In today’s highly competitive retail landscape, packaging has evolved beyond the role of containers to become a key method of brand communication, user experience, and product protection. A successful pouch packaging design project must not only capture consumers’ eyes but also balance functionality, environmental responsibility, and cost-effective production.

According to statistics, over 72% of consumers say packaging design directly influences their purchasing decisions, and high-performance pouches can increase a product’s shelf appeal by over 50%.

This article systematically explains how to design pouch packaging through a professional process, covering a comprehensive knowledge base from market positioning, structural design, and material selection, providing brands with practical solutions.

Understanding the Product and Market: Pre-Design Strategic Analysis

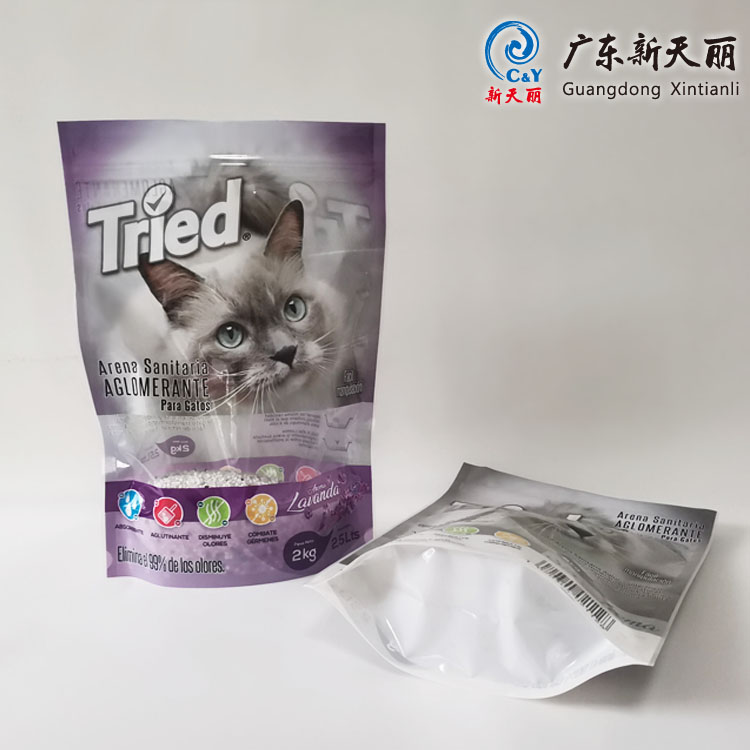

Before pouch packaging design, there should be comprehensive market study and product examination. Different products require different packaging requirements: the food industry requires high-barrier material to prevent oxidation, medical devices require a sterile barrier, while electronics require protection against static electricity. Coffee packaging, for example, typically consists of an aluminum foil laminate structure in order to preserve a 12-month shelf life, while pet food packaging requires tear-resistant reinforcement.

The key activities include:

- First, defining the target consumer segment (consumption pattern, age, and usage context). Kids’ products require safety tear-offs and vivid colors, while premium gifts opt for metallic printing and engaging tactile characteristics.

- Second, studying competing packaging trends. A healthful snack food business saw a 30% increase in repurchase rate after making the switch from typical stand-up pouches to zipper pouches.

- Third, determining distribution channel requirements. E-commerce packaging requires shipping impact resistance, while offline retailers aim for shelf display.

The crux of this stage is to create a list of design pouch packaging needs and set technical parameters such as barrier properties, light transmittance, and puncture resistance.

Structural Design and Functional Innovation: Balancing Form and Practicality

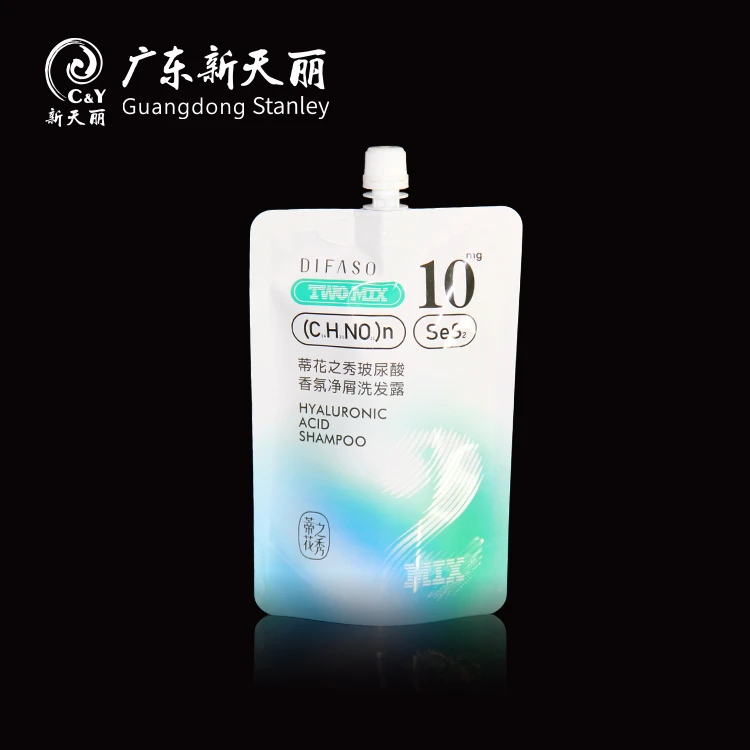

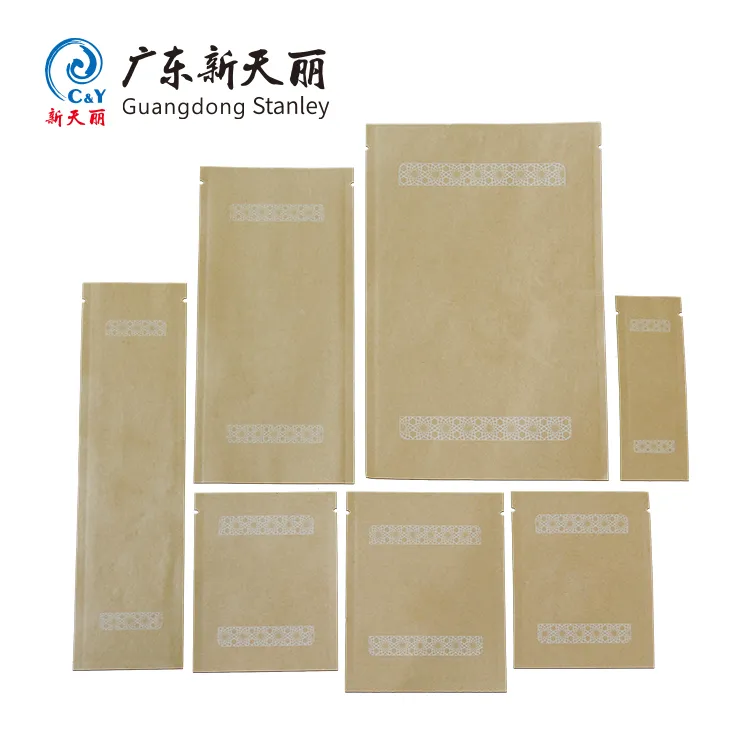

The structural design of packaging bags directly impacts user experience and production efficiency. Common bag types include three-side seal bags, stand-up pouches, spouted stand-up pouches, and roll-to-wrap packaging films. Innovative structures can create significant differentiation. For example, one brand’s resealable zippered stand-up pouch increased its market share by 22%. When designing pouch packaging, considerations include the filling method (vertical automatic filling requires a specific bag shape), opening convenience (easy-tear notch, laser perforation), resealability (zipper, seal), and user experience (smooth pouring).

In terms of technical details, the base structure of the stand-up pouch must maintain a support film thickness of 0.2-0.3mm, and packaging with a spout must ensure that the welds withstand a pressure exceeding 0.4MPa. In recent years, smart packaging has rapidly developed, with innovative features such as integrated QR code traceability systems and temperature-sensitive color-changing inks becoming a trend. It is important to note that structural complexity is directly related to production costs. Each additional feature (such as a hanging hole or a special-shaped cut) reduces bag production efficiency by 15-20%. Therefore, DFM (Design for Manufacturing) optimization is essential when designing pouch packaging.

Material Science and Sustainable Solutions: A Win-Win Choice for Environmental Protection and Performance

Material selection is the core technology of pouch packaging design, directly affecting product protection, printing quality, and environmental performance. Multilayer composite films are the mainstream solution, with typical structures including: PET/AL/PE (high barrier), OPP/VMPET/PE (medium barrier), and single-material PP (recyclable). The combination is selected based on the characteristics of the contents: oily products require an oil-resistant layer, while frozen foods require a tough material with low-temperature resistance down to -40°C.

Sustainability has become an industry focus, with 67% of consumers globally preferring to purchase environmentally friendly packaging. When designing pouch packaging, consider utilizing mono-material structures (such as all-PE stand-up pouches), bio-based films (PLA, PBAT), water-soluble inks, and optimized designs that reduce material usage by 20%. Stanley Package’s RTO exhaust gas treatment system ensures environmental compliance during production, while lightweighting technology can reduce the packaging’s carbon footprint by 35%. It’s important to note that environmentally friendly materials must undergo accelerated testing to verify their performance; for example, compostable packaging must comply with the ASTM D6400 standard.

Visual Communication and Brand Storytelling: The Art of Creating Emotional Connections

Graphic design is the most intuitive consumer touchpoint in designing pouch packaging. An effective visual system should include a high-contrast primary visual area (readable from a distance of 3 meters), precise brand color management (Pantone color deviation ≤ 0.5), regulatory information layout (ingredient list font size ≥ 1.2mm), and tactile design (embossing, spot UV, etc.). Research shows that an excellent color scheme can increase brand recognition by 80%.

Innovations in digital printing technology have opened up new possibilities for design pouch packaging, supporting small-batch customization and variable data printing. Case studies have shown that limited-edition packaging with special effects (hot stamping, embossing) can increase product price premiums by up to 25%. More importantly, packaging should tell a brand story.

For example, one organic brand used a transparent window to showcase product authenticity, which resulted in an 18% increase in conversion rate. Design validation is essential, including focus group testing and shelf simulations to ensure visual appeal under varying lighting conditions.

Regulatory Compliance and Testing and Verification: Key to Mitigating Market Risk

Packaging regulations vary across the globe. When designing pouch packaging, considerations must include compliance with FDA/EC 1935 standards for food contact materials, heavy metal content restrictions (REACH, CP65), labeling regulations (Nutrient Information, Recycling Labels), and Child-Resistant Packaging (CRP) requirements. According to statistics, approximately 23% of product recalls are due to packaging compliance issues.

Rigorous testing is key to ensuring packaging performance, including seal strength testing (≥2.5N/15mm), drop testing (no leakage from a height of 1.2 meters), accelerated aging testing (simulating shelf life in a 40°C/75% RH environment), and transportation testing (ISTA standards). A professional pouch packaging design process should include a Design Failure Mode Analysis (DFMEA) to identify potential risks in advance. Collaborating with an experienced manufacturer is crucial. Stanley Package’s laboratory offers a comprehensive solution, from material coefficient of friction testing to seal integrity verification.

A Holistic Strategy for Successful Packaging Bag Design

Excellent packaging bag design is a systematic process that balances marketing needs, technical feasibility, regulatory requirements, and cost control. From initial strategic analysis to final testing and verification, every step directly impacts market success. Modern design pouch packaging must proactively incorporate sustainable concepts and intelligent technologies to respond to evolving consumer expectations. Brand owners should select partners with comprehensive capabilities to jointly develop packaging solutions that protect the product, enhance the experience, and convey brand value.

By leveraging the five key dimensions outlined in this article—market positioning, structural innovation, material science, visual communication, and compliance testing—companies can establish a scientific design pouch packaging development process. Remember, excellent packaging is more than just a container; it is a silent salesperson, brand ambassador, and product guardian, worthy of the necessary investment of resources and expertise.

About Stanley Package

Stanley Package, a leading global manufacturer of custom flexible packaging, has been dedicated to providing innovative packaging solutions to its customers since its founding in 1998. The company boasts a 15,000-square-meter modern production facility equipped with advanced equipment such as ten-color high-speed printing presses, dry laminators, and fully automatic bag making machines. The company also utilizes an RTO environmentally friendly system to ensure green production. We provide one-stop services from design consultation, material development, to production delivery. Our product offerings cover a wide range of sectors, including food packaging, medical packaging, industrial packaging, and environmentally friendly packaging, helping global clients build a competitive advantage in the market.

Start Your Packaging Innovation Journey Today

Whether you’re at the conceptual stage of packaging design or need to optimize an existing packaging solution, Stanley Package‘s professional team is ready to provide comprehensive technical support. We offer free design consultation and sample creation services to help you quickly verify the feasibility and market potential of your packaging solution.

Please visit our official website for more case studies or email your requirements to our design team. You’ll receive a customized proposal and quote within 24 hours. Let us leverage over 25 years of expertise to create innovative packaging solutions that are both competitive and sustainable.