترف به دوليًا:

- كيس معوجة يمكن أن يتحمل 121 درجة مئوية، مع زمن مقاومة لدرجات الحرارة العالية يتراوح بين 30-60 دقيقة.

- كيس معوجة يمكن أن يتحمل 135 درجة مئوية، مع زمن مقاومة للحرارة يتراوح بين 15 و30 دقيقة.

- كيس معقّم بدرجة حرارة عالية جدًا يمكنه تحمل 145 درجة مئوية، وهو أعلى مستوى من الأكياس المعقّمة حاليًا، مع زمن مقاومة للحرارة أقل من 5 دقائق.

يشيع استخدام الحقيبة المعوجة التي يمكنها تحمل 121 ℃ في السوق. بشكل عام، يجب أيضًا أن تفي المواد الصلبة مثل عبوات طهي اللحوم ذات درجة الحرارة العالية بمتطلبات التفريغ.

متطلبات الأداء لركائز أغشية الأكياس المعوجة

تعتبر الركيزة الغشائية المستخدمة في إنتاج الأكياس المعوجة ذات درجة الحرارة العالية هي الأساس لاستيفاء شروط الطهي. وعادةً ما يتم تحديد الركائز والمواصفات وترتيب التركيبات وأنواع الأحبار والغراء التي سيتم استخدامها وفقًا لظروف الطهي وخصائص محتويات الكيس المعاد معالج بدرجة حرارة عالية.

تشمل ركائز الأغشية الشائعة الاستخدام ما يلي: BOPET، BOPA، BOPA، HDPE، RCPP، RCPP، AL، EVOH، EVOH المبثوق المشترك، PVDC المبثوق المشترك، PE المبثوق المشترك، إلخ. في الوقت الحاضر، هناك أيضًا أفلام جديدة مقذوفة بشكل مشترك مع أكثر من خمس طبقات، مثل: PP/AC/AC/EVOH/AC/AC/PP، PP/AC/PA/PA/EVOH/PA/AC/PP، إلخ. وبالإضافة إلى ذلك، هناك النايلون البوليمر المشترك MXD6 والأفلام الخزفية المترسبة بالبخار مثل Si0xPET12um. ونظرًا لقيود العمليات التقنية وعوامل السعر، لا يتم استخدام الأغشية متعددة الطبقات المبثوقة المشتركة والأغشية السيراميكية المترسبة بالبخار في كثير من الأحيان في الأكياس المعوجة ذات درجة الحرارة العالية.

وفقًا لترتيب الطبقة السطحية (أو طبقة الطباعة) وطبقة الحاجز وطبقة الختم الحراري، يمكن دمج هيكل مواد التغليف المركبة. هناك أيضًا مواد أحادية الطبقة يمكن استخدامها كطبقة طباعة وطبقة حاجزة على حد سواء، لذلك يمكن تصميم كيس التغليف على شكل طبقتين أو ثلاث أو أربع طبقات أو أكثر وفقًا للاحتياجات، مثل: BOPET/RCPP، BOPA/RCPP، BOPET/BOPA/RCPP، BOPET/BOPA/RCPP، BOPET/AL/RCPP، BOPE-T/AL/BOPA/RCPP، إلخ.

بالنسبة لسمك الركيزة، يتم اختيارها عادةً على النحو التالي: BOPET12um، BOPA15um، BOPA15um، AL7um أو AL9um، RCPP50um، RCPP70um، RCPP80um، RCPP100um، إلخ. بالنسبة للطبقة الحاجزة، عادةً ما يتم اختيار BOPA و AL. وفقًا للاحتياجات الفعلية، يتم أيضًا اختيار BOPA25um و AL12um. كما أن سمك RCPP المختار للحقيبة المعوجة ذات درجة الحرارة العالية ذات السعة الكبيرة والمتطلبات الخاصة يزيد أيضًا عن 100 ميكرومتر. من أجل التغلب على عيب عدم مقاومة RCPP للسقوط، تضيف أكياس التعبئة السائلة عمومًا إضافات إلى الفيلم لتعزيز أدائها المضاد للسقوط.

متطلبات الغراء والحبر

تشير المواد الكيميائية المختارة لمواد تغليف الطهي ذات درجة الحرارة العالية بشكل أساسي إلى الأحبار والمواد اللاصقة والمذيبات.

الحبر

لا تقاوم الأحبار العادية درجات الحرارة العالية. سوف تنفصل بعد الطهي وتتغير بعض الألوان. يجب أن تكون أحبار الطهي ذات درجات الحرارة العالية أحبارًا ذات مكونين من البولي يوريثان التفاعلي كرابط. فهي تتمتع بالالتصاق الجيد في الطباعة ويمكنها تحمل الطهي في درجات حرارة عالية بعد تفاعل الربط المتقاطع والمعالجة. يمكن أن تشكل رابطة قوية للغاية مع الغراء.

في الوقت نفسه، بالنسبة للألوان الموضعية ذات المساحات الكبيرة والنقوش البيضاء، يجب أيضًا اختيار عوامل معالجة الحبر المطابقة. عند اختيار الأحبار، يجب إيلاء اهتمام خاص للتمييز بين الأحبار العادية والأحبار التي يمكن أن تتحمل الغليان أقل من 100 درجة مئوية والأحبار التي يمكن أن تتحمل الطهي بدرجة حرارة عالية فوق 121 درجة مئوية لتجنب سوء الاستخدام.

الصمغ

يجب أن يكون الصمغ من درجة مقاومة الطهي بدرجة حرارة عالية، والتي تعتبر بشكل عام لتلبية متطلبات التبخير فوق 121 ℃. بعد التركيب، يجب أن يتمتع بقوة ترابط جيدة ومقاومة درجات الحرارة العالية ومقاومة الحرارة. حاليًا ، الأكثر استخدامًا هو غراء البولي يوريثين المكون من عنصرين.

المذيبات

يجب أن يكون المذيب متطابقًا جيدًا مع الحبر والغراء، ويمكن أن يلبي متطلبات العملية، ولكن يجب ألا يؤثر على مقاومة الطهي في درجات الحرارة العالية للحبر والغراء.

التحليل الهيكلي للحقيبة المعوجة

استنادًا إلى الأداء الاقتصادي والخصائص الفيزيائية والكيميائية للمادة، تعتمد الحقيبة المعوجة شائعة الاستخدام بشكل أساسي على الهيكل التالي:

هيكل من طبقتين

- PET/CPP

- BOPA/CPP

- GL-PET/CPP

هيكل ثلاثي الطبقات

- PET/AL/CPP

- BOPA/AL/CPP

- PET/BOPA/CPP

- GL-pet/bopa/cpp

- PET/PVDC/CPP

- PET/EVOH/CPP

- BOPA/EVOH/CPP

هيكل رباعي الطبقات

- PET/PA/AL/CPP

- PET/AL/AL/PA/CPP

هيكل متعدد الطبقات

- فيلم PET/EVOH مقذوف مشترك/فيلم PET/EVOH/فيلم PET

- فيلم PET/PVDC مقذوف مشترك/فيلم PET/PVDC مقذوف مشترك/فيلم PET/PVDC

- رقائق PA/PVDC مقذوف مشترك/فيلم مقذوف مشترك/فيلم PVDC

- فيلم PET/EVOH مقذوف بشكل مشترك

- رقائق PA/PVDC مقذوفة بشكل مشترك

الخصائص الإنشائية للحقيبة المعوجة

يتكون الهيكل الأساسي للحقيبة المعوجة من طبقة سطحية/طبقة وسطى/طبقة مانعة للتسخين. مواد الطبقة السطحية هي عمومًا PET وBOPA، والتي تلعب دور دعم القوة ومقاومة الحرارة وقابلية الطباعة الجيدة. تستخدم الطبقة الوسطى مواد AL وPVDC وEVOH وBOPA، والتي تلعب بشكل أساسي دور الحاجز والوقاية من الضوء والمركب على الوجهين. تستخدم طبقة الختم الحراري أنواعًا مختلفة من CPP، وPP المقذوف المشترك وPVDC، والأفلام المقذوفة المشتركة EVOH. يستخدم فيلم LLDPE أيضًا للطبخ تحت 110 ℃، والذي يلعب بشكل أساسي دور الختم الحراري ومقاومة الثقب والمقاومة الكيميائية. يجب أن يكون للمادة أيضًا امتصاص منخفض ونظافة جيدة.

الملخص

بصفتها كيسًا خاصًا لتغليف المواد الغذائية، يجب ألا تتطلب الحقيبة المعوجة مقاومة جيدة لدرجات الحرارة العالية وخصائص الحاجز فحسب، بل يجب أن تلبي أيضًا السلامة وحماية البيئة. من خلال الاختيار الصحيح للمواد والتصميم الهيكلي الصحيح، يمكن أن يضمن حفظ الطعام في أفضل حالة أثناء الطهي والتخزين والنقل.

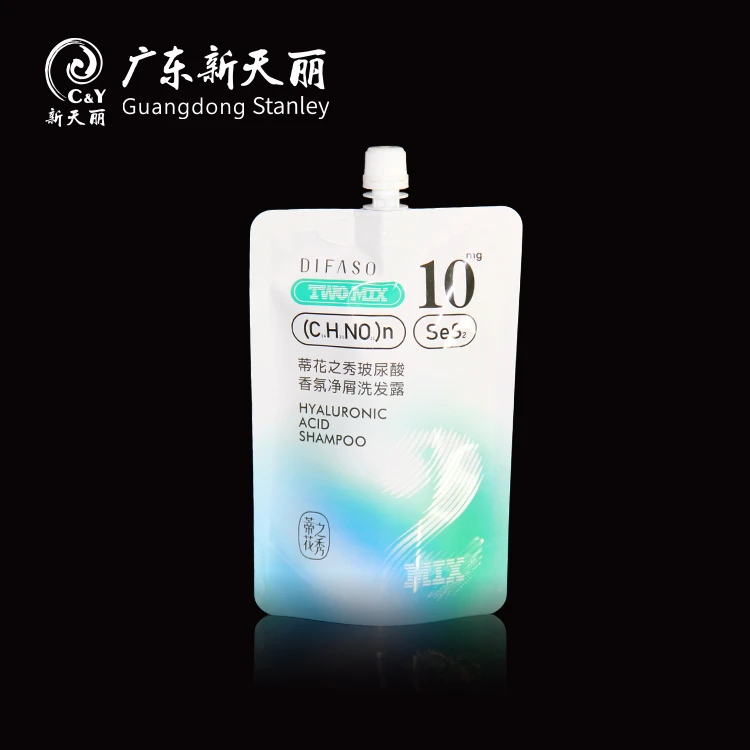

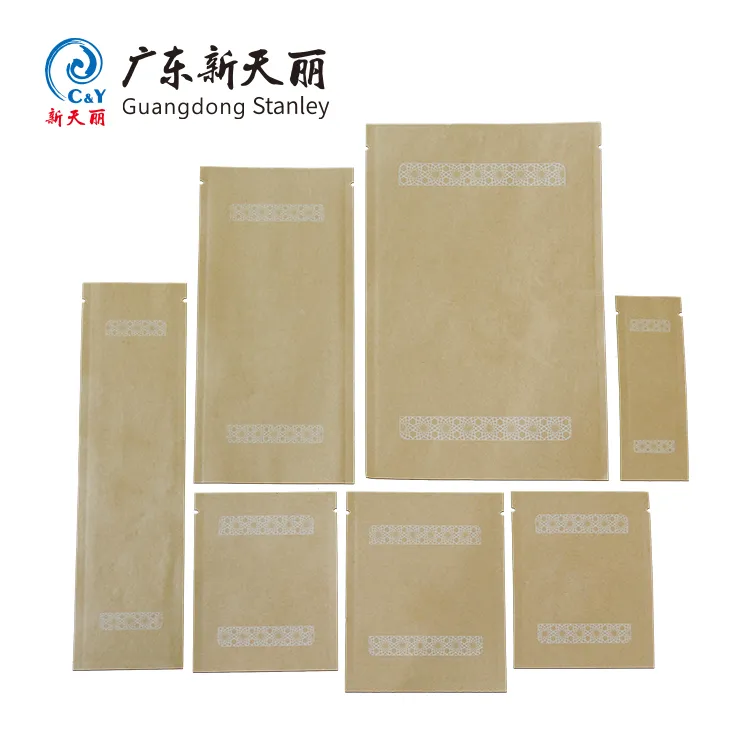

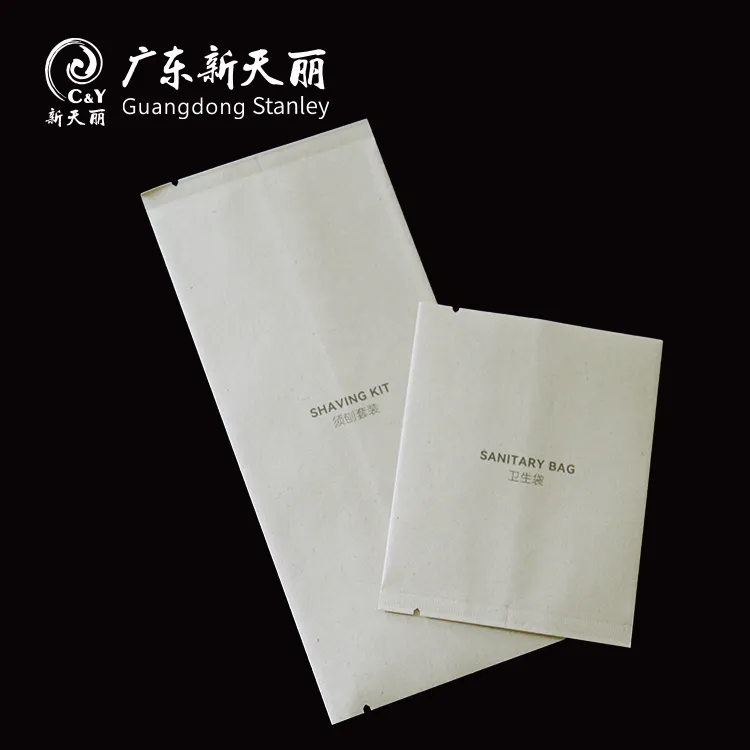

باقة ستانلي توفر مجموعة متنوعة من أنواع الأكياس المعاد تدويرها، بما في ذلك الخدمات المخصصة، ويمكنها اختيار ركيزة الفيلم والتصميم الهيكلي المناسب وفقًا لاحتياجات العملاء. سواء كنت بحاجة إلى عبوات تعقيم بدرجة حرارة عالية أو عبوات حفظ طازجة بدرجة حرارة منخفضة، يمكننا أن نقدم لك أفضل الحلول.

إذا كان لديك أي أسئلة أو احتياجات حول الحقيبة المعاد تدويرها، يُرجى الاتصال بفريقنا المحترف، وسنقدم لك بكل إخلاص الاستشارة والخدمة.