今日の軟包装業界では、印刷技術は包装の外観品質に関連するだけでなく、ブランドイメージ、生産効率、コスト管理、市場のリズムにも直接影響する。カスタマイズ、小ロット、多品種といった市場の要求が高まる中、企業は印刷方式を選択する際、グラビア印刷とデジタル印刷のどちらを選ぶかを天秤にかけるようになってきている。

では、この2つの印刷方法にはどのような違いがあるのでしょうか?あなたの製品に最適なソリューションはどのように選べばいいのでしょうか?この記事で詳しくお答えします。

グラビア印刷とデジタル印刷とは?

グラビア印刷

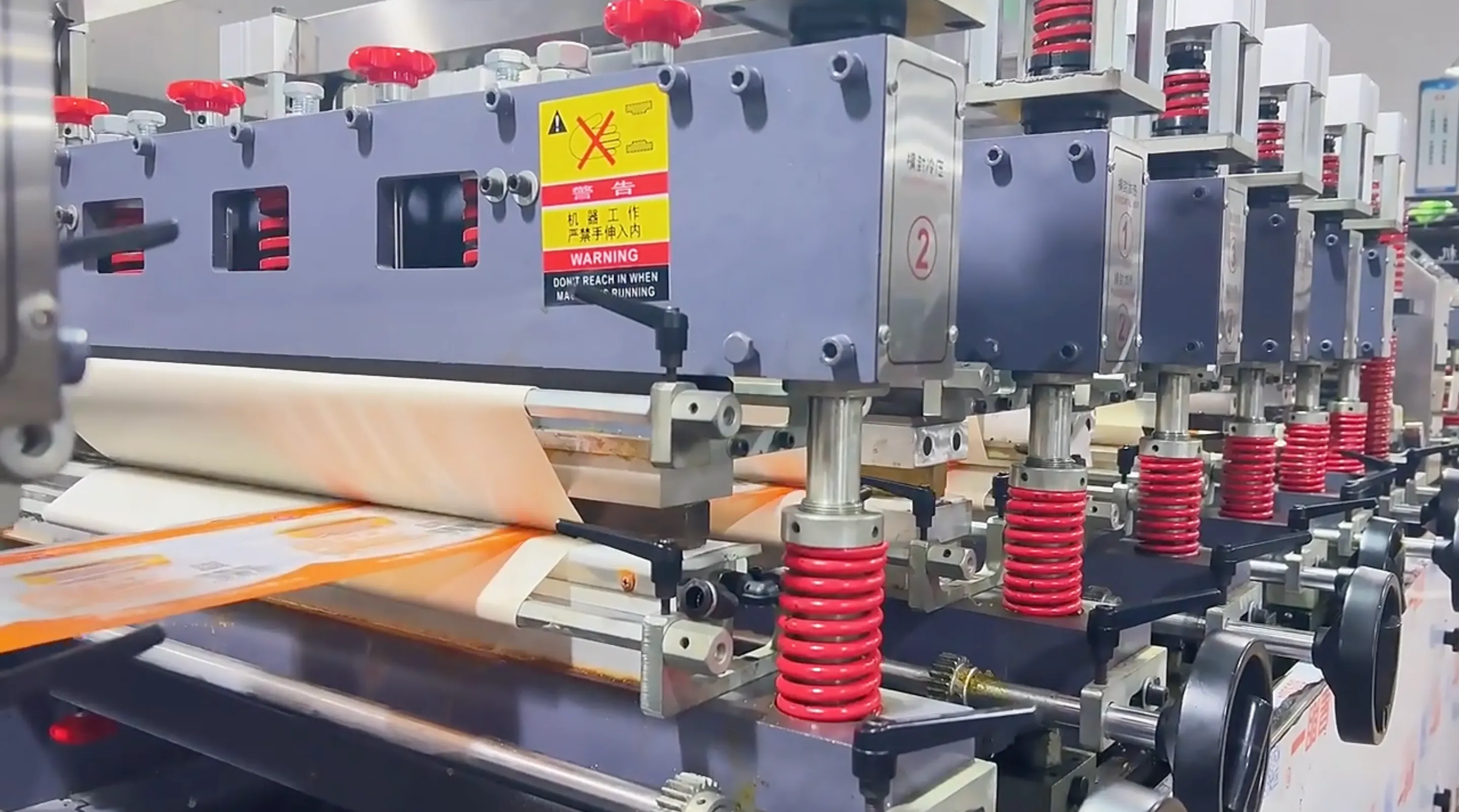

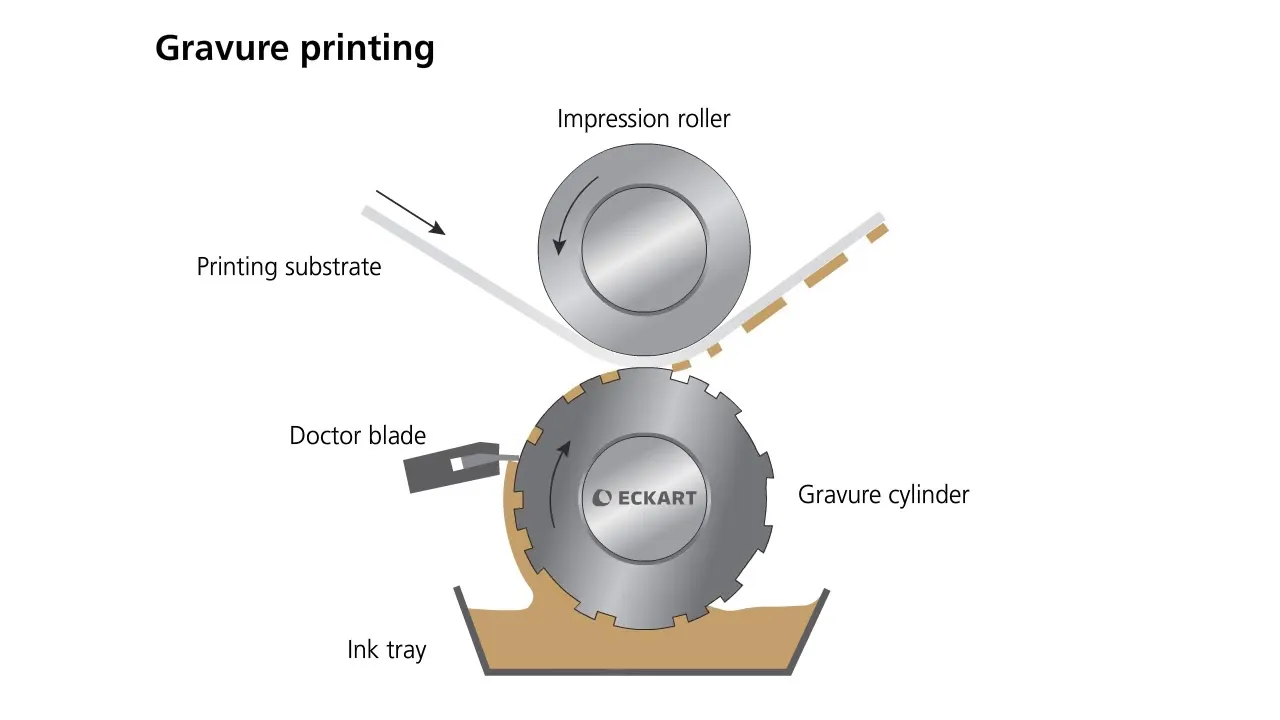

グラビア印刷は、伝統的で効率的な成熟した印刷方法である。金属ローラーにグラフィック溝を彫り、その溝を使ってインクを運び、高圧で包装フィルム素材の表面にインクを転写する。鮮明な画像と安定した色彩のため、大規模印刷において非常に高い費用対効果を発揮する。

テクニカル fが特徴だ:

- 事前の製版(銅版彫刻)が必要

- 印刷速度が速く、長時間の大量注文に適している。

- フルカラー、強い柄のレイヤリング

- 同一バッチの製品の高い色の一貫性

デジタル印刷

デジタル印刷は、デジタルファイルに基づいてフィルム素材の表面に画像を直接印刷する最新の印刷技術です。従来の製版工程が不要で、デザインの変更がより柔軟になり、生産サイクルが短いため、特にパーソナライズされ、変化するニーズに適しています。

技術的な特徴

- 製版不要のダイレクトファイル印刷

- 小ロットでの効率的な生産

- 可変データ(QRコード、バッチ番号など)の印刷が可能

- 迅速な対応と市場の変化への強力な適応能力

グラビア印刷とデジタル印刷:包括的な比較

| 項目 | グラビア印刷 | デジタル印刷 |

| 原則 | 彫刻シリンダーを使用してインクを素材に転写する。 | インクジェット技術でパターンを直接プリント |

| 製版 | 彫刻が施された銅板が必要 | 版不要、デジタルファイルから直接プリント |

| MOQ | 最低注文数量が高く、大量ロットに適している | 小ロットのカスタマイズに対応し、柔軟性が高い |

| コスト構造 | 初期めっきコストは高いが、大量生産時の単価は低い | プレート代がかからず、小ロットでは経済的 |

| カラーパフォーマンス | 安定した豊かな発色で、高精度なデザインに最適 | 鮮やかな色彩で、短期製品や動きの速い製品に適している。 |

| リードタイム | 製版+印刷、納期が長くなる | 高速印刷、リードタイム短縮 |

さまざまなシナリオでどう選ぶべきか?

グラビア印刷を選択する理想的なシナリオ

- 大量・長期使用向け主要製品パッケージ

- 画質と色再現に対する要求が極めて高い

- 単価がより競争的になることを望む

- 準備期間が長く、製版時間を許容できる

代表的な応用産業

- 主な食品包装(スナック、飲料、シリアル)

- 日用化学製品(洗濯洗剤、シャンプー、洗剤)

- ペットフード(ドッグフードやキャットフードなどの大容量パック)

- 農産物(米、種子、肥料包装)

デジタル印刷を選択する理想的なシナリオ

- 小ロット、複数SKU、季節商品

- 迅速な市場需要、短納期

- パーソナライズされた、またはハイエンドのカスタマイズされたパッケージング

- QRコード、トラッキングコード、可変情報を使ったデザイン

代表的な応用産業

- 健康食品/栄養補助食品(トライアルパック、コンビネーションパック)

- ブティック・コーヒーと紅茶のパッケージ

- 越境ECやDTCブランド向けの迅速なサンプル制作

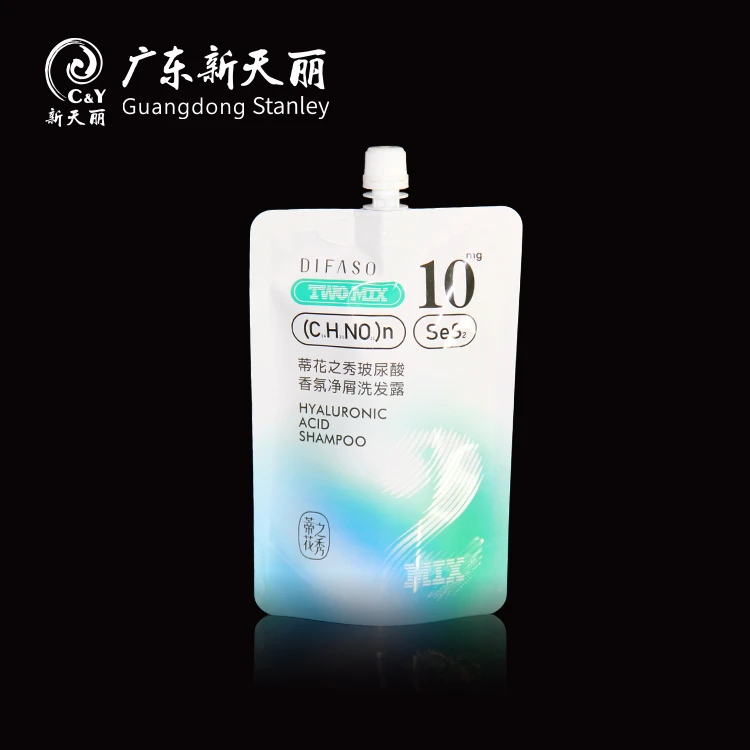

- 化粧品のトライアルパック、ホリデーギフト用の限定パッケージ

- ポップアップ/ジョイント/フェスティバル・マーケティング・イベントのパッケージング

市場動向:デジタル印刷は急成長しているが、グラビア印刷が依然として主流

近年、柔軟なデジタル印刷技術の成熟に伴い、デジタル印刷は、迅速な対応と小ロットのカスタマイズの分野でその優位性がますます顕著になってきており、特に中小ブランド、新しい消費者ブランド、国境を越えた電子商取引の顧客に人気がある。

しかし、特に食品、農業、日用化学品など、単価、生産能力、色精度に高い要求がある業界では、グラビア印刷は依然として世界的に主流の産業用印刷方法である。その優位性は短期的に完全に取って代わることはできない。

したがって、ハイブリッド印刷戦略は、より多くのブランドや工場が選択するようになってきている。メインSKUとしてグラビアを使用し、限定版や新製品の試験販売にデジタルを使用する。

スタンレー・パッケージ製品に最適な印刷ソリューションの構築

として プロのフレキシブル包装メーカー, スタンレー・パッケージ は完全なグラビア印刷とデジタル印刷の生産ラインを持っています。高品質な包装袋の生産サービスを提供するだけでなく、お客様のニーズに応じて、次のようなサービスも提供しています:

- OEM/ODMのカスタマイズされた設計

- 包装材料構造と印刷方法の提案

- 無料校正と迅速なサンプル納品サービス

- バリアブルデータおよび偽造防止印刷ソリューション

- 環境に優しいインクと材料オプションのサポート

私たちは、様々な業界を含む卸売包装袋のカスタマイズサービスを提供しています:

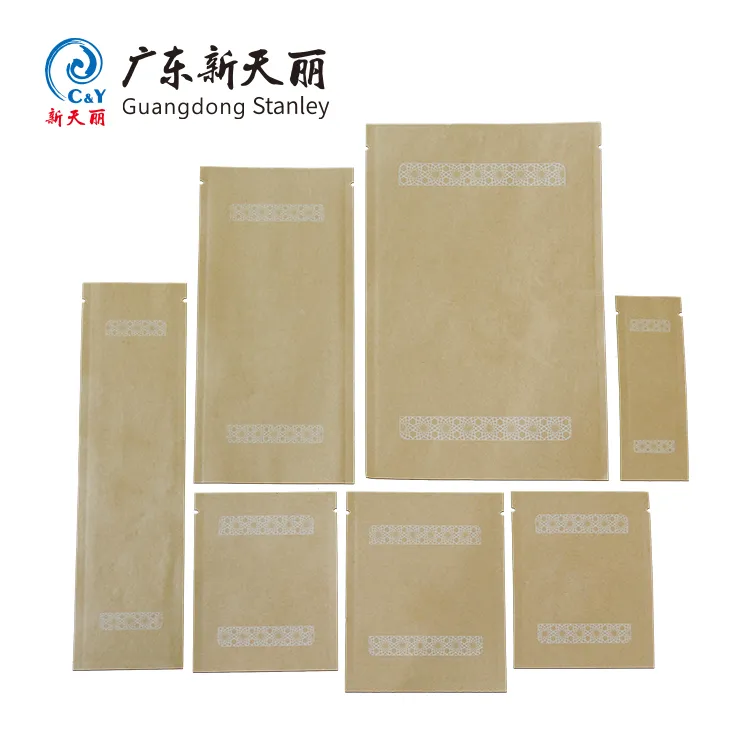

- 食品用ジッパー袋、八方シール袋、平底袋

- 医療用ソフトバッグ、小容量アルミ箔バッグ

- コーヒー包装袋、冷凍食品袋、ペットフード袋

- 化粧品パッケージと販促用バッグ

- パーソナライズされたデザインとバリアブルデータ印刷サービス

どの印刷方法を選択するかまだ躊躇していますか?ようこそ スタンレー・パッケージ 専門的なアドバイスと無料サンプルのために。適切なパッケージング・ソリューションで製品の競争力を高めるお手伝いをさせてください!