環境意識の高まりとともに、消費者の間でコーヒーバッグへの期待が変化している。コーヒーに使用されるパッケージは、製品の鮮度や企業の評判に影響するが、それ以上に重要なのは、環境に直接影響を与えるということだ。コーヒー製品のパッケージングを決定する際には、使用する素材に関する情報を十分に得る必要がある。

この記事の中で スタンレー・パッケージ コーヒーバッグの代表的な基材、リサイクルの課題、持続可能な選択肢、今後の方向性などについて議論し、購買担当者が持続可能なパッケージを選択するための実際のアドバイスを得られることを期待している。

一般的なコーヒーバッグの素材

アルミ箔バッグ

アルミ箔のコーヒー袋は、特に高級品種のコーヒーの包装に使用される主要な素材の一つである。これらの袋は湿気、酸化、光などの要因から優れた保護を提供し、それによってコーヒー製品の保存期間の延長に貢献する。とはいえ、アルミ箔袋のリサイクル率は比較的低いままであり、特に専門的なリサイクル・インフラが整っていない地域ではその傾向が顕著である。アルミ箔袋の構造は、一般的にアルミ箔とプラスチックの混合層を含むため、分解が難しく、リサイクル工程を複雑にしている。

ポリ袋(ポリエチレン、ポリプロピレン)

プラスチック袋は、最も安価で広く使用されている包装材料であり、コーヒーのバルク包装や輸出に頻繁に使用されている。ポリエチレン(PE)とポリプロピレン(PP)という2つの最も利用されているプラスチック包装材は、密封性に優れ、耐湿性があるため、短期間の包装に適している。しかし、プラスチック製コーヒーバッグは、リサイクル性において高い課題を抱えている。リサイクルは可能だが、世界のほとんどの地域では、袋を処理する効率的な処理装置がなく、生分解性でないことが長期的な環境への影響に耐える。

紙袋

紙袋は環境面で大きな利点があり、より持続可能な包装オプションを求める消費者を惹きつけている。一般的に紙袋はリサイクル可能であるが、湿気や空気に対する耐性を向上させるために、プラスチックフィルムやコーティングが施されることが多く、リサイクル工程を複雑にしている。さらに、紙袋のバリア機能は比較的限定的であり、長期間の保存においてコーヒーの品質を効果的に維持できない可能性がある。

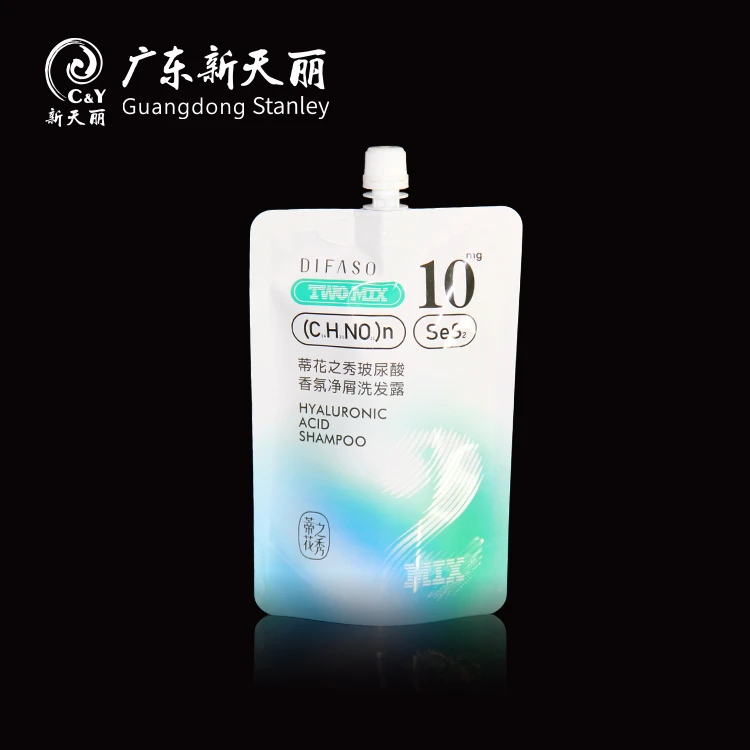

複合袋(紙+アルミ箔+プラスチック)

複合包装は、紙、アルミ箔、プラスチックの各層を混ぜ合わせることで、防湿・遮光性、密閉性を高めたもので、高級品や高品質なコーヒー製品に採用されている。複合素材自体は、多層包装を分解する必要があるためリサイクルが難しく、様々な素材のリサイクルが複雑でコストがかかる。

コーヒーバッグの一般的なアクセサリー

コーヒーバッグに使用される素材に加え、バッグに含まれる成分もまた、パッケージの使いやすさ、利便性、環境への優しさを決定する上で大きく貢献する。以下は、コーヒーバッグに通常付加される様々な付属品の概要である:

ジッパークロージャー

ジッパークロージングはコーヒーバッグに広く使用されており、効率的な開閉手段を提供すると同時に、製品の鮮度を保持します。クロージングは袋の再利用性を高め、エンドユーザーがいつでも中身に何度でもアクセスできるようにし、結果として包装の無駄を省きます。

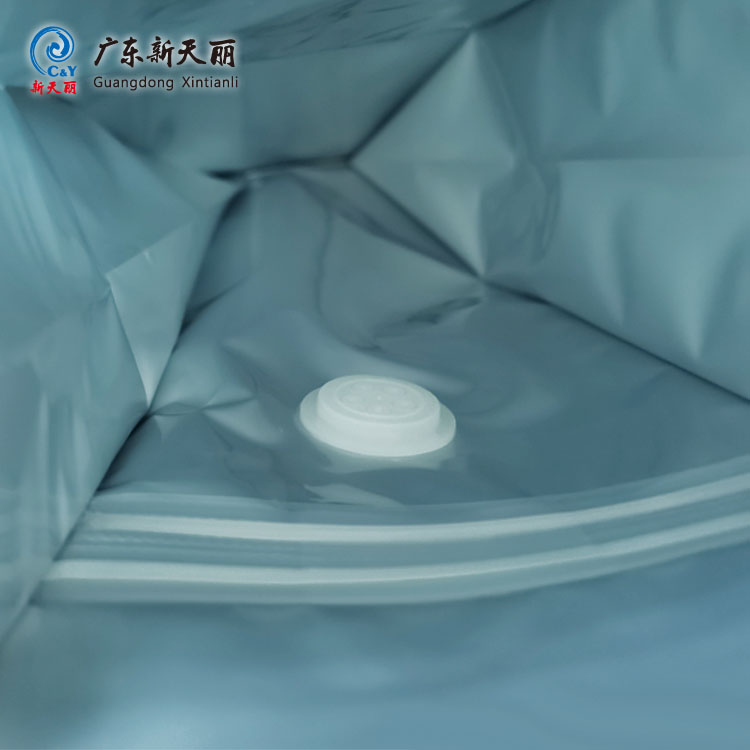

バルブ

バルブはコーヒーバッグに不可欠な機能的アクセサリーで、主にバッグ内に閉じ込められたガス、特にコーヒーの鮮度を保つガスを逃がすために使用されます。このバルブにより、バッグは密閉されたまま内圧を維持し、二酸化炭素などのガスを逃がすことができ、コーヒーの鮮度と風味を長持ちさせることができます。

透明な窓

ある種のコーヒーのパッケージには透明な窓があり、消費者は中に入っているコーヒー豆や挽き粉を 観察することができる。このデザイン要素は製品の魅力を高めるが、透明窓に使用される材料のリサイクル性は、その具体的な組成に左右される。一般的に、透明窓はポリプロピレン(PP)または代替プラスチック材料から製造されるため、リサイクルプロセスが複雑になる。

コーヒーバッグのリサイクル

多層複合材料

多層複合包装袋は、複数の種類の材料で構成されているため、保護性能は高いが、リサイクルには大きな課題がある。複数の素材を分離し、効果的にリサイクルするには、特殊な工場や設備が必要であるが、ほとんどの地方では複合包装材を扱うのに十分な規模がない。

石油とコーヒーかす

コーヒーバッグに含まれるコーヒーかすや油分は、リサイクルの妨げになる。油分はリサイクル材料を汚染するだけでなく、分解プロセスを妨げ、袋を効果的にリサイクルすることを困難にする。そのため、コーヒーバッグはリサイクルする前に徹底的に洗浄する必要があり、消費者とリサイクル業者に高い負担を強いている。

印刷とコーティングの問題

ほとんどのコーヒーパックには、印刷模様やコーティングが施されている。これらのコーティングは危険な化学物質やインクで構成されており、リサイクルプロセスを遅らせる。リサイクル可能な物質の中には、印刷によって汚染され、リサイクルシステムを通過できないものもある。コーヒーの生産者は、包装資材を設計する際に、環境に優しい印刷技術の使用と有害物質の最小限の使用に焦点を当てるべきである。

ジッパーファスナー、バルブ、覗き穴、袋の取っ手などのコーヒーバッグの付属品は、リサイクルの最終段階でより複雑な問題を引き起こす。付属品の多くは、プラスチック、金属、または複合材料で構成されているため、しばしば袋材料からの分離に支障をきたし、従ってリサイクルの道筋にさらなる困難をもたらす。

例えば、こうだ:

- ファスナー開閉式: 多くのコーヒーバッグはプラスチック製のジッパーを使用しているため、さらに分解と加工が必要である。袋の中のプラスチックと他の材料は簡単に分離できないため、完全なリサイクルが不可能になる可能性がある。

- バルブ: バルブは通常、プラスチック、金属、紙などから製造されるため、その多層構造がリサイクル難易度を高めている。このような継手は、効率的に分解して処理するために特別な装置を必要とする。

- C学習 w窓: 透明ベントは通常プラスチックで構成され、紙や他の部品と組み合わされることが多いため、リサイクルが非常に複雑になる。

このような付属品の使用は、コーヒーバッグのリサイクルをより困難にし、より複雑なリサイクルシステムを必要とする。従って、コーヒーメーカーは包装設計の際に付属品のリサイクル性を考慮し、できる限り容易に分解してリサイクルできる付属品や素材を使用すべきである。

地域の違い

リサイクルシステムとインフラの地域差は、さらにコーヒーバッグのリサイクルを混乱させている。地域によってはリサイクルが許可されていない包装材や、リサイクルするために特別な処理機が必要な包装材もある。コーヒー生産者は、地域のリサイクル政策に精通し、可能な限り地域のリサイクルニーズに合った包装材を使用すべきである。

代替品と環境に優しい選択肢

分解可能な材料

バイオテクノロジーの進歩に伴い、PLAのような分解性素材が代替品として市場に参入しつつある。PLA(ポリ乳酸)は植物由来の生分解性プラスチックで、特定の環境条件下で分解する。分解可能な素材を使用することで、プラスチックが環境に与える影響を減らすことができるが、PLA素材の中には、効果的に分解するために工業的な堆肥化が必要なものもあることに留意すべきである。

リサイクル可能な単一素材バッグ

単一素材の袋(紙袋やプラスチック袋など)は、複合素材よりもリサイクルが容易である。リサイクル基準を満たす単一素材を選択することで、コーヒーメーカーは環境への負荷を軽減し、リサイクル率を高めることができる。

インクレスまたは非コーティング包装

インクレスまたはコーティングされていない環境に優しい包装を選択することで、リサイクルの可能性が大幅に高まります。これらの包装には有害な化学物質が含まれておらず、より簡単にリサイクルできる。多くの消費者が有害物質を含まない製品を好むようになり、インクレス包装の人気が高まっています。

リユースバッグ

再利用可能な包装袋も環境に優しい選択肢の一つである。コーヒーメーカーは再利用可能な袋を提供し、消費者に購入後の再利用を促すことができる。これは、包装廃棄物を減らすだけでなく、ブランドと消費者の環境パートナーシップを強化する。

ブランド・リサイクル・プログラム

コーヒーブランドは、回収場所を設けたり、リサイクル団体と提携したりすることで、消費者に使用済みパッケージのリサイクルを促すケースが増えている。これは廃棄物を減らすだけでなく、ブランドのグリーンイメージを高めることにもつながる。

コーヒーバッグの将来動向

継続的な技術の進歩により、コーヒー包装資材の環境性能は徐々に向上していくだろう。将来、コーヒーバッグには、完全な生分解性包装や、廃棄物ゼロの包装デザインを実現する革新的なプロセスなど、より革新的で環境に優しい素材が取り入れられるかもしれない。

同時に、より環境に優しいパッケージングを求める消費者の要望は、より多くの企業が行動を起こし、より環境に優しく持続可能なコーヒーパッケージングソリューションを発売する原動力となるだろう。さらに、世界的な環境規制の強化に伴い、コーヒーメーカーもますます厳しい環境要件に直面することになる。環境に優しい素材やリサイクルの取り組みを採用することは、ブランドにとって競争上の優位性になりつつある。

結論

適切なコーヒーバッグ包装材を選ぶことは、製品の品質や保存に影響を与えるだけでなく、環境や消費者のリサイクル行動にも直接影響を与える。コーヒーメーカーは、環境に優しい素材を選び、包装による環境への影響を減らし、リサイクルや持続可能な取り組みに積極的に参加するよう努力すべきである。革新的なパッケージング・ソリューションと消費者とのエンゲージメントの強化を通じて、コーヒーブランドは激しい競争の市場で際立つことができる。

スタンレーのパッケージプロのコーヒー包装袋メーカー

スタンレー・パッケージ を幅広く提供している。 高品質素材とカスタムデザインのコーヒーバッグ.私たちは、コーヒー業界に持続可能で環境に優しいパッケージングオプションを提供し、ブランド各社が環境要件を満たしながら製品競争力を強化できるよう支援することをお約束します。当社のコーヒーバッグ・パッケージング・ソリューションの詳細や、カスタムメイドのお見積もりについては、お気軽にお問い合わせください。