По мере того как растет спрос на безопасность продуктов питания, удобство их хранения и длительный срок годности, ретортные пакеты, как важный материал для современной упаковки продуктов питания, играют все более важную роль. Ретортные пакеты могут не только выдерживать высокотемпературную стерилизацию, но и обладают хорошей герметичностью, барьерной и механической прочностью. Они широко используются для упаковки приготовленной пищи, готовых блюд, мясных продуктов, морепродуктов, супов и других продуктов.

В этой статье мы подробно проанализируем 10 распространенных структур ретортных пакетов и их соответствующие характеристики, чтобы помочь производителям продуктов питания и покупателям упаковки выбрать наиболее подходящую комбинацию структур материалов с научной точки зрения.

Структура PET/Glue/CPP

Это типичная структура прозрачного ретортного пакета с хорошим визуальным эффектом. ПЭТ обеспечивает хорошую жесткость и пригодность для печати, а CPP обладает способностью к тепловому запечатыванию и высокой термостойкостью. Эта структура может быть заменена на PA/клей/PE, а PE может быть заменен на HDPE, LLDPE и MPE.

Благодаря термостойкости полиэтилена, он обычно используется для стерилизации пакетов при температуре около 100~110℃. Обычный полиуретановый клей и кипящий клей могут быть использованы для клея. Он не подходит для упаковки мяса. Барьерное свойство плохое. Пакет морщится после пропаривания, а иногда внутренняя пленка прилипает друг к другу. По сути, эта структура - просто кипящий пакет или пастеризованный пакет.

Структура PET/Glue/CPP

Эта конструкция представляет собой типичный прозрачный ретортный пакет, в который можно упаковать большинство продуктов, готовящихся на пару. Ее характерными особенностями являются хорошая видимость продукта, содержимое можно увидеть напрямую, но она не может упаковывать продукты, которые необходимо защищать от света. На ощупь продукт кажется твердым, и его часто приходится закруглять.

Этот структурный продукт обычно стерилизуется при температуре 121℃, обычный высокотемпературный клей для пропаривания и обычный паровой CPP. Однако клей следует выбирать с небольшим коэффициентом усадки, иначе усадка клеевого слоя приведет к перемещению краски, и есть вероятность расслоения после пропаривания.

Структура BOPA/Glue/CPP

Это обычный ретортный пакет, используемый для стерилизации паром 121℃, с хорошей прозрачностью, мягкостью и хорошей устойчивостью к проколу. Этот продукт не может быть использован для упаковки продуктов, которые необходимо защитить от света.

Из-за высокой влагопроницаемости BOPA при обработке печатной продукции паром легко происходит проникновение цвета, особенно при проникновении на поверхность красок красной серии. В процессе производства в краску часто добавляют отвердители, чтобы предотвратить это. Кроме того, из-за низкой адгезии красок в BOPA легко получить антиприлипание, особенно в условиях высокой влажности. Полуфабрикаты и готовые пакеты в процессе обработки должны быть запечатаны и упакованы.

Структура KPET/Glue/CPP, KBOPA/Glue/CPP

Такая структура используется нечасто. Пакет обладает хорошей прозрачностью и высокими барьерными свойствами, но его можно использовать только для пропаривания и стерилизации при температуре ниже 115°C. Температурная устойчивость несколько ниже, и есть сомнения в его гигиенической безопасности.

Структура ПЭТ/клей/БОПА/клей/КПП

Ретортный пакет такой структуры обладает высокой прочностью, хорошей прозрачностью и устойчивостью к проколам. Из-за большой разницы в усадке между ПЭТ и BOPA он обычно используется для упаковки продуктов при температуре 121°C и ниже.

Если содержимое упаковки содержит кислоту или щелочь, то вместо алюминиевой структуры выбирается продукт с такой структурой. Внешний слой клея может быть изготовлен из вареного клея, и стоимость может быть соответствующим образом снижена.

Структура PET/клей/AL/клей/CPP

Это наиболее типичная структура непрозрачных ретортных пакетов. В зависимости от краски, клея и CPP эта структура может использоваться при температуре приготовления от 121 до 135°C.

- Структура ПЭТ/однокомпонентные чернила/высокотемпературный клей/AL7μm/высокотемпературный клей/CPP60μm может соответствовать требованиям приготовления пищи при температуре 121°C.

- Структура ПЭТ/двухкомпонентные чернила/высокотемпературный клей/AL9μm/высокотемпературный клей/высокотемпературный CPP70μm может быть выше температуры приготовления 121°C, при этом повышается барьерное свойство, а срок хранения увеличивается до более чем одного года.

Структура BOPA/Glue/AL/Glue/CPP

Эта структура похожа на предыдущую, но из-за высокого водопоглощения и усадки BOPA она не подходит для высокотемпературного приготовления пищи при температуре выше 121°C, но обладает хорошей устойчивостью к проколу и может соответствовать требованиям приготовления пищи при температуре 121°C.

Структура PET/Glue/PVDC/Glue/CPP, BOPA/Glue/PVDC/Glue/CPP

Такая структура ретортного пакета обладает отличными барьерными свойствами и подходит для паровой стерилизации при температуре 121℃ и ниже, а также для продуктов с высокими требованиями к барьеру для кислорода.

PVDC в вышеуказанной структуре можно заменить на EVOH, который также обладает высокими барьерными свойствами, но его барьерные свойства значительно снижаются при высокотемпературной стерилизации, а BOPA нельзя использовать в качестве поверхностного слоя, иначе барьерные свойства также резко снижаются при повышении температуры.

Структура PET/Glue/AL/Glue/BOPA/Glue/CPP

Эта структура ретортного пакета является высокопроизводительной структурой, которая может упаковывать почти все продукты, приготовленные на пару, а также выдерживать пропаривание при температуре 121~135℃.

- Структура 1: PET12μm/высокотемпературный клей/AL7μm/высокотемпературный клей/BOPA15μm/высокотемпературный клей/CPP60μm. Эта структура обладает хорошими барьерными свойствами, хорошей прочностью на прокол и хорошей светонепроницаемостью. Это отличный мешок для приготовления пищи на пару при температуре 121℃.

- Структура 2: PET12μm/высокотемпературный клей/AL9μm/высокотемпературный клей/B0PA15μm/высокотемпературный клей/высокотемпературный CPP70μm. В дополнение к характеристикам структуры 1, эта структура обладает свойствами устойчивости к высокотемпературному приготовлению пищи при температуре 121℃ и выше.

- Структура 3: PET/клей A/AL/клей B/BOPA/клей C/CPP, количество клея A составляет 4 г/м, количество клея B составляет 3 г/м', а количество клея C составляет 5~6 г/㎡, что может соответствовать требованиям, уменьшить количество клея A и клея B, и соответственно сэкономить расходы. Другая ситуация заключается в том, что клей A и клей B используют клей с более высокой степенью кипения, а клей C использует клей с высокой термостойкостью, что также может соответствовать требованиям приготовления пищи при температуре 121℃ и снизить затраты.

- Структура 4: ПЭТ/клей/БОПА/клей/АЛ/клей/КПП. Эта структура представляет собой изменение позиции BOPA. Общие характеристики продукта существенно не изменились, но преимущества BOPA, такие как прочность, устойчивость к проколам и высокая композитная прочность, не были использованы в полной мере. Поэтому данная структура используется относительно реже.

Структура ПЭТ/клей/коэкструдированный CPP

Соэкструдированный CPP в этой структуре обычно относится к 5- и 7-слойным CPP с высокими барьерными свойствами, такими как:

- PP/адгезивный слой/EVOH/адгезивный слой/PP

- PP/адгезивный слой/PA/адгезивный слой/PP

- PP/адгезивный слой/PA/EVOH/PA/адгезивный слой/PP

Таким образом, применение коэкструдированного CPP повышает прочность продукта, уменьшает разрушение упаковки при вакууме, высоком давлении и перепадах давления, а также продлевает срок хранения за счет улучшения барьерных свойств.

Рекомендации по выбору структуры ретортных пакетов

При выборе структуры ретортных пакетов необходимо всесторонне учитывать следующие факторы:

- Атрибуты продукта: содержит ли он кости, масло, суп или легко окисляется

- Метод стерилизации: пастеризация, высокотемпературная реторта при 121℃, стерилизация под высоким давлением при 135℃

- Требования к хранению: комнатная температура, охлаждение, светозащита, влагозащита

- Бюджет затрат: баланс между производительностью и ценой

- Требования к внешнему виду: требуется ли прозрачный дисплей и печать высокой четкости

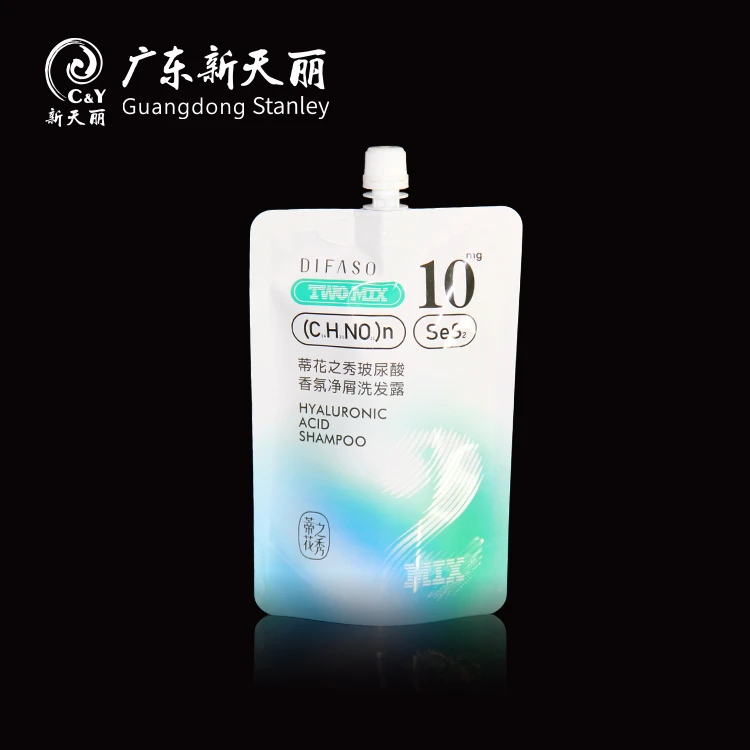

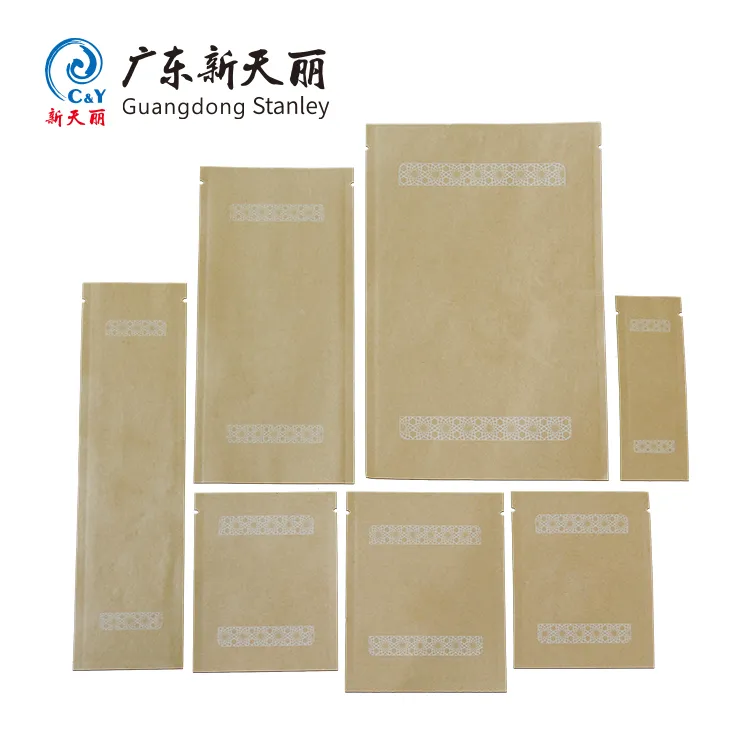

Stanley Package: Ваш надежный партнер по производству ретортных пакетов

В качестве профессиональный производитель гибкой упаковки, Пакет Stanley имеет богатый опыт в разработке структуры ретортных пакетов и может предоставить клиентам:

- Многочисленные варианты функциональных пленочных материалов

- Индивидуальная печать, индивидуальная толщина, индивидуальное количество слоев

- Композитные структурные решения, подходящие для различных условий стерилизации

- Решения для применения пищевых чернил и высокотемпературных композитных клеев

- Быстрая проверка и стабильные поставки больших объемов

Пожалуйста, свяжитесь с нами, чтобы подобрать наиболее подходящее решение для упаковки в реторт-пакеты для вашего продукта.