Der Ausgießerbeutel hat die heutigen verpackten Waren in der Lebensmittel- und Getränkeindustrie sowie in industriellen Anwendungen revolutioniert. Diese fortschrittlichen Verpackungen sind eine Verschmelzung von flexiblen Materialien und leicht zu verteilenden Ausgießern, was zu einer größeren Zufriedenheit der Verbraucher führt. Für ein Unternehmen ist das Wissen um Verfahren zur Abfüllung von Stutzenbeuteln ist im Hinblick auf die Produktqualität, die Sicherheit und die betriebliche Effizienz notwendig. In diesem Artikel werden einige wichtige Methoden und Überlegungen zur korrekten Befüllung von Ausgießerbeuteln vorgestellt.

Schlüssel Füllmethoden

Aseptische Abfülltechnik

Die aseptische Abfüllung ist der Goldstandard für die Verpackung von Beuteln mit Ausgießer, insbesondere für Produkte, die ohne Kühlung länger haltbar sein müssen. Dieser komplexe Prozess umfasst mehrere sorgfältig ausgeführte Schritte: die Reinigung der Beuteloberflächen, das Einsetzen des Ausgießers in einen sterilisierten Bereich mit dünnem Sterilisationsgas, das kurzzeitige Ziehen des Stopfens zum Befüllen des Beutels und das Wiederverschließen vor dem Verlassen der sterilen Umgebung.

Diese Methode gewährleistet vollständige Sterilität während des gesamten Befüllungsprozesses des Ausgussbeutels und verhindert gleichzeitig mikrobielle Verunreinigungen und sorgt für eine hervorragende Produktqualität. Dies ist besonders nützlich für Molkereiprodukte, Säfte und andere Produkte, die empfindlich auf mikrobielle Verunreinigungen reagieren, da die aseptische Abfüllung den Einsatz von Konservierungsmitteln überflüssig macht und dem Produkt eine längere Haltbarkeit verleiht.

Nicht-invasive Füllungstechniken

Fortschrittliche, nicht-invasive Methoden lösen die Herausforderungen bei der Gestaltung von Beuteln mit Auslaufschutzsystemen. Im Gegensatz zu herkömmlichen Ansätzen, bei denen die Düsen physisch durch die Ventile eingeführt werden, positionieren diese Techniken die Fülldüsen extern und nutzen den Druck des Produktflusses, um die Ventilmechanismen während der Befüllung vorübergehend zu öffnen.

Die Verwendung eines nicht-invasiven Abfüllverfahrens bietet zahlreiche Vorteile bei der Abfüllung von Beuteln. Erstens besteht keine Gefahr, dass Kappen oder Ventile durch das physische Einführen des Füllstutzens durch das Ventil beschädigt werden; zweitens werden die Hygienestandards erhöht, indem zusätzliche Punkte für eine mögliche Kontamination beseitigt werden; drittens wird eine größere Zuverlässigkeit beim Befüllen erreicht, was wiederum die Ausfallzeiten optimiert.

Kritische Überlegungen zur Füllung

Optimale Füllhöhen

Die Bestimmung geeigneter Füllhöhen ist für die Leistung und Sicherheit von Ausgießerbeuteln entscheidend. Das Konzept des "Headspace" - des leeren Volumens an der Oberseite des Behälters - bleibt bei flexiblen Verpackungen von entscheidender Bedeutung. Im Allgemeinen wird ein Freiraum von 5-10% empfohlen, um eine Ausdehnung des Produkts während der Verarbeitung oder bei Temperaturschwankungen zu ermöglichen.

Für Spout-Pouch-Anwendungen bedeutet dies in der Regel Füllraten von 90-95%. Ein Überschreiten dieser Werte kann die Integrität der Versiegelung beeinträchtigen, ein Platzen während der thermischen Verarbeitung verursachen oder die Verpackung verformen. Bei unzureichender Befüllung entsteht ein übermäßiger Sauerstoff-Headspace, der zu Oxidation und Produktverschlechterung führen kann.

Strategien zur Luftentfernung

Eine wirksame Luftentfernung bewahrt die Qualität des Ausgießerbeutels und verlängert die Haltbarkeit. Restsauerstoff beschleunigt den Produktabbau durch Oxidation, insbesondere bei empfindlichen Lebensmitteln. Zu den wichtigsten Techniken gehören:

- Vakuumversiegelung: Luftentfernung unmittelbar vor der Versiegelung

- Gasspülung: Verdrängung von Sauerstoff durch inerte Gase wie Stickstoff

- Produktverdrängung: Entwurf von Systemen zur Minimierung von Lufteinschlüssen

Die Umsetzung dieser Strategien verbessert die Schutzfunktionen von Ausgießerbeuteln erheblich und bewahrt die Produktqualität während der gesamten vorgesehenen Haltbarkeitsdauer.

Qualitätssicherung nach der Abfüllung

Versiegelung und Inspektion

Die ordnungsgemäße Versiegelung vervollständigt den Befüllungsprozess des Ausgussbeutels. Die Versiegelungsmethoden müssen sowohl mit dem Beutelmaterial als auch mit den Produkteigenschaften kompatibel sein. Wichtige Parameter wie Temperatur, Druck und Verweilzeit müssen präzise gesteuert werden, um eine gleichbleibende Siegelqualität zu gewährleisten.

Zu den wesentlichen Qualitätstests für Ausgießerbeutelverpackungen gehören:

- Visuelle KontrolleAnalyse von Dichtungen, Ausgussbefestigung und Gesamterscheinung

- FalltestPrüfung der Haltbarkeit unter Bedingungen, die die Handhabung nachahmen

- DruckprüfungPrüfung auf Leckagen oder Berststellen

- Prüfung der HitzebeständigkeitBewertung der Leistung bei Temperaturschwankungen

Operative Vorteile

Optimierte Abfüllprozesse für Stülpbeutel bringen erhebliche Geschäftsvorteile:

- Verbesserte Produktsicherheit: Wenn Fill-to-Seal-Techniken Teil Ihres Produktionsprozesses sind, ist die Wahrscheinlichkeit einer Verunreinigung viel geringer.

- Längere Haltbarkeitsdauer: Durch Entlüftungstechniken kann die Produktqualität erhalten werden.

- Unteres Werbegeschenk: Eine genaue Abfüllung kann die Bestandskontrolle verbessern und mögliche Produktverluste unwahrscheinlicher machen.

- Erhöhter Durchsatz: Rationalisierte Abfüllprozesse können die Effizienz Ihrer Einheit steigern.

- Schutz der Marke: Ein gleichbleibend hochwertiges Produkt ist der Schlüssel zur Erhaltung des Vertrauens der Verbraucher.

Stanley-Paket: Führender Hersteller von Ausgussbeuteln

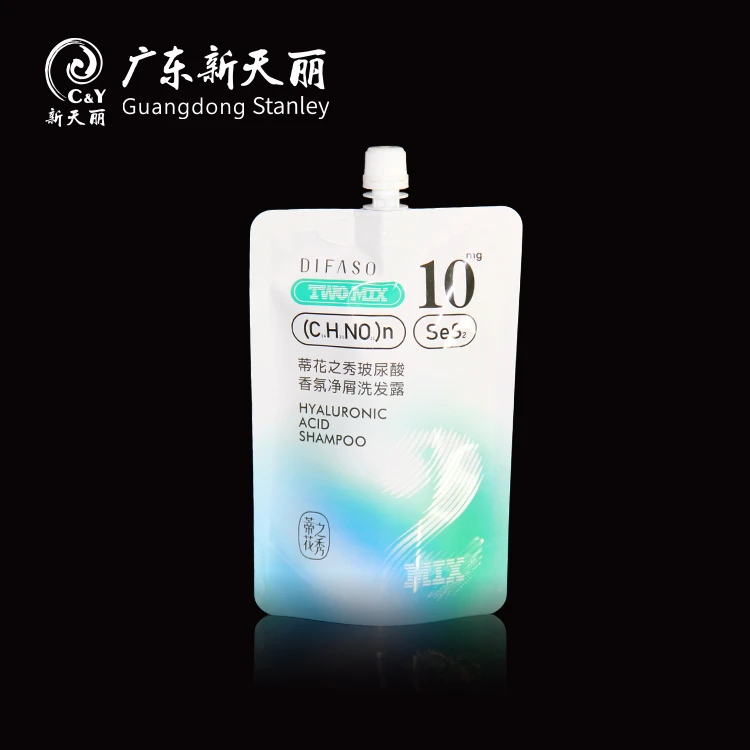

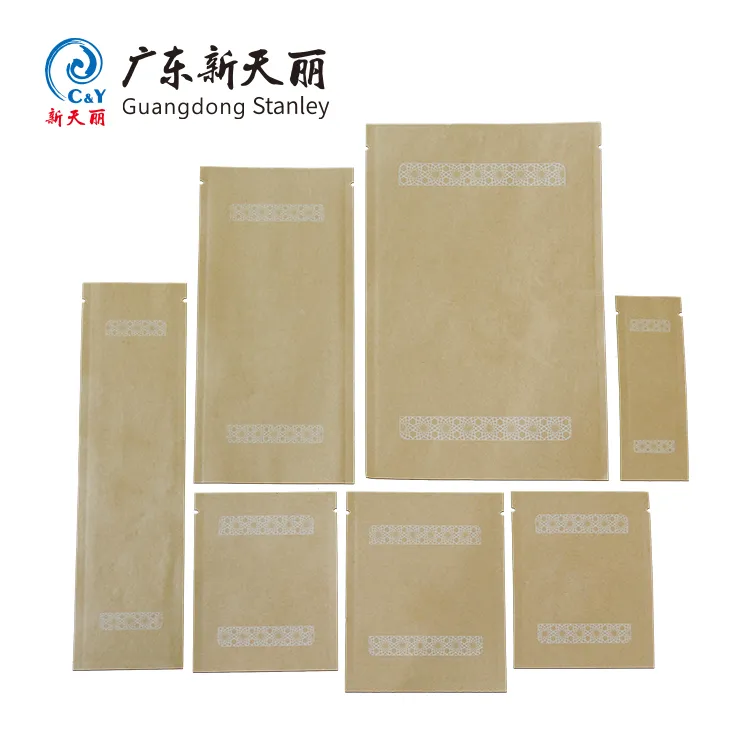

Stanley-Paket ist ein führender Anbieter von kundenspezifischen flexiblen Verpackungslösungen mit mehr als zwanzig Jahren Erfahrung. Unser Unternehmen wurde 1998 gegründet und ist ein globaler Hersteller von Hochwertige Ausgießerbeutel-Designs für verschiedene Branchen.

Unsere Anlage umfasst über 150.000 Quadratmeter Produktionsfläche und setzt die neueste Technologie zur Herstellung flexibler Verpackungen ein, die mit RTO-Systemen auch umweltverträglich ist.

Wir nutzen technisches Fachwissen für eine praktische Designästhetik mit einem Full-Service-Ansatz für Ausgießerbeutel, der auf die spezifischen Anforderungen des Kunden in Bezug auf Befüllung, Versiegelung und Haltbarkeit für Business-to-Business-Anwendungen weltweit zugeschnitten ist.