Explore how mono-material flexible packaging is leading a green revolution in the packaging industry. This article will delve into the environmental advantages, technological breakthroughs, and key role of single-material packaging in enhancing a brand’s sustainability image, helping you gain a competitive edge in the era of plastic reduction.

What is Mono-material Flexible Packaging?

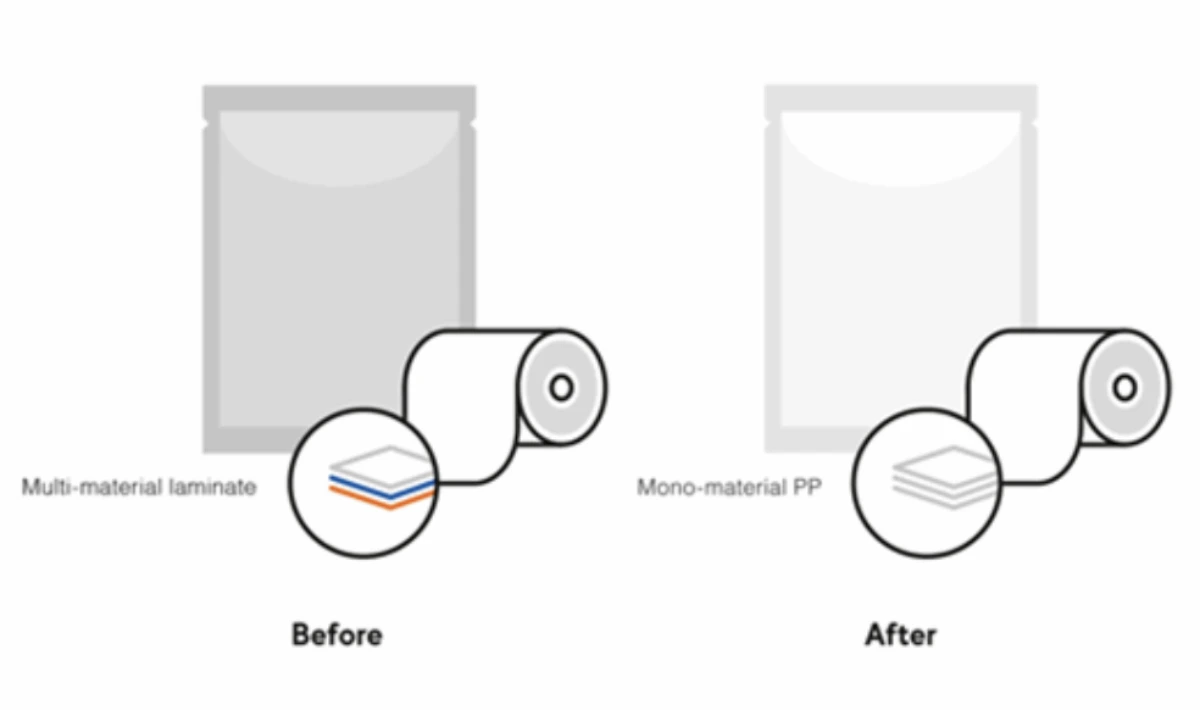

Many traditional packagers created packaging bags using combinations of numerous layers of different materials (e.g., PET, aluminum foil, and PE) for structural strength and barrier performance. A combination of multiple layers of material gives rise to a heterogeneous structure making recycling extremely difficult. Mono-material flexible packaging offers a completely different take on the packaging industry compared to how packaging was created for many years.

Definition and Core Logic

Flexible mono-material packaging is a packaging material that consists only of a single polymer (e.g., 100% PE, 100% PP & etc.), allowing it to be fully recyclable without the potential for contamination from other materials or mixing them together, which would limit the recyclability of a package. This allows for flexible mono-material to be recycled into many different products, increasing the capability for sustainability and the ability to effectively reuse resources.

Why Choose Mono-material Flexible Packaging?

Due to the growing stringency of global regulatory schemes regarding the environment, along with heightened public consciousness regarding our planet’s health, mono-material flexible packaging is being seen as unavoidable due to brand transition to modern environmentally viable options.

1. Superior Recyclability

The term “Mono-material Flexible Packaging” refers to the closed-loop recycling program offered by manufacturers compared to the multi-layer composites of pouches that cannot be recycled back into like-product configurations and only have the ability to be ground and manufactured into another product after they are disposed of. Therefore meeting the definition of circular economy.

2. Excellent Barrier Properties

Previously, the idea that one type of material could accomplish preservation was troublesome for many individuals. Today’s mono-material flexible packaging is now capable of providing comparable levels of moisture and oxygen barrier performance to that of traditional multi-layered products through advancements in coating technology and process development.

3. Enhanced Brand Reputation

Combining the “100% Recyclable” label with the adoption of “Mono-Material Flexible Packaging,” strengthens consumer brand trust while supporting company’s ESG (Environmental, Social and Governance) commitments.

Technological Breakthroughs and Application Scenarios

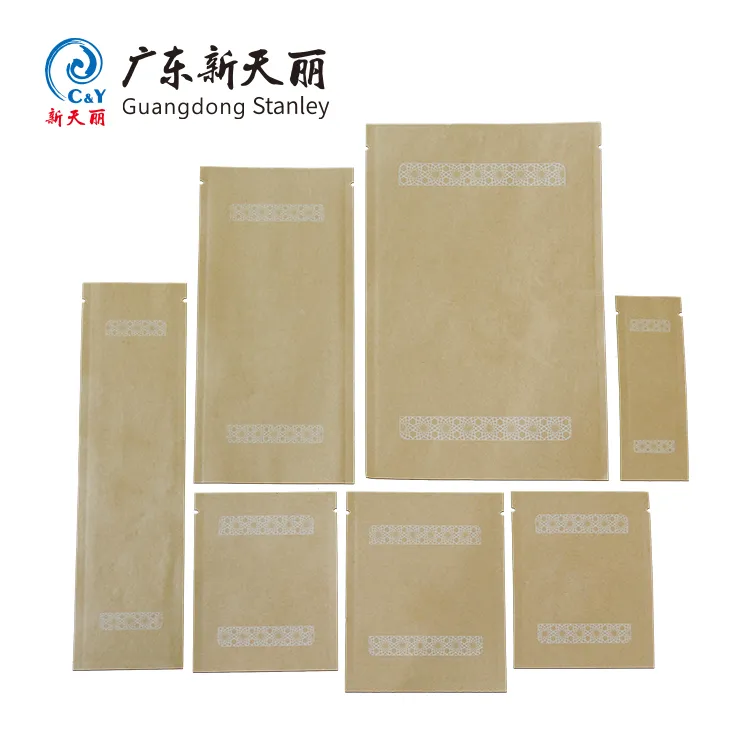

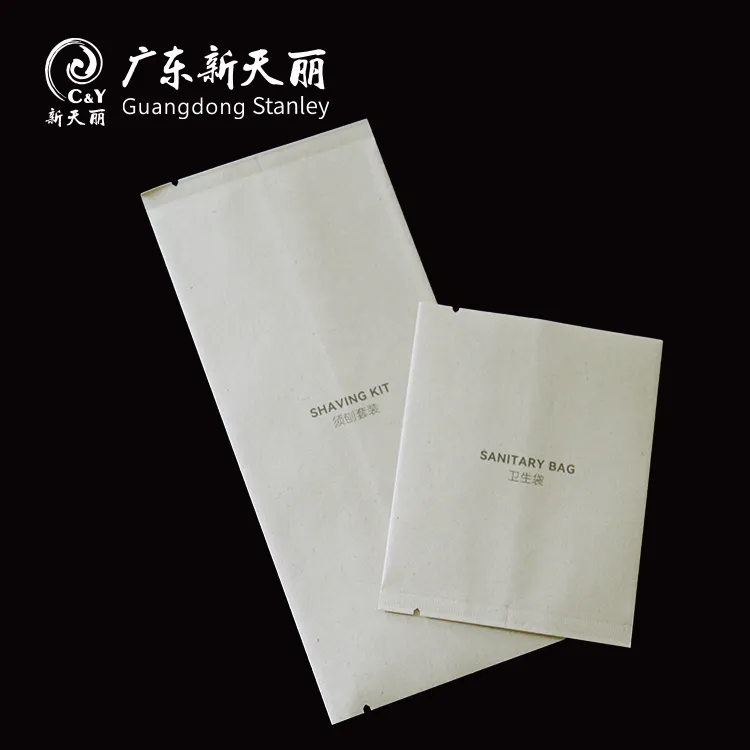

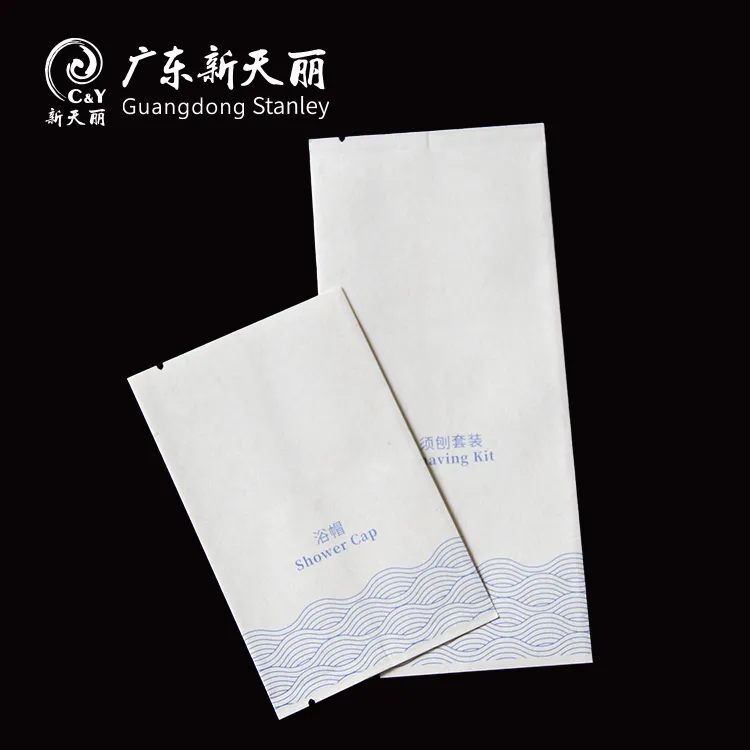

Stanley Package‘s mono-material flexible packaging has been widely applied across multiple industries:

Food and Snacks

From coffee beans to frozen foods, our mono-material flexible packaging can withstand extreme temperature changes while locking in aroma, ensuring food safety and taste.

Daily Chemicals and Personal Care

Laundry detergent refills or face mask pouches can now also utilize mono-material flexible packaging, maintaining packaging rigidity while reducing carbon footprint.

Why Choose Stanley Package as Your Partner?

As a Custom Flexible Packaging Manufacturer founded in 1998, Stanley Package has always been at the forefront of packaging technology. We deeply understand the importance of mono-material flexible packaging for modern businesses; therefore, in our 15,000 square meter modern factory, we have invested in state-of-the-art production equipment to precisely control the lamination and printing processes of single materials.

We not only focus on the environmental friendliness of the products themselves, but also on the greening of the production process. Stanley Package employs a highly efficient RTO system to manage VOC emissions, ensuring that every mono-material flexible packaging is produced in a low-carbon, environmentally friendly environment.

Start your green packaging transformation journey

Whether you’re looking for high-performance flexible pouches, or roll stock packaging film, Stanley Package has a number of packaging options available to you that are based on the most recent trends in your respective market. For help designing and manufacturing a sustainable future, contact our knowledgeable team.