The global beverage market is growing, and on top of the standard bottles, the convenience, shipping costs and modern look of flexible drink pouches is drawing more brands to produce them as an alternative. However, not every manufacturer you see online meets international standards.

In this article, you will learn what you will need to evaluate a custom drink pouch manufacturer, which includes certifications, quality systems, approval of samples, MOQ, and production capabilities.

1. Check the Manufacturer’s Qualifications and Certifications

When you find a custom drink pouch manufacturer, the first thing to do is check the company credentials.

Some Credential Certificates to Request

- ISO 9001 – verifies standardized quality management system.

- BRC / HACCP – verifies food-grade production and sanitation.

- FDA / EU – make sure you verify compliance with FDA/EU if the pouches are used for beverages that will be sold internationally.

- Environmental (ISO 14001 or RTO System) – shows environmentally friendly production.

If the custom drink pouch manufacturer is legitimate, they will provide scanned copies or e-verification of these certificates. Do not use a supplier unwilling to show any of these documents; good suppliers should readily share documents outlining credentials.

Tip:

Ask about their factory audit reports or third-party inspection records (such as SGS or TÜV). These reports reveal whether the factory maintains consistent quality control over time.

2. Evaluate Production Capabilities and Equipment

A professional custom drink pouch manufacturer needs to be technically capable of producing various pouch structures such as spout pouches, stand-up pouches, and refill pouches.

What to Verify

- Factory Size: A factory size larger than 10,000 m² typically indicates the ability to produce at mass production levels.

- Production Lines: Verify they have lamination, printing, slitting, and bag making production lines in-house.

- Material Options: Confirm if they have the ability to work with multi-layer films (such as PET/AL/PE and PA/PE) and eco-friendly materials.

- R&D Support: Trustworthy manufacturers provide assistance with structure design and custom printing.

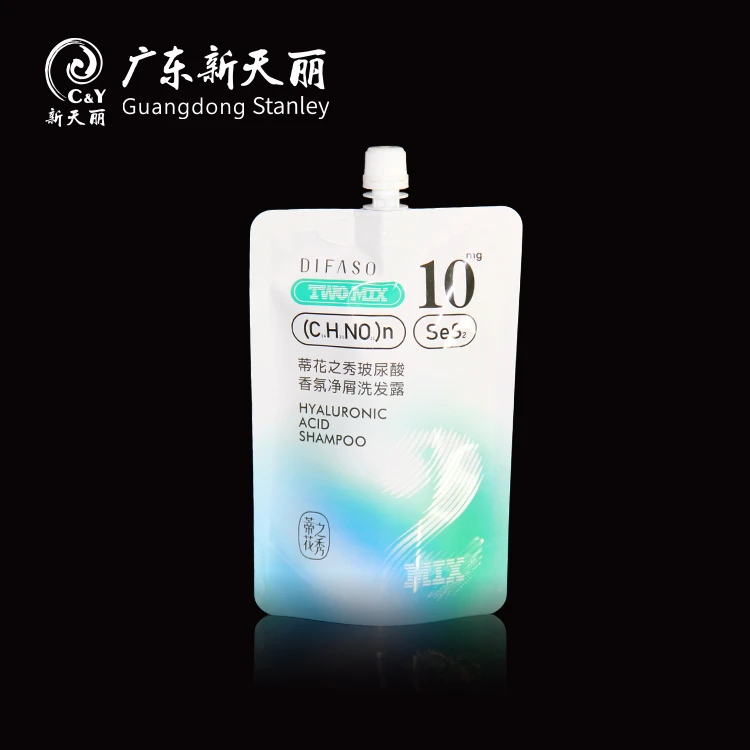

As an example, Stanley Package runs a 15,000 m² modern facility with advanced gravure printing capabilities and a high efficiency RTO system for VOC treatment, ensuring quality product and green production.

3. Assess the Company’s Quality Control System

Robust quality control is essential for any successful packaging project. When selecting your custom drink pouch manufacturer, ensure they have stringent quality control measures in place throughout the various stages of production.

Fundamental QC Procedures

- Incoming Material Inspection: Confirm that the film rolls, inks, and spouts are food-safe and free of defects.

- In-Process Testing: Evaluate the strength of the lamination and the sealing temperature, and confirm print registration.

- Finished Product Testing: Execute leak, drop, and aging tests prior to shipping.

Ask them for their Standard Operating Procedures (SOPs), as well as if they can provide quality reports for each batch. These documents will provide assurance regarding consistency and traceability.

4. Understand Their Sample and Customization Process

It is always advisable to undergo the sample testing phase before placing a significant order. Reputable manufacturers see sampling as a critical step in the process – not simply a formality.

What to Expect:

- Design Confirmation: You share your structure, and artwork requirements.

- Material Recommendation: The manufacturer recommends appropriate film combinations.

- Prototype or Digital Sample: This is typically done within 5-10 working days.

- Functionality Test: Ensure the sealing, spout fit, and print quality.

A trustworthy custom drink pouch manufacturer should communicate clearly at every step and be open to small adjustments before mass production. At Stanley Package, clients can receive free structural design consultation and detailed pre-production samples for approval.

5. Check Minimum Order Quantity (MOQ) and Flexibility

MOQ is an important consideration when it comes to determining the right supplier. Many of the factories in China pose difficult challenges MOQs of 20,000-50,000 pcs per design, which may not work for a small brand or launch of new product.

When selecting your manufacturer, ask:

- What is the MOQ per design or size?

- Do they offer trial orders for new customers?

- Do they have digital printing options for low volume production?

For example, Stanley Package has flexible MOQ options — supersmall pilot production runs, to large production runs for international beverage companies.

6. Evaluate Communication and After-Sales Support

Effective communication and service are also key components to success that are easily overlooked when it comes to international cooperation.

Try to find a supplier that:

- Responds professionally and promptly in English.

- Can provide accurate timelines for project work or sample production, as well as provide update reporting for ongoing projects.

- Can provide after sales support for claims and/or any rework needed.

A good manufacturer wants to build a long-term relationship, not just a one-time business opportunity. The manufacturer should also help you with packaging consultation and modify your pouch structure for better shelf performance.

7. Compare Pricing — But Don’t Chase the Lowest Quote

While it’s true that cost plays an important role in any purchase, it should never be the only consideration. It’s always a good idea to double-check sources of materials and process standards if one supplier’s quote is much lower than others.

A professional custom drink pouch manufacturer will always give you a very organized approach to pricing based on structure of materials, size of pouch, printing options, and order quantities. Respectively, it’s always important to weigh cost, quality, and service stability — that’s what you have come to the best overall value overtime.

Conclusion

Finding a trustworthy custom drink pouch manufacturer is not simply a matter of conducting an online search. Factoring in their past credentials, manufacturing capabilities, quality system, sample process, minimum order quantity policy, and customer service are all critical qualifiers.

A trustworthy manufacturer can not only make custom drink pouches – they become your packaging partner who understands your product, and your brand objectives.

By conducting due diligence in investigating or vetting a manufacturer, you will protect yourself from needless risk and ensure that your food and beverage products are packaged safely, efficiently, and beautifully.

About Stanley Package

Stanley Package was founded in 1998 and is known around the world as a Custom Flexible Packaging Manufacturer specializing in custom tear-top pouches, spout pouches, and roll-stock packaging films. Our facility is located on 15,000 m² and is equipped with advanced production lines and an eco-responsible RTO (Regenerative Thermal Oxidizer) that effectively manages VOC (volatile organic compound) emissions.

With over 25 years of experience, Stanley Package provides complete packaging solutions. We can guide you entirely through this process, including design, lamination, printing, and pouch making. By way of our thorough quality management, we are effectively communicating with you and assisting our global beverage brands in developing a safe, functional, and visually appealing package.