Безопасны ли вакуумные пакеты для упаковки продуктов питания? Когда речь идет о производителях и торговых марках продуктов питания, вопрос о безопасности пищевых продуктов включает в себя не только материал, из которого изготовлена упаковка, но и соответствие этого материала стандартам безопасности пищевых продуктов и рекомендациям признанных органов по безопасности пищевых продуктов и практики упаковки.

В этой статье мы подробно расскажем о том, что входит в основные требования к сертификации пакетов для вакуумной упаковки и как они соответствуют требованиям безопасности пищевых продуктов.

Почему так важна безопасность пищевых продуктов для вакуумных упаковочных пакетов?

В пищевой промышленности вакуумные пакеты находят широкое применение при упаковке мяса, морепродуктов, молочных продуктов, готовых к употреблению и замороженных продуктов. Хотя продукты становятся безопасными и срок их хранения продлевается с помощью вакуумного процесса, если сам упаковочный материал небезопасен, могут возникнуть риски миграции, запаха и даже нарушений.

Таким образом, главный вопрос, определяющий безопасность вакуумных пакетов для пищевых продуктов, неизменно заключается не в том, запечатаны ли они под вакуумом, а в следующем:

- Какие материалы используются?

- Прошли ли они авторитетную сертификацию в области пищевой промышленности?

- Прошли ли они тщательное тестирование на качество и миграцию?

Основные требования к вакуумным упаковочным пакетам для пищевых продуктов

1. Сырье для пищевых продуктов

Квалифицированные пакеты для вакуумной упаковки обычно изготавливаются из многослойных материалов, таких как PA/PE или PET/PE.

Свойства всех материалов должны соответствовать стандартам контакта с пищевыми продуктами, не содержать вредных веществ и не влиять на вкус и запах продукта.

2. Стабильная герметичность и устойчивость к проколам

Герметичность и устойчивость к проколам - другие факторы, которые, помимо сохранности продуктов, существенно влияют на их безопасность. Протечки при хранении и транспортировке продуктов будут исключены благодаря этому атрибуту.

Общие сертификаты безопасности пищевых продуктов для вакуумных упаковочных пакетов

FDA (Управление по контролю качества пищевых продуктов и лекарственных средств США)

Одобрение FDA - обязательный шаг для выхода на рынок США. Требования FDA были выполнены компанией, что означает, что материалы и обработка вакуумных упаковочных пакетов допускают контакт с пищевыми продуктами.

Правила ЕС по контакту с пищевыми продуктами

В нормативных документах ЕС установлены строгие критерии в отношении количества миграции материалов, которые относятся к продуктам в вакуумной упаковке, продающимся в ЕС, обеспечивая безопасность пищевых продуктов даже после значительного времени воздействия на них.

Система менеджмента качества ISO

Система ISO фокусируется на стабильности и прослеживаемости процессов, и это один из самых важных критериев при определении того, насколько компания, как производитель вакуумных упаковочных пакетов, имеет стабильные возможности поставок.

BRC / HACCP (стандарты, связанные с упаковкой пищевых продуктов)

Эти стандарты в большей степени относятся к управлению цепочкой создания стоимости продуктов питания и связаны с рисками, гигиеной и последовательностью производства продуктов питания. Эти и другие стандарты обычно требуются крупным пищевым брендам в качестве предварительного условия для сотрудничества и партнерства.

Как определить, является ли поставщик вакуумных упаковочных пакетов надежным?

При проведении закупок желательно учитывать следующие факторы:

- Могут ли они предоставить подлинные и прослеживаемые сертификационные документы?

- Проводятся ли у них испытания и контроль качества для каждой партии?

- Обладают ли они опытом настройки и технической поддержки?

- Приоритетны ли для них охрана окружающей среды и производство, соответствующее нормам?

Профессиональный производитель вакуумных упаковочных пакетов не только поставляет продукт, но и обеспечивает надежную упаковку.

Не ограничиваясь безопасностью продуктов питания: Защита окружающей среды не менее важна

В связи с нормативными требованиями и тенденциями заказчики все чаще обращают внимание на снижение содержания летучих органических соединений, экологичное производство и экологически чистые продукты. Внедрение экологичного оборудования и систем помогает компании не только соответствовать нормативным требованиям, но и выполнять свои корпоративные социальные обязательства.

Stanley Package: Надежный партнер по производству гибкой упаковки на заказ

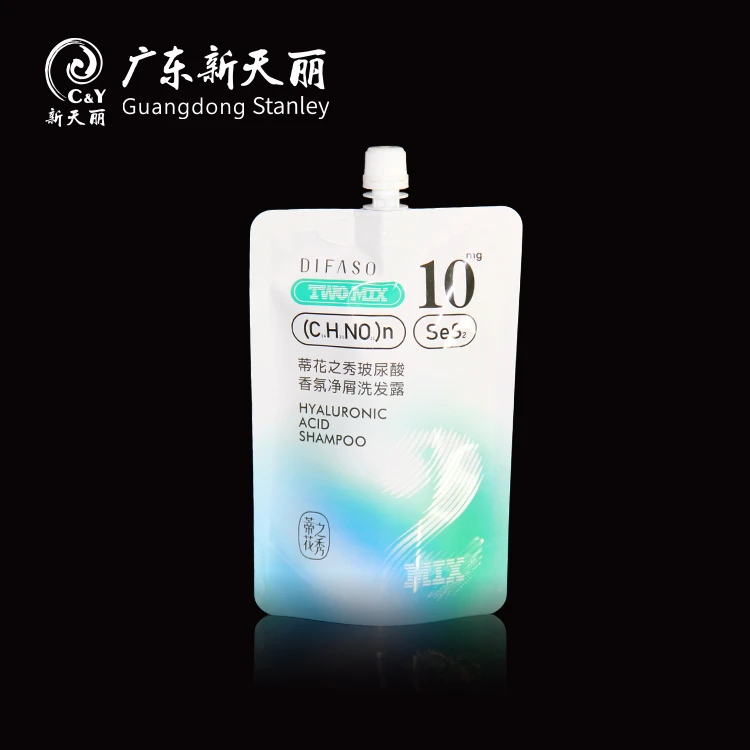

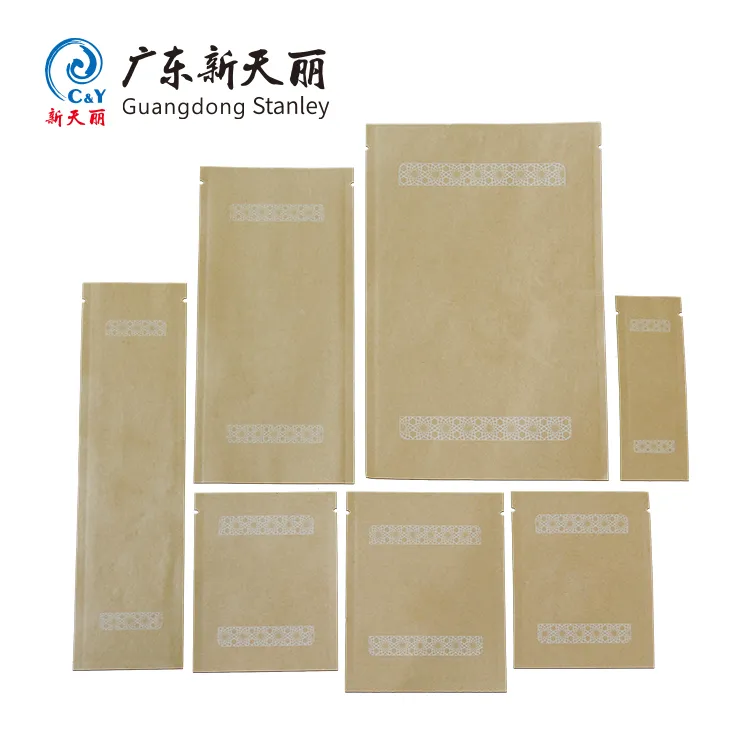

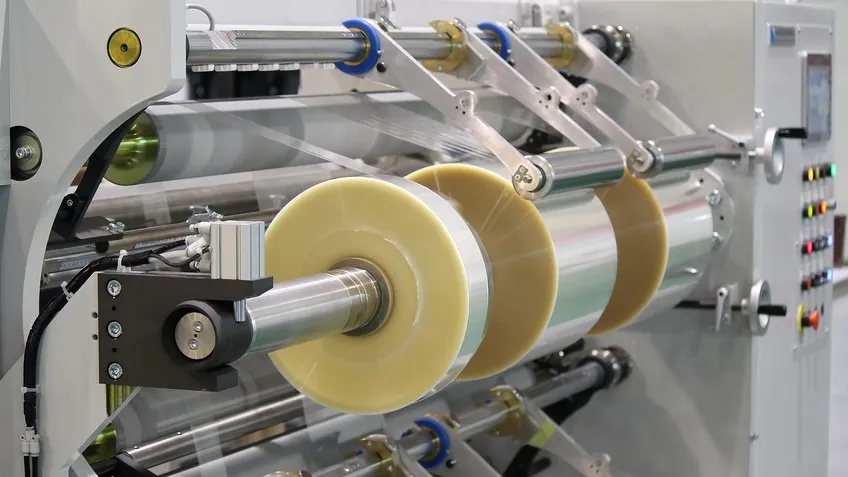

Пакет Stanley Компания была основана в 1998 году и является мировым лидером. Производство гибкой упаковки на заказ. Мы предлагаем ассортимент вакуумные упаковочные пакеты и рулонной упаковочной пленки нашим клиентам по всему миру.

Площадь нашего завода составляет 15 000 квадратных метров, мы располагаем передовым производственным оборудованием и высокоэффективной и экологически безопасной системой RTO для выбросов летучих органических соединений. При этом мы уделяем особое внимание экологичности производства и управлению качеством, сохраняя высокую производственную мощность.

Если вы ищете поставщик безопасных, отвечающих всем требованиям и настраиваемых вакуумных упаковочных пакетов, Stanley Package с нетерпением ждет возможности стать вашим долгосрочным надежным партнером. Свяжитесь с нами, чтобы получить профессиональную консультацию и быстрое предложение.