In today’s globalized market, custom flexible packaging has become an indispensable component of a diverse range of industries, from food and beverages to pharmaceuticals, from household chemicals to industrial goods. As a protective, flexible, and aesthetically pleasing packaging form, custom flexible packaging not only effectively protects product contents and provides shelf life to the product, but also boosts brand image and generates sales through attractive print and design.

With evolving consumer preferences and growing environmental awareness, the custom flexible packaging industry is undergoing profound transformation, moving towards greater intelligence, personalization, and environmental friendliness. This article will delve into the latest trends, technological innovations, and future prospects for custom flexible packaging, providing valuable insights for industry practitioners and stakeholders.

Market Status and Size

The custom flexible packaging market worldwide remains on an upward trend, showing tremendous potential. According to market reports, the size of China’s plastic flexible packaging market will be 109.004 billion yuan in 2023, increasing by 4.9% year on year. Global liquid flexible packaging market size was $2.671 billion in 2024 and is expected to reach $3.797 billion by 2031, growing at a CAGR of 5.3%. This expansion is driven by consistent demand from other downstream industries, primarily the food and beverage industry that has the largest application market for flexible packaging.

In addition, pharmaceutical and daily chemical industry demand for high-barrier and high-performance packaging, etc., are also driving market growth. The customized flexible packaging possesses the features of light weight, good plasticity, good barrier property, and good odor-locking and freshness-preserving performance. It also possesses good load-carrying and protective performance, has good distribution and consumption convenience, has good sales promotion, and good product added value.

Material Innovation and Technology Trends

Custom flexible packaging innovation is largely evidenced in the rapid advancements in material technology. As environmental regulations become tighter everywhere in the world, the application of recyclable mono-material constructions and bio-based films is accelerating and driving the business toward a circular economic model.

For example, the EU Green Deal and the Circular Economy Action Plan mandate all packaging to be economically recyclable or reusable by 2030. This has made monomaterial a top trend for flexible packagers.

From a material performance perspective, the sector is attempting to reconcile weight reduction and barrier function. Weight-reduced, high-performance monomaterial packaging like composite structures of polyethylene (PE) or polypropylene (PP) can be recyclable while providing better oxygen and moisture barriers that ensure product freshness and safety.

Meanwhile, biodegradable materials such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are increasingly being used in custom flexible packaging, although their cost and technical maturity still require improvement.

Technological innovation extends beyond the materials themselves to production processes. For example, to address environmental pressures from volatile organic compound (VOC) emissions, leading manufacturers are introducing highly efficient and environmentally friendly technologies such as regenerative thermal oxidizers (RTO).

Rotary RTO technology VOC removal efficiency is more than 99%. The technology also recovers heat to provide production equipment with heat, reducing the overall consumption of energy and typically achieving a payback period of 3-5 years. The technology not only meets the demands of emission standards but also maintains this achievement, balancing environmental and economic interests.

Environmental Requirements and Sustainable Development

Sustainability is becoming a big issue for custom flexible packaging firms these days. Increased pressure from consumers and the government to offer sustainable packaging is prompting businesses to bring greener, more environmentally friendly production methods. As mentioned above, recyclability and biodegradability of materials are important, but being eco-friendly means more than that.

It is important to reduce carbon emissions and the production of waste in the manufacturing process. For example, use of RTO technology for treatment of VOC emissions enables manufacturers to reduce their environmental footprint. Furthermore, light design is sought in the industry to reduce plastic use and promote recycled material use. Some of the large corporations strive for “zero landfill” targets and reducing carbon footprint by using renewable energy.

Environmental controls also continue to evolve, placing greater pressure on industry. The 2025 Pharmacopoeia of the People’s Republic of China significantly increases the quality level of pharmaceutical packaging materials, imposing stricter requirements for protection, compatibility, safety, and performance.

Similarly, the EU’s Green Deal is reforming global value chains. Specialist flexible packaging producers therefore need to keep a watching brief for policy and look forward in order to achieve compliance and harvest market potential.

Intelligent and Functional Development

Intelligent packaging is another emerging frontier for the custom flexible packaging industry. Through the integration of information technology, packaging now no longer simply passively safeguards products but can actively interact with consumers and provide value add.

For example, smart labels (such as freshness and time-temperature indicators) can monitor product condition in real time to ensure food quality and safety. Radio frequency identification (RFID) and near-field communication (NFC) enable supply chain visibility and product tracking, avoiding counterfeit and poor-quality products and enhancing consumer trust.

Functionally, custom flexible packaging is becoming increasingly diverse to fulfill specific functions. For example:

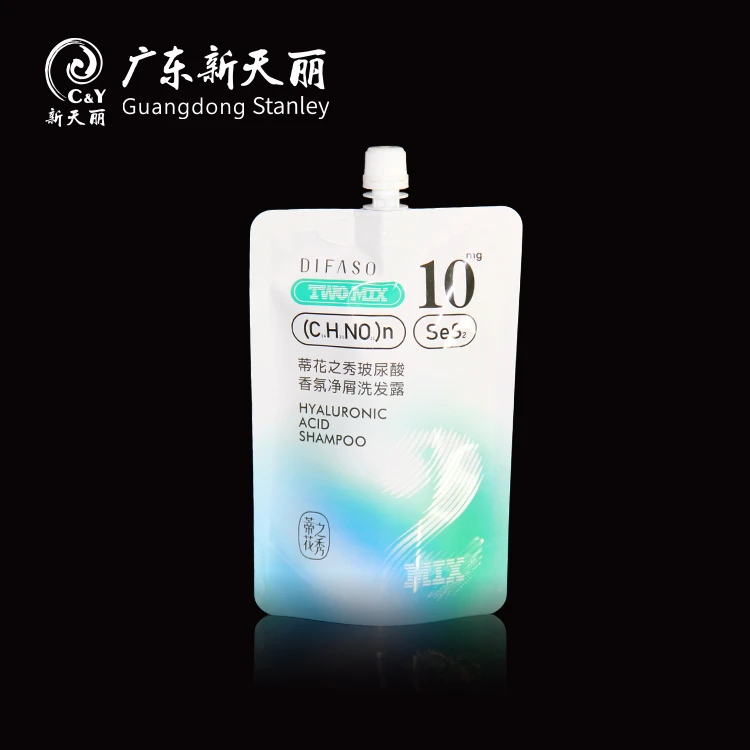

- Spout Pouches: They facilitate multiple dispensations of liquid and viscous products and are extensively used in the area of beverages, wet foods, and daily essential needs.

- Stand-up Pouches: They are good at shelf-stability and shelf-sustainability and are extensively used in the application of snacks, coffee, and pet food.

- Vacuum Pouches: Their high-tech barrier properties enable long-term freshness in the application of a vacuum-sealed atmosphere and are extensively used in meat and cheese applications.

These functional designs not only enhance the user experience but also create a differentiated competitive advantage for companies.

Challenges and Strategies

While the custom flexible packaging industry has promising prospects, it is also faced with a range of challenges. To begin with, the volatility of raw material prices and the uncertainty of supply chains can impact the production cost and lead times. Secondly, green technologies entail enormous up-front investments; e.g., capital-expensive installations of RTO systems. Also, the industry is highly competitive, especially in nations such as China, where there are numerous firms but the majority are small-scale and with little innovation capability.

To address these challenges, companies can adopt the following strategies:

- Increase R&D Expenditure: Innovate continuously in materials, processes, and products to meet market demand for high-performance and eco-friendly packaging.

- Optimize the Supply Chain: Reduce raw material price volatility and geopolitical risks through diversified sourcing and strategic inventory management.

- Invest in Environmentally Friendly Technologies: While costly initially, technologies like RTO can yield economic and environmental dividends in the long term, allowing a payback period of several years through energy recovery.

- Quality and Compliance: Enforce a rigorous quality management system for products to satisfy domestic and foreign standards and regulations, e.g., standards for packaging materials for pharmaceuticals in the 2025 edition of the Chinese Pharmacopoeia.

Conclusion

The custom flexible packaging market is undergoing innovation and development. The market demand is still increasing, technology continues to develop, and protection of the environment and sustainable development are the primary driving forces. Greater emphasis will be given to the recyclability and biodegradability of the material in the future, smart packaging will be more interactive and traceable, and efficient and environmentally friendly production technologies will be the standard.

Faced with all these challenges, companies have to respond in a flexible manner, drive innovation, simplify operations, and always prioritize quality and environmental sustainability. Only by doing so can we distinguish ourselves in the highly competitive marketplace and create long-term value for global consumers and the environment.

About Stanley Package

Stanley Package is a global trusted custom flexible packaging manufacturer, established in 1998. With high-level production equipment and excellent quality control system, the company offers customers worldwide a full range of packaging pouches and roll stock packaging films.

Stanley Package‘s 15,000 square meter factory is equipped with the latest production equipment and backed by an extremely energy-saving and eco-friendly RTO (Regenerative Thermal Oxidizer) system to govern VOC emissions, enabling green manufacturing while reducing the efficiency of operation.

Through continuous technological innovation and a commitment to sustainable development, Stanley Package is committed to providing customers with high-quality, environmentally friendly custom flexible packaging solutions, helping them enhance product value while reducing environmental impact.

Flexible Packaging Supplier for Every Product Need

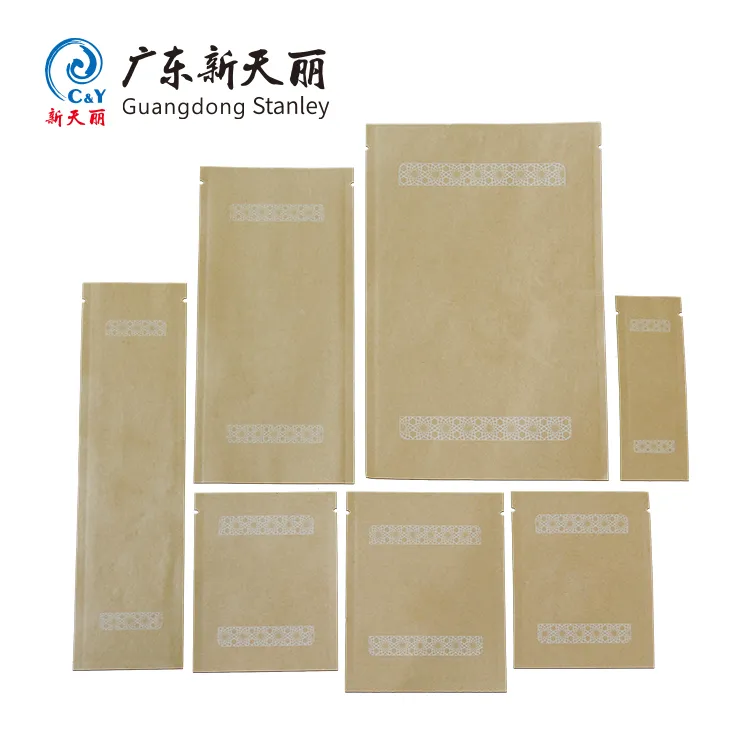

As a roll stock film & packaging pouch manufacturer with over 20 years of experience, Stanley specializes in designing and manufacturing flexible packaging bags and roll stock films to meet the unique needs of your products and brands.

Whether it is snacks, beverages, coffee, ready meals, cosmetics, skin care products, detergents, pharmaceuticals, pet products, or industrial products, we can provide customized packaging to ensure that your brand stands out.

FAQs About Custom Flexible Packaging

Q1: What is custom flexible packaging?

Custom flexible packaging refers to flexible packaging material that is customized according to individual customer specifications. It is generally made up of composite materials such as plastic film, aluminum foil, or paper. It possesses the properties of being light in weight, high plasticity, and good barrier property. It is extensively used in food, beverage, pharmaceutical, and daily chemical industries for product protection, shelf life, and brand image enhancement.

Q2: How does RTO technology benefit flexible packaging production?

RTO (Regenerative Thermal Oxidizer) is a highly efficient VOC treatment system. It destroys volatile organic compounds through high-temperature oxidation with over 99% purification efficiency. RTO recycles heat energy to be utilized in the production process, which is energy-saving. The investment will usually be returned within 3-5 years, with environmental and economic win-win.

Q3: What are the key trends driving the custom flexible packaging industry?

Key trends include: growing demand for recyclable and biodegradable materials (such as single-material construction); the integration of smart packaging technologies (such as freshness indicator labels and RFID); and stricter environmental regulations requiring sustainable practices. Lightweight and functional design are also key development directions.

Q4: Why is sustainability important in flexible packaging?

Sustainability must be used to reduce environmental impact and meet consumer and regulatory pressures. Recycling of materials, reduction of waste and emissions (e.g., implementing RTO technology), and reducing the use of non-renewable resources not only help the environment but also establish brand image and reduce long-term costs.

5. How to choose the right custom flexible packaging supplier?

When selecting a supplier, consider their technical capabilities (such as advanced equipment and RTO systems), quality control systems (whether they comply with international standards such as ISO), track record of innovation, environmentally friendly practices, and ability to provide customized solutions. Verifying their industry experience and customer testimonials is also crucial.