Flexible packaging has emerged as the most popular packaging option for brands across most industries in the consumer goods industry today. It is not only lightweight, strong, and transportation cost-reducing, but also has strong customization capabilities. Flexible packaging can be applied to a vast array of industries such as food, health care products, cosmetics, pet supplies, and daily chemicals. So, how is a high-quality flexible packaging bag made?

As a professional flexible packaging manufacturer, Stanley Package provides full-process services from material development, printing design, lamination, slitting to finished bag making for global customers. Below, we will take you to learn more about the manufacturing process of flexible packaging.

Material selection: customize the best structure for the product

The performance of flexible packaging depends largely on the composite material used. Stanley provides a variety of film structures to meet the needs of different products for barrier properties, fragrance retention, moisture resistance, etc. Commonly used materials include:

- PET (polyester film): high strength, heat and oil resistance, suitable for outer layer printing

- PE (polyethylene): soft, good sealing, often used as inner heat sealing layer

- BOPP (biaxially oriented polypropylene): light weight, good transparency, high stiffness

- Aluminum foil/aluminized film: excellent barrier properties, used for products that are highly sensitive to oxygen and water vapor

- Degradable film: PLA, recyclable PE/PP and other environmentally friendly materials

We design the optimal material structure for customers based on product characteristics, packaging form, shelf life and budget.

Printing stage: create brand visual identity

Flexible packaging is not only the “outerwear” to protect the product, but also an important carrier of brand image. Stanley is equipped with advanced printing equipment to provide customers with:

- Gravure Printing: high-precision pattern printing, supporting up to 10-color printing, suitable for large-scale, high-quality requirements

- Flexo Printing: suitable for environmentally friendly ink and small-batch customization

- Digital Printing: fast proofing, suitable for multi-SKU products and new product development stages

We use food-grade inks in the printing process to ensure bright colors and clear layers, while taking environmental protection and safety into consideration.

Composite (Lamination): Multi-layer material performance integration

By laminating materials with different functions together, better comprehensive performance can be obtained. Stanley provides three composite methods for flexible packaging:

- Solvent-based composite: suitable for high barrier requirements

- Solvent-free composite: environmentally friendly and energy-saving, suitable for food, daily chemicals and other odor-sensitive applications

- Water-based composite: used for specific environmentally friendly packaging projects

Through scientific proportions, we organically combine the printing layer, protective layer, and sealing layer to create a pressure-resistant, cold-resistant, heat-resistant, oil-resistant, and puncture-resistant packaging structure for customers.

Ripening and slitting: let the material enter a “stable state”

The composite flexible packaging material needs to be ripped to ensure that the glue is fully cured and the layers are firmly bonded and not delaminated. Then enter the precision slitting process to accurately cut the large roll material into small rolls according to the product size to ensure that the tension of each roll film is consistent and without deflection.

Bag making: flexible and diverse packaging forms

In the entire production process of flexible packaging, “bag making” is the key process to convert roll film materials into final usable packaging bags. Different product types, market positioning and usage requirements determine the functional structure, opening method, capacity and load-bearing capacity of the packaging bag. Stanley Package has advanced fully automatic bag making equipment and a professional technical team, which can produce various types of bags according to customer needs to meet different application scenarios such as retail, industry, food, health products, and liquids.

The main bag types we support include:

Stand Up Pouch

- With a bottom support structure, the bag body can stand vertically to improve the shelf display effect.

- It can be equipped with zipper, resealable, easy-tear design, suitable for nuts, snacks, health powder, coffee, pet food, etc.

- Matt film, aluminum foil, transparent window, metallic glossy film and other materials can be selected to enhance the brand sense.

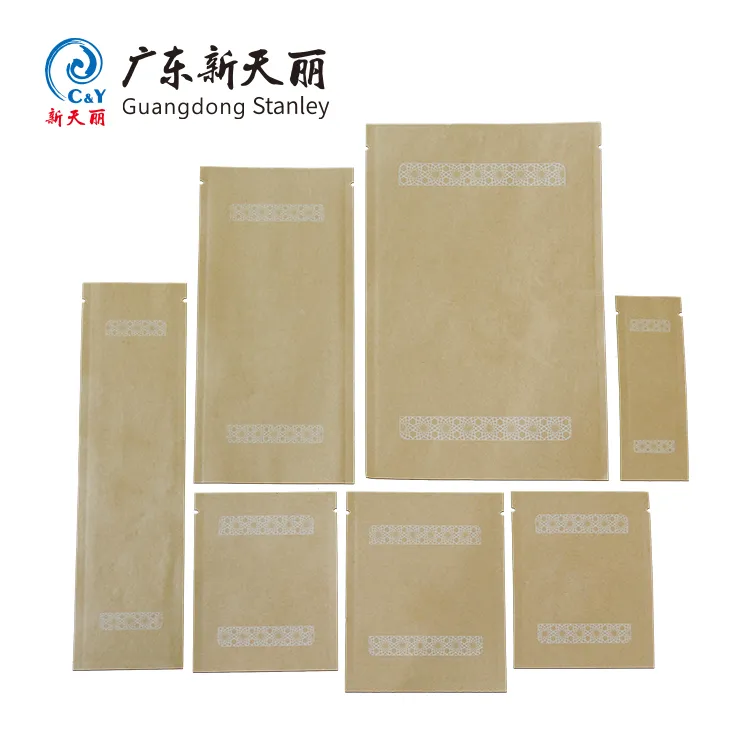

3-Side Seal Pouch

- Simple structure, low cost, suitable for flat products, single small packages.

- Can be used as an inner bag and outer packaging for easy transportation and storage.

- Commonly used for trial packs, granular foods, wet wipes, desiccants, pharmaceutical samples, etc.

Zipper Pouch

- Enhance the reusability and sealing of the packaging and extend the shelf life.

- Zipper structures include standard zippers, invisible zippers, double-track zippers and other types.

- Can be used with stand-up bags and special-shaped bags, combining functionality and aesthetics.

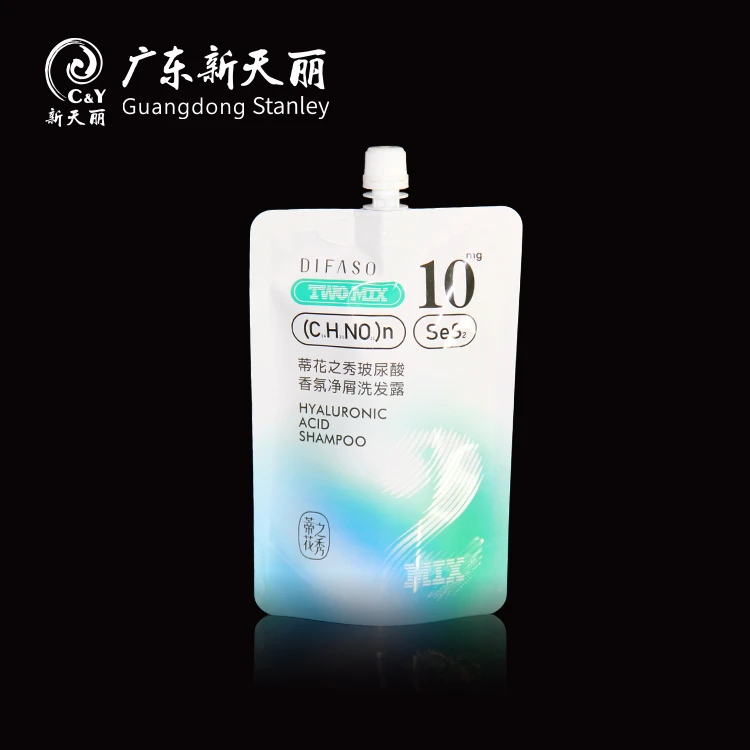

Spout Pouch

- Designed for liquid or thick products, such as juice, puree, baby food, laundry detergent, sports drinks, etc.

- The spout can be heat-sealed and screwed on for easy pouring, carrying and sealing.

- Handle holes and hanging holes can be added for easy carrying and display.

Shaped Pouch

- Through die design, personalized bag shapes can be achieved, such as animal shapes, bottle shapes, water drop shapes, etc.

- Suitable for children’s food, cosmetic samples, brand promotion products, etc., to enhance user memory points.

- Supports high-end printing technologies such as window, matte UV process, local gloss, etc.

Flat Bottom Pouch / Box Pouch

- The bag is wide and has five-sided printing areas, which provides more display space.

- The bottom + two sides have a total of eight sealed edges, with strong load-bearing capacity, suitable for high-end cereals, coffee, pet food, etc.

- Can be matched with zippers, valves, easy-tear mouths and other multi-functional structures.

Vacuum bag / aluminum foil bag

- Suitable for products that require vacuum or strong barrier, such as pickled products, dried goods, Chinese herbal medicine, baking ingredients, etc.

- The multi-layer composite structure effectively isolates oxygen, water vapor, and ultraviolet rays to keep the product fresh.

- The surface can be made of matte, anti-slip pattern, and metallic film to enhance the texture.

Optional functional components and processing options

- Transparent window: convenient for consumers to view the contents and improve purchasing confidence

- Laser tear-off: easier to open and better user experience

- Hanging hole / hand hole: convenient for terminal retail display or carrying

- Valve (Degassing Valve): used for products such as coffee that require gas release

- Local UV / matte film / metal film treatment: enhance packaging texture and brand recognition

Customized service advantages:

At Stanley Package, we not only provide standard bag types, but also tailor-made exclusive flexible packaging solutions for you according to the customer’s product attributes, usage scenarios, and brand positioning. Whether you need a high-end eight-side sealed coffee bag, a convenient and practical zipper stand-up bag, or a unique and eye-catching special-shaped bag, we can provide you with proofing, mass production and compliance certification support.

Quality inspection and packaging shipment: quality assurance at every step

The finished bag must undergo strict quality inspection before leaving the factory, including:

- Appearance and size inspection

- Heat seal strength test

- Barrier performance test (oxygen, water vapor transmission rate)

- Drop and pressure resistance test

- Food contact safety test (if necessary)

Stanley insists on international standard production and supports SGS, FDA, ISO, LFGB, EU standard testing to ensure that the flexible packaging is safe, reliable and in compliance with the regulatory requirements of various countries.

Why choose Stanley Package?

As a company focusing on flexible packaging manufacturing, Stanley Package not only provides standardized product services, but also excels in flexible customization according to customer needs. Our advantages include:

- One-stop service: from structural design to finished packaging, full process control

- Fast proofing: support small batch trial orders and proofing to speed up the time to market

- High customization: size, structure, function, and printing pattern can all be customized

- Multi-industry adaptation: food, health products, pet products, cosmetics and other full categories

- Green and sustainable: optional environmentally friendly materials, recyclable structure, carbon footprint optimization solutions

Conclusion: Let packaging add points to the brand

Flexible packaging is not only a material solution, but also an important tool to promote brand upgrades and enhance user experience. Stanley Package always adheres to professional manufacturing capabilities, flexible customization solutions and strict quality management to help customers stand out in the market.