Stanley Package is focused on advancing sustainability in our industry. With our Mono-Material Spout Pouch, we bring you the new generation of green innovation after launching this product into the liquid soap market. The pouch is made of one single material while still providing packaging protection for your product and also being recyclable and environmentally sustainable, making it easier for brands and consumers. No more complicated multi-layer films; it is now easy, simple, and sustainable packaging!

The New Trend in Liquid Soap Packaging: Embracing a Sustainable Future

With increasing global awareness regarding environmental sustainability, consumer demand for sustainable options is also sharply increasing. For Fast-Moving Consumer Goods (FMCG), such as liquid soap, the sustainability of its packaging is becoming even more important for brands. Stanley Package, as a Custom Flexible Packaging Manufacturer, is poised to lead the charge through our cutting-edge production equipment and quality management.

What is a Mono-Material Spout Pouch?

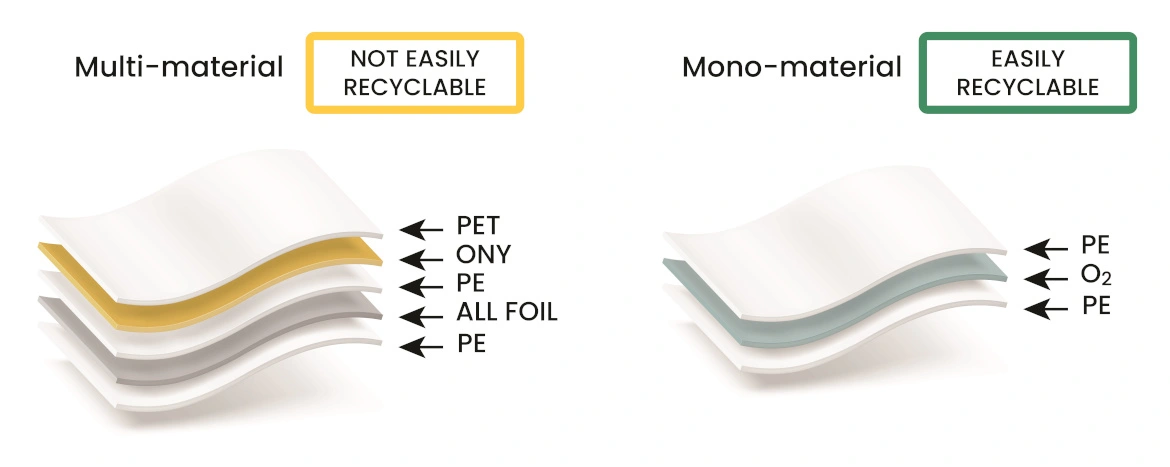

A Mono-Material Spout Pouch is exactly what it sounds like; a soft packaging bag with a spout (or “nozzle”) sourced from a single type of polymer material. By contrast, a traditional multi-layer package (often made of different plastics or foil layers that are often difficult or impossible to recycle) has a single material construction which simplifies recycling and allows for easy blending into plastic recycling streams in the existing recycling system.

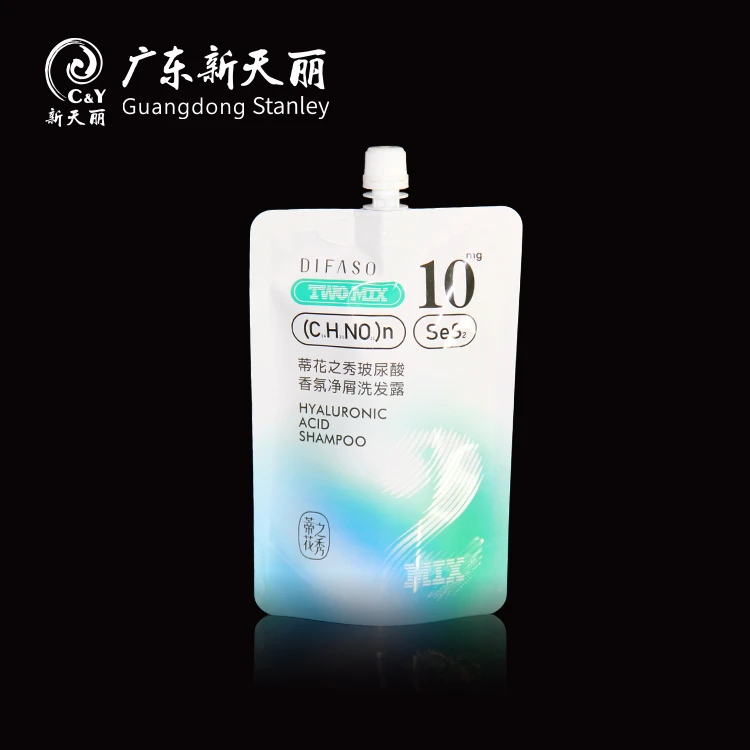

The Mono-Material Spout Pouch provided by Stanley Package is specifically engineered for filling and refilling liquid products, making it ideal for products such as hand soap and shower gels.

Environmental Advantages and Innovation of the Mono-Material Spout Pouch

We continuously implement the “Green Production” philosophy in our company, from our operational procedures to the implementation of an effective, environmentally friendly RTO system to control VOCs emissions. This commitment towards sustainability is evident in our product innovation capabilities, especially through the development and promotion of Mono-Material Spout Pouch.

Structured Content: Environmental Benefits at a Glance

| Benefit Category | Mono-Material Spout Pouch Advantage | Why is This Important? |

|---|---|---|

| Recyclability | 100% recyclable, meeting standards for most recycling facilities. | Solves the recycling challenge of traditional multi-layer pouches, significantly boosting plastic recovery rates. |

| Carbon Footprint | Lower energy consumption during production and transportation compared to glass or rigid plastic bottles. | Reduces energy usage and lowers the brand’s total carbon emissions. |

| Resource Efficiency | Requires less material volume than rigid plastic bottles. | Conserves valuable virgin resources, aligning with circular economy principles. |

| Logistics | Lightweight and flat design enhances shipping efficiency (especially for empty pouches). | Reduces logistics costs and fuel consumption. |

A study on packaging sustainability demonstrated that depending on the application, shifting from rigid plastic bottles to flexible packages, like the Mono-Material Spout Pouch, can drive a 70% reduction in plastic usage and a 50% reduction in greenhouse gas emissions. This data provides strong evidence of the incredible potential of flexible packaging systems, including the recyclable Mono-Material Spout Pouch, to deliver environmental benefits.

Brand Upgrade: Pros and Cons of the Mono-Material Spout Pouch

For liquid soap brands considering a packaging transition, here are the Pros and Cons of the Mono-Material Spout Pouch you need to know:

| Pros | Cons |

|---|---|

| Environmental Recyclability: Simplifies the recycling process, meeting the demands of sustainability-conscious consumers. | Product Protection: May require more sophisticated film design to match the barrier properties and shelf life of traditional multi-layer materials. |

| Enhanced Brand Image: Clearly communicates the brand’s environmental commitment, fostering consumer loyalty. | Lack of Rigidity: As flexible packaging, it might require additional external support during filling and shelf display. |

| Cost Efficiency: Reduced raw material use and lower shipping weight help decrease overall costs. | Filling Compatibility: Switching to pouch packaging may require adjustments or upgrades to existing filling equipment. |

| Functionality: Spout design is convenient for pouring and refilling, offering a good user experience. |

FAQs About Stanley Package’s Mono-Material Spout Pouch

Q: Is the Mono-Material Spout Pouch suitable for my liquid soap product?

A: The vast majority of liquid soap products are highly suitable. The Mono-Material Spout Pouch offers great sealing and chemical resistance that protects the product well. Stanley Package has expertise to offer to customize the film structure for your product’s unique features (pH, viscosity, etc.) to ensure compatibility and shelf-life.

Q: How does Stanley Package ensure the quality of the Mono-Material Spout Pouch?

A: Stanley Package operates from a 15,000 square foot modern facility equipped with the latest production machinery. We strictly comply with an excellent quality management system assuring every Mono-Material Spout Pouch retains food-contact grade (where applicable) and assures high physical performance, to prevent leaking.

Q: How do I get started with using the Mono-Material Spout Pouch for my products?

A: The process is straightforward! Simply contact Stanley Package‘s sales team and share your product requirements and design ideas. We will provide a one-stop customized service covering material selection, structural design, graphic printing, and final production.

Outstanding Flexible Packaging Company Since 1998

Stanley, a market-leading flexible packaging company, was founded in 1998 and currently has a plant area of more than 8,500 square meters and a building area of more than 15,000 square meters. Our flexible packaging factory has domestic advanced automated packaging production lines and professional quality testing laboratories.