今日のスナック菓子市場において、包装はもはやキャンディーを保護するだけの容器ではなく、ブランドのプレゼンテーションに欠かせないものとなっています。スタンレーパッケージは中国の大手包装メーカーとして、顧客志向のアプローチをとり、ブランドのために高品質でオーダーメイドのグミキャンディ包装ソリューションを提供することに尽力しています。この記事では、グミキャンディーのパッケージデザイン事例を取り上げ、私たちがどのように顧客のニーズに基づいて完璧な製品を提供しているかを紹介します。

クライアントの要求ブランドの個性とキャンディの特徴を強調する

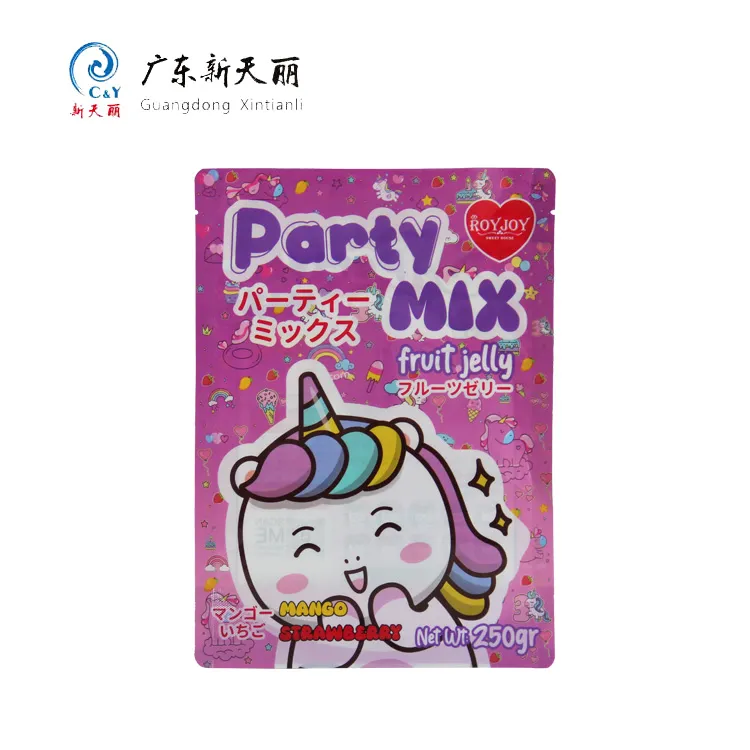

私たちのクライアントは有名なグミキャンディブランドです。グミキャンディの新商品を、斬新で個性的なパッケージデザインでアピールしたいとのことでした。彼らのニーズは単純明快で、グミキャンディの鮮やかな色彩を表現でき、密封性の高いグミキャンディのパッケージパウチであること。さらに、開封しやすく、ブランドのメッセージを効果的に伝えられるパッケージであること。

デザインコンセプト:ビジュアルとユーザビリティの完璧な融合

このグミ・キャンディのパッケージを作るにあたり、私たちはまず次のような重要な要素を特定した:

ハイライト Cアンディーズ Cオロールと Fオーム グミキャンディはもともと色鮮やかで、形もさまざまなため、透明な窓がデザインのポイントになった。透明な窓を通して、消費者は袋の中のキャンディーの色や形をはっきりと見ることができ、購買意欲を高めることができる。

便利な開店体験: 消費者の利便性を高めるため、ティアノッチ・デザインを採用し、工具を使わずに簡単に袋を開けられるようにしました。このデザインは、消費者の利便性を高めるだけでなく、キャンディーを外部の汚染物質から保護します。

ブランド・ディスプレイと情報配信: 両面印刷デザインのグミ・キャンディ・パッケージは、袋の両面にブランド情報、製品の特徴、マーケティング・コンテンツを表示することができます。この印刷ソリューションは最大10色まで対応しており、鮮やかで人目を引くパッケージを実現します。

製造プロセス:設計から生産までの精密な実行

PETの高い透明性とPEの優れた密封性を併せ持つPET12/PE95素材を使用しています。この素材は袋の丈夫さを保証するだけでなく、空気や湿気を効果的に遮断し、グミキャンディの鮮度を保ちます。

トップ・フィリングのデザイン: このデザインは生産効率を高めると同時に、キャンディの損傷を防ぎ、各グミキャンディの完全性を保証します。両面印刷:ブランドの視認性を最大限に高めるため、両面印刷により、このグミ・キャンディ・パッケージの両面に鮮明な画像とテキストが表示され、ブランドの視認性が高まります。

耐久性と美学: 長持ちする素材と最新の印刷技術を選び、輸送や流通の間中、すべてのグミ・キャンディのパッケージが高級感を保ち、耐久性と破れにくさを提供できるようにしました。

最終結果ブランド反映の成功

入念なデザインと効果的な生産により、このグミ・キャンディ・パッケージは、キャンディ・ブランドの鮮やかな色彩を効果的に表現しながら、非常に機能的です。透明な窓はキャンディの色が見えるようにし、簡単に引き裂けるノッチ機能は消費者の開封体験をさらに高めます。両面印刷は、ブランドのメッセージを広範囲に伝え、競争の激しい市場において、ブランドの認知度を高めます。

一般的なグミキャンディのパッケージデザイン

上記のカスタムデザインとは別に、市場で入手可能な標準的なグミキャンディのパッケージデザインには、次のような数多くの汎用性の高いオプションがあります:

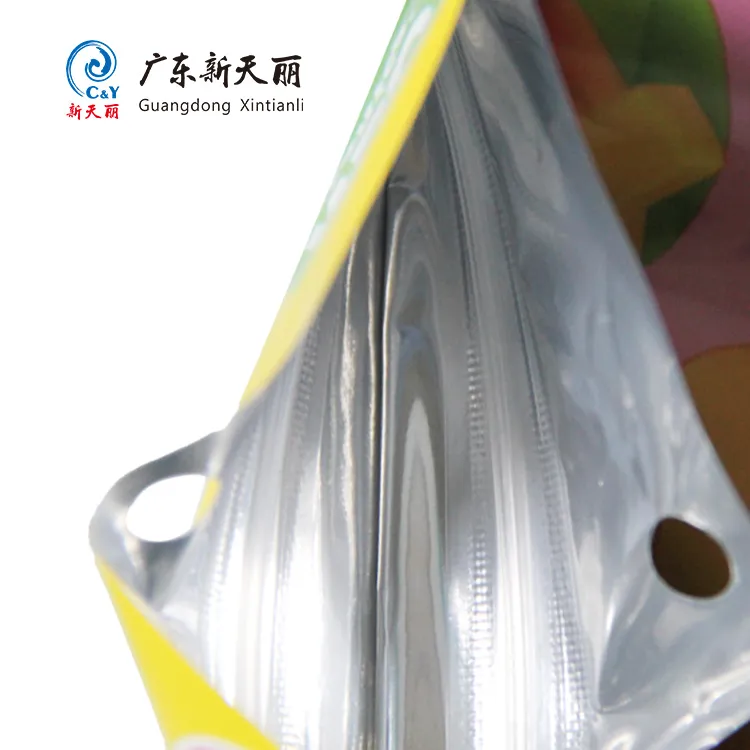

ジッパーデザイン

ジッパーバッグも人気のデザインだ。袋の密封性を高めるだけでなく、何度開封しても消費者がキャンディーを新鮮に保つことができる。ジッパーデザインは、特にファミリーサイズや大きなパッケージに適している。

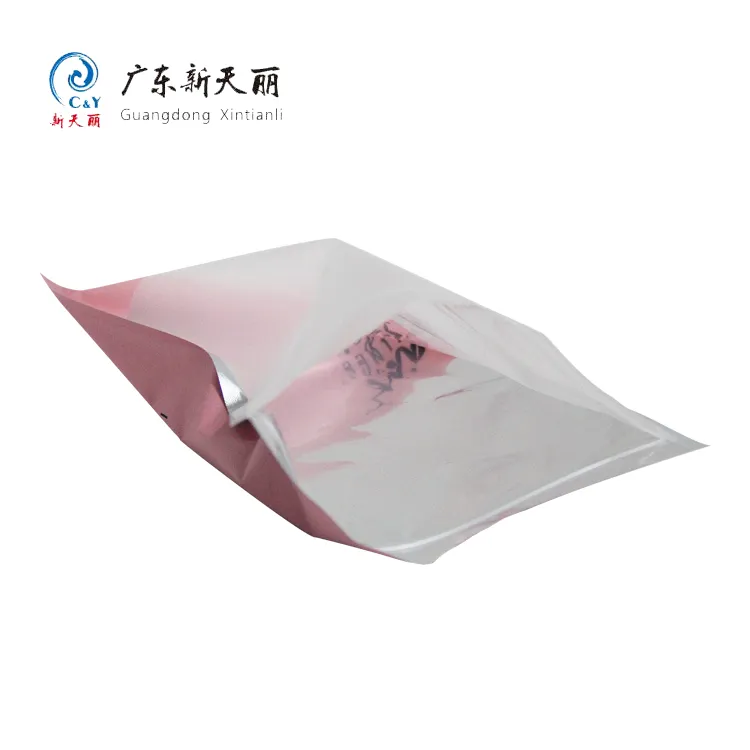

特殊形状デザイン

特殊な形状のパッケージをカスタマイズすることで、製品を市場で目立たせることができる。例えば、ユニークな袋の形や目立つクロージャーを使い、ユニークなブランドイメージを作り出しているブランドもある。このデザインオプションは、消費者の関心を高め、ブランドの印象を深めるのに役立つ。

透明な窓

この事例のように、透明な窓のデザインによって、消費者はキャンディの色や形を直接見ることができる。透明窓の大きさや形は、キャンディの特徴に合わせて柔軟に調整できる。

各種ポーチサイズ

カスタマイズされたパウチのサイズは、ターゲット市場や販売チャネルによって異なります。持ち運びに便利な小型の袋から、家族で持ち運べる大型の袋まで、お客様のご要望に合ったサイズと容量設計でご提供いたします。

グミキャンディのパッケージをカスタマイズする際の考慮点

グミキャンディのパッケージをカスタマイズする場合、以下の点を特に考慮する必要がある:

素材の選択

グミキャンディの包装材料は、キャンディが長期間の輸送や保管中も新鮮さを保てるよう、優れた耐湿性と酸化防止特性を備えていなければならない。一般的な材料には、PET、PE、アルミ箔複合材などがあり、それぞれ異なる機能特性を有しています。

デザインと印刷

グミキャンディーの包装用フィルム素材には、長時間の輸送や保管でもキャンディーの鮮度を保つために、優れた耐湿性と酸化防止機能が要求される。PET、PE、アルミ箔などの複合材料が一般的で、それぞれ様々な機能性を持っています。

生産リードタイムと納期

グミキャンディーの包装袋をカスタマイズする場合は、製品発売の遅れを避けるために、生産リードタイムと納期を事前に計画することをお勧めします。通常、カスタム生産の最小注文数量は50,000個で、生産リードタイムは注文サイズと複雑さによって異なる場合があります。

機能性と美しさのバランス

パッケージは美的な美しさだけでなく、実用的でなければならない。例えば、開けやすさ、耐湿性、密閉性の高さなどは、消費者が購入する際に重要視する点である。

カスタムグミキャンディ包装プロジェクトの開始

あなたのグミ・キャンディ・ブランドのために特徴的なパッケージをデザインする用意があるなら、 スタンレー・パッケージ はあなたの信頼できるフレキシブル包装メーカーです。プロのデザインチームと高度な生産設備で、お客様のニーズに合わせたカスタムグミキャンディ包装ソリューションを提供いたします。

あなたのユニークなグミキャンディパッケージのカスタマイズを開始し、あなたのブランドが市場で目立つようにするために、今すぐお問い合わせください!