Dans le marché de consommation actuel, les sachets à fond plat sont devenus la solution d'emballage préférée pour de nombreuses industries telles que l'alimentation, les produits chimiques quotidiens, les produits pour animaux de compagnie et les produits agricoles, en raison de leurs excellentes capacités de présentation en rayon, de leur excellente étanchéité et de la facilité de transport et de stockage qu'ils offrent.

En tant que fabricant professionnel d'emballages flexibles, Stanley offre une solution complète pour les sachets à fond plat, de la conception à la sélection des matériaux, en passant par la production, l'inspection de la qualité et la livraison. Cet article présente en détail l'ensemble du processus de production des sachets à fond plat de Stanley, afin que vous puissiez comprendre clairement chaque étape de l'emballage personnalisé.

Vue d'ensemble de la structure des sachets à fond plat

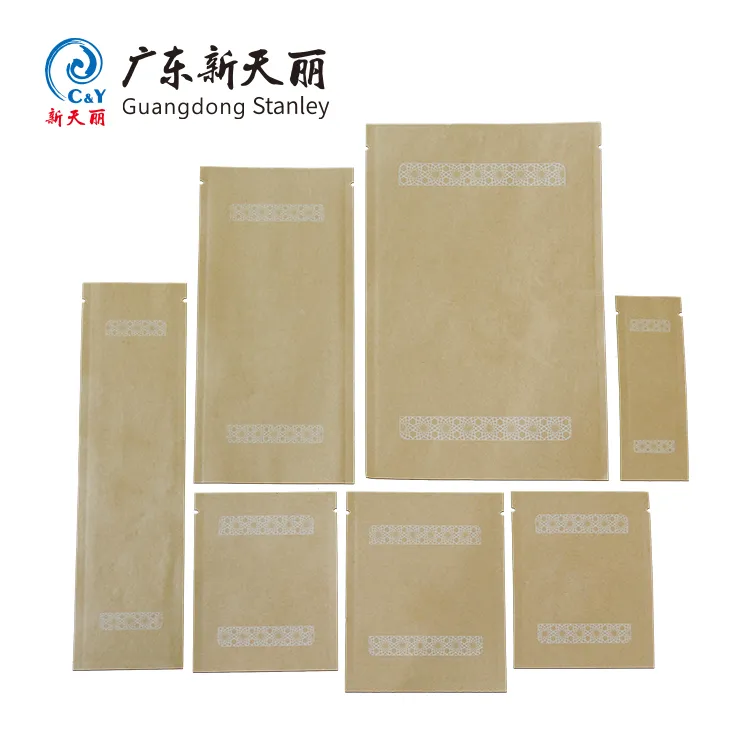

Les sachets à fond plat sont un type de sachet d'emballage qui peut se tenir debout de manière indépendante grâce à la structure du fond. Ils sont principalement constitués de films composites multicouches et présentent les caractéristiques suivantes :

- Scellement du coin inférieur : former une structure de support triangulaire stable afin que le sac puisse tenir sur l'étagère lorsqu'il n'est pas ouvert.

- Structure composite : commun tels que PET/PE, PET/AL/PE, PET/VMPET/PE, etc., utilisés pour assurer l'étanchéité à l'humidité, à l'oxygène, aux UV et d'autres fonctions.

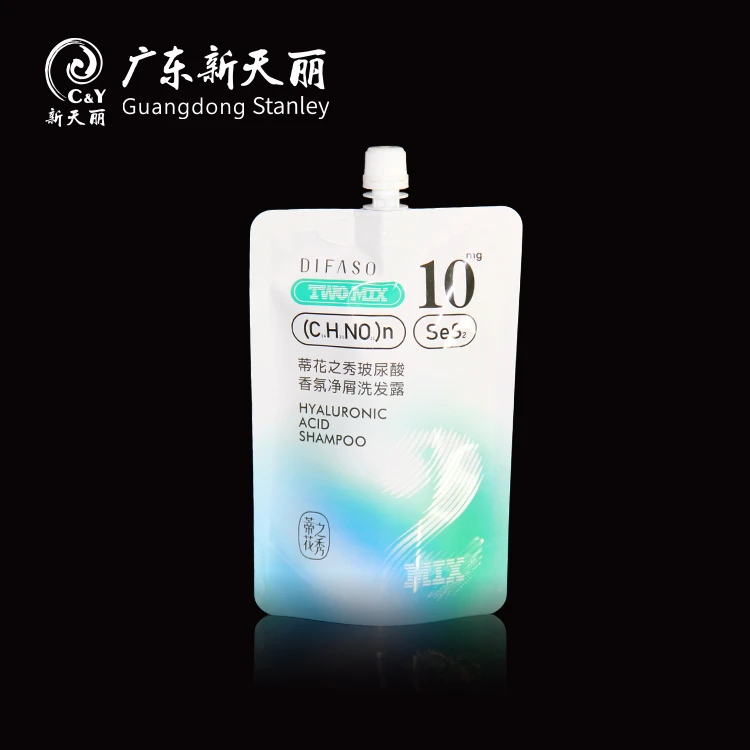

- Fonctions extensibles : des fermetures à glissière, des buses, des encoches d'arrachage, des trous de suspension, des étiquettes anti-contrefaçon, etc. peuvent être ajoutés pour améliorer la commodité d'utilisation.

- Large éventail d'applications : utilisés dans les aliments (noix, café, condiments), les liquides (détergent à lessive, jus), les produits secs, les aliments pour animaux de compagnie, etc.

Processus de personnalisation et de production des sachets à fond plat de Stanley

Stanley dispose d'un système technique mature et d'un équipement de production avancé, permettant la personnalisation de petits lots jusqu'à la production de masse à grande échelle. Voici notre processus normalisé et systématique :

Communication de la demande des clients

La première étape consiste à communiquer pleinement avec les clients afin de s'assurer que nous comprenons bien leurs exigences en matière de fonction, d'apparence et de scénarios d'utilisation des sachets à fond plat. Les principaux contenus sont les suivants :

- Type de produit et utilisation

- Spécifications de capacité et de taille (telles que 100g, 250g, 1L, etc.)

- Exigences en matière de matériaux (si le produit doit être bloqué, résistant aux UV, congelé, etc.)

- Couleur d'impression et maquette (valeur de couleur CMYK/Pantone)

- Exigences particulières (telles que surface de film mate, texture du papier, éclat métallique, etc.)

Conception structurelle et confirmation de la maquette

Les clients peuvent fournir des fichiers de conception (format AI, PDF), et nous pouvons également fournir des suggestions structurelles et des services de mise en page pour s'assurer que le type de pochette est coordonné avec l'effet visuel.

S'il n'y a pas de maquette, notre équipe de conception peut vous aider à développer des motifs, à organiser les éléments de la marque et à définir les spécifications du texte.

Nous pouvons également produire des rendus électroniques ou fournir des épreuves numériques selon les besoins des clients pour confirmer la couleur, le matériau et la structure fonctionnelle.

Impression et plastification

Une fois la conception confirmée, le processus d'impression commence. Stanley est équipé d'une machine d'impression par héliogravure à grande vitesse :

- Impression fine multicolore (jusqu'à 10 couleurs)

- Effets spéciaux tels que motif complet, marquage à chaud partiel, marquage argenté à froid, etc.

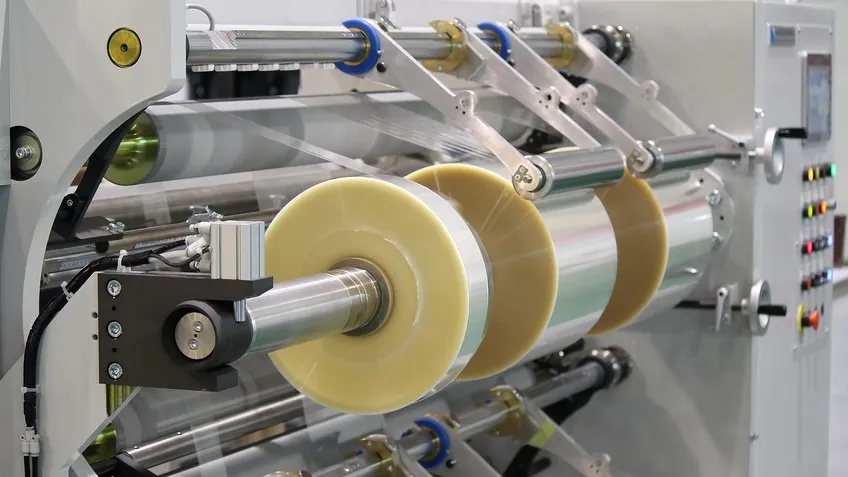

Après l'impression, les matériaux sont stratifiés. Choisissez en fonction de vos besoins :

- Pelliculage à sec

- Pelliculage sans solvant

- Laminage par extrusion

Cette étape permet de s'assurer que les différentes couches de matériaux fonctionnels sont bien ajustées et d'améliorer les propriétés physiques (imperméabilité à l'eau, à l'huile, aux gaz, etc.).

Mûrissement et tranchage

Les matériaux stratifiés doivent être guéris (48-72 heures) afin de permettre à la couche adhésive de durcir complètement et d'améliorer la stabilité du matériau. Ensuite, le matériau est découpé avec précision dans la largeur de rouleau requise pour la production, prêt à entrer dans le processus de fabrication du sac suivant.

Fabrication et moulage de pochettes

La fabrication d'un sac est une étape clé pour obtenir la structure d'un sac autoportant. Nous utilisons des machines automatiques de fabrication de sacs à grande vitesse pour :

- Sceller à chaud le fond du sac et poinçonner les coins pour former une structure autoportante.

- Installer des accessoires fonctionnels (fermetures à glissière, buses, trous de suspension, etc.)

- Ajouter des bords faciles à déchirer et un gaufrage des bords pour améliorer l'expérience du consommateur.

Contrôle de la qualité

Nous mettons en œuvre un certain nombre de procédures normalisées d'inspection de la qualité, notamment :

- Essais de résistance du joint thermique et d'étanchéité à l'air

- Test de chute, test de congélation

- Essais de déviation de l'impression et de stabilité des couleurs

- Contrôle de l'apparence (présence de bulles, de plis, de fuites d'encre d'impression, etc.)

Chaque lot de marchandises est accompagné d'un rapport d'inspection et applique strictement les normes de l'usine.

Emballage et livraison

Les produits qualifiés sont conditionnés selon les besoins, et vous pouvez choisir :

- Emballage en vrac

- Emballage selon les quantités spécifiées par le client

- Avec des étiquettes, des codes-barres, des codes QR et d'autres étiquettes d'information

Nous prenons en charge la distribution logistique mondiale et le cycle de production normal est de 12 à 18 jours ouvrables (en fonction de la complexité et de la quantité de personnalisation).

Pourquoi choisir Stanley ?

Les avantages concurrentiels de Stanley sont les suivants :

- Plus de 20 ans d'expérience dans la personnalisation des emballages souples

- Service d'usine unique, depuis la conception, l'impression, la fabrication des sacs jusqu'à l'inspection de la qualité

- Soutenir une variété d'options de matériaux respectueux de l'environnement, tels que les films dégradables et recyclables.

- Répondre rapidement aux exigences d'épreuvage et de livraison de petits lots

- Une équipe professionnelle pour suivre le projet tout au long du processus afin d'assurer la satisfaction du client.

Conclusion

Une pochette de haute qualité est le résultat d'innombrables vérifications de la conception, du polissage des processus et de la gestion du contrôle de la qualité. Avec une équipe professionnelle et un système de fabrication complet, Stanley fournit des solutions d'emballage flexibles, efficaces et fiables pour les marques internationales.

Si vous êtes à la recherche d'un fabricant fiable de sachets à fond platn'hésitez pas à contacter Stanley. Nous sommes prêts à fournir le support d'emballage flexible le plus adapté à votre marque !