在软包装行业,铝箔袋作为一种高效、多功能的包装解决方案,已成为保护不同类型产品的首选屏障。对于食品、药品、电子产品和工业产品,铝箔袋可提供全面的保护,延长产品的保质期并保证质量的一致性。

作为一家成立于 1998 年的专业软包装制造商,史丹利包装多年来一直致力于铝箔袋的研发和生产,并为世界各地的客户提供了优秀的包装解决方案。

什么是铝箔袋?

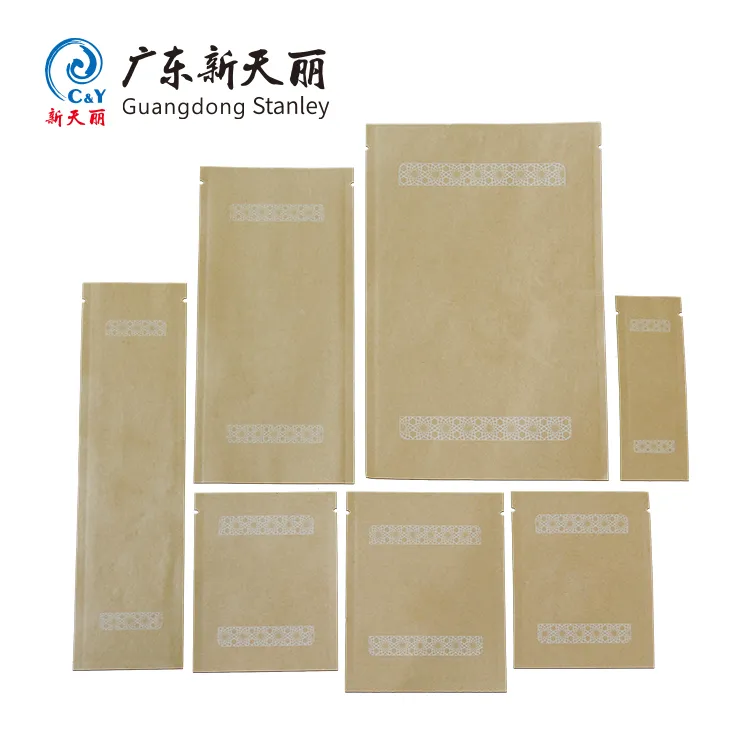

铝箔袋是由多层塑料薄膜复合而成,并通过制袋机进行加工。铝箔袋通常有四层结构,具有良好的阻水和阻氧性能。可定制的包装袋有各种尺寸和样式,包括直立袋、三边封袋、喷嘴袋、平底袋和风琴袋。

常见的材料组合包括 PET/AL/PE、PET/NY/AL/PE 和 PET/NY/AL/CPP。在这些复合包装中,塑料的柔韧性与铝箔的阻隔性融为一体,是一种理想的包装材料。

铝箔袋的卓越功能

卓越的阻隔性能

铝箔袋具有优异的空气阻隔性能,能有效防止氧化、水和湿气。其独特的结构形状可完全隔离光线、氧气和湿气,为内装物提供全面保护。

卓越的机械性能

铝箔袋具有出色的抗爆性、抗穿刺性和抗撕裂性,因此在运输和使用过程中可承受无数外力,确保包装的完整性。

卓越的耐热性

铝箔袋耐高温(121°C)和低温(-50°C),适用于消毒和冷冻储存环境,应用范围广泛。

卓越的香味保存

铝箔袋能有效地保持产品原有的风味和香味,而不会削弱产品的风味或传递产品的香味,因此特别适用于食品和化妆品包装。

安全与环境保护

铝箔袋无味无毒,符合食品和药品包装的卫生标准,以及欧盟和北美包装材料最严格的环保要求。

铝箔袋的应用

食品工业

铝箔袋广泛用于包装牛奶、大米、肉类、鱼干、水产品、腌肉、烤鸭、烤鸡、烤猪肉、冷冻食品、火腿、腌肉、香肠、熟肉、酱菜、豆瓣酱和调味品,能很好地保持食品的香气、品质、风味和色泽。

在食品行业,铝箔袋能有效保持食品的香味和口感,并延长其保质期。从咖啡、茶、巧克力、饼干等日常食品到传统美食,铝箔袋都是理想的包装。

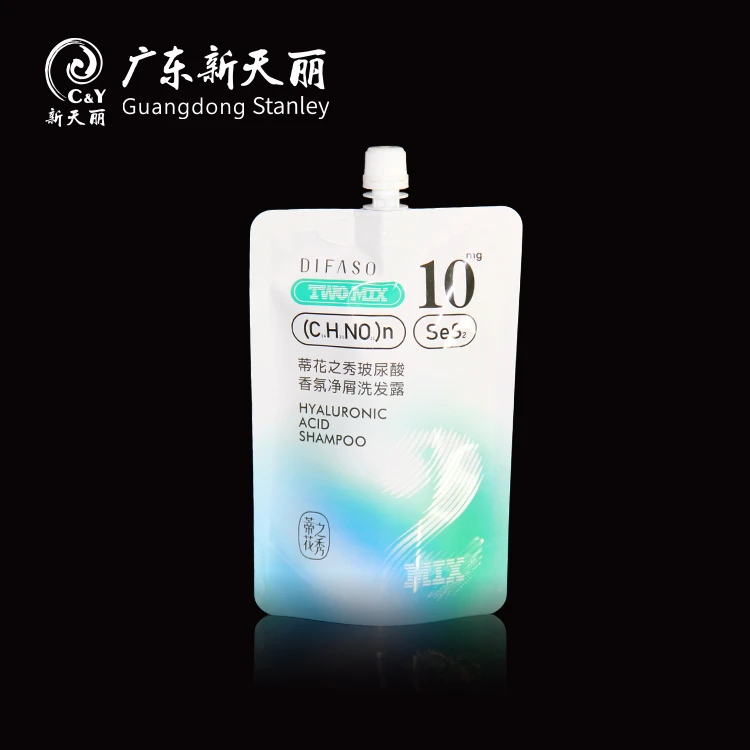

化妆品包装

在化妆品行业,铝箔包装袋通常用于包装奢侈化妆品,保护其成分不受潮湿和空气的影响,以延长其保质期。化妆品的有效成分容易受环境影响而发生变化,铝箔包装袋是保证其安全的理想解决方案。

制药业

铝箔袋广泛应用于制药业,用于包装片剂、粉剂和中药等药品,保持其防潮和氧化稳定性,从而保证其药效和稳定性。医药包装的标准非常高,而铝箔袋符合医药行业的标准。

电子产品包装

铝箔袋可用于包装各种电路板、电子产品、精密机械零件、消费品和工业产品,如 PC 板、集成电路 (IC)、电子元件、用于各种 LED 应用的表面贴装 (SMT) 贴片、灯带包装、精密五金件和汽车配件。

在电子产品市场,铝箔袋可以保护电子产品免受辐射和静电影响,保证其质量和性能。

斯坦利包装铝箔袋的优势

作为 领先的软包装制造商, 斯坦利套餐铝箔袋具有以下独特优势:

定制服务

我们能够根据客户的个性化要求提供完全定制的铝箔袋解决方案,如不同规格、样式和功能的包装袋。无论尺寸、厚度或特殊功能如何,我们都能满足。

质量保证

所有产品均按照 GB 和 ASTM 标准进行测试,符合环保要求(可提供第三方测试报告)。它们符合欧盟和北美最严格的包装材料环保标准。

技术支持

我们的技术团队拥有 20 多年的行业经验,可以为客户提供专业的技术建议和服务,帮助他们选择最合适的包装解决方案。

全球供应

作为一家国际软包装制造商,我们有能力服务于全球市场,也能对全球客户的要求做出快速反应。

铝箔袋市场前景

随着人们对产品包装要求的不断提高,铝箔袋市场正经历着持续增长。根据市场调研,全球软包装市场预计将从 2025 年的 $2,708.3 亿美元增长到 2032 年的 $4,061.4 亿美元,这反映出人们对高性能包装解决方案的需求不断增长。

软包装也是其所有应用中最大的终端市场,食品和饮料行业大量使用软包装来包装饮料、肉类、乳制品、糖果、零食等。铝箔袋在这一行业中发挥着重要作用。

结论

作为一种多功能、高性能的包装材料,铝箔袋已成为现代包装业不可或缺的一部分。由于其卓越的阻隔性能、机械强度和环保性,铝箔袋已成为众多行业的首选包装材料。

自 1998 年成立以来、 斯坦利套餐 专业从事软包装产品的研究、开发和制造,致力于为全球客户提供最优质的产品和服务。

无论是包装食品、电子产品、药品还是化妆品,我们都能提供最合适的铝箔袋解决方案,为产品提供完美保护,延长保质期,提升品牌价值。

选择 斯坦利套餐 就是选择质量、可靠性和创新。让我们一起为您的产品提供最优质的包装保护!