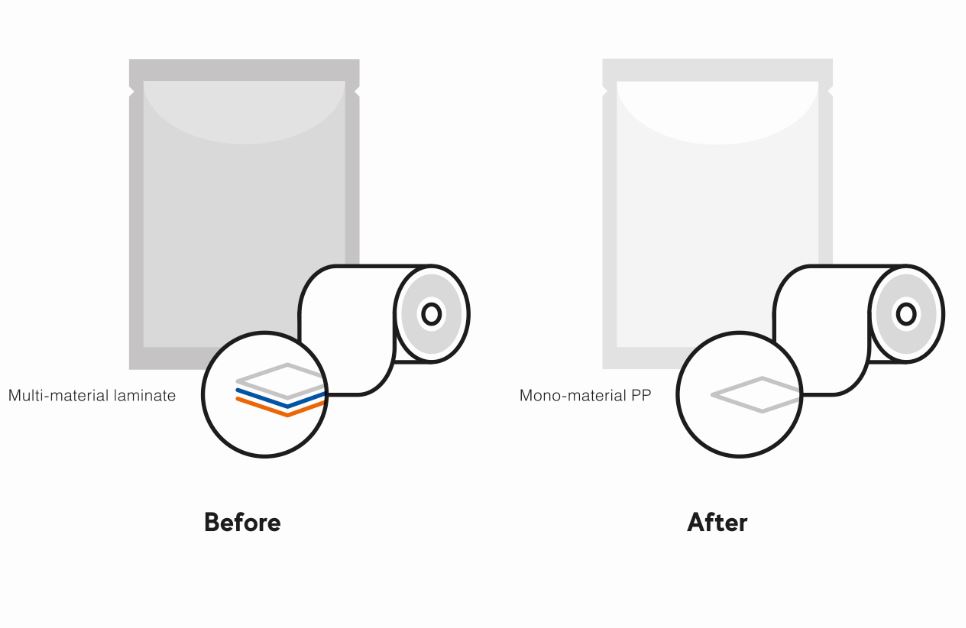

With the increasing environmental awareness and consumer demand for sustainable products, the packaging industry is rapidly turning to more environmentally friendly options. Mono-Materials packaging, as an innovative solution, is becoming the future trend of sustainable packaging. By using a single material, packaging design can not only improve recycling efficiency, but also reduce the generation of plastic waste, thus achieving greener product packaging.

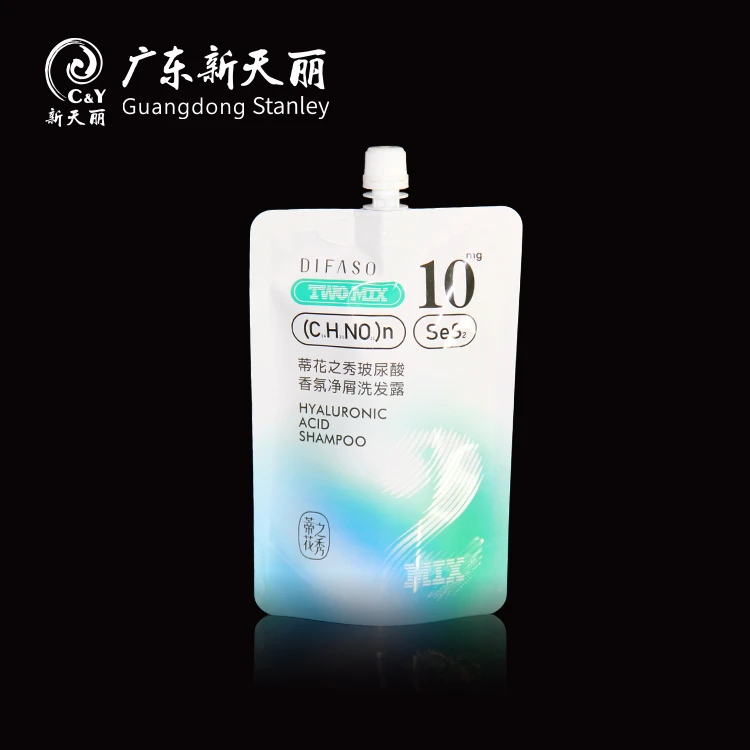

As a leading flexible packaging pouch manufacturer, Stanley Package is committed to providing a variety of sustainable packaging solutions. We focus on using mono-materials to help companies achieve environmental goals and improve the functionality and aesthetics of packaging through innovative designs. Today, we will discuss some widely used mono-materials that are playing an increasingly important role in sustainable packaging.

Polyethylene (PE)

One of the most commonly used mono-materials is Polyethylene (PE), and it is used extensively in the packaging of food, daily products and personal care products. Due to its light weight, durability and good moisture resistance, PE packaging can not only has the function of effectively protecting products from the external environment, but is also used effectively during recycling.

Advantages:

- Good waterproof and UV resistance.

- Easy to recycle, especially in single-material packaging, with high recycling efficiency.

- Lightweight, reducing transportation costs and carbon emissions.

Polypropylene (PP)

Polypropylene (PP) is another common mono-material, which is used in many flexible packaging solutions, including snacks, candies and daily consumer goods packaging. The biggest feature of PP is its resistance to high temperature and chemical corrosion, which is particularly suitable for food packaging that requires heating and high-temperature treatment.

Advantages:

- High heat resistance and chemical corrosion resistance.

- Suitable for food packaging, and will not release harmful substances at high temperatures.

- Relatively easy to recycle and reuse.

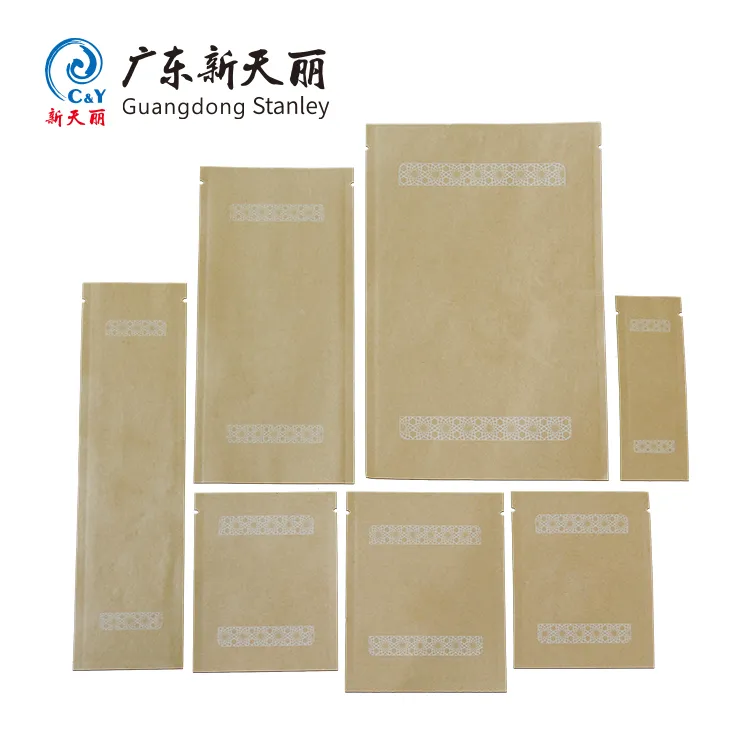

Paper

As the demand for environmentally friendly packaging increases, paper materials as a Mono-Material have gradually become a very popular choice. Paper packaging is not only renewable, but also gives products a more friendly and green appearance. Many brands are adopting paper bags, paper boxes and paper packaging bags, especially in the food and beverage industry.

Advantages:

- Paper materials can easily get recycled and biodegradable, and eco-friendly.

- It can provide naturalistic visual effects and assist with green branding.

- It is best for packaging dry goods and quick consumer goods.

Polyethylene Terephthalate

Polyester (PET) has an important position to assume in plastic packaging, especially in drinks bottles and food packaging. PET is not only highly durable but also has good clarity, so consumers can readily discern the contents of the product. With improvements in recycling technology, the PET recycling ratio is also increasing.

Advantages:

- Good transparency makes the product have a better display effect.

- High strength and good temperature resistance make it an ideal choice for long-term fresh-keeping packaging.

- It can be recycled many times and supports recycling.

Bio-based Plastics

With the emerging needs of environmental protection, bio-based plastics as a novel mono-material packaging material have attracted more and more extensive attention. They are usually made of plant-based contents, biodegradable or recyclable, and can reduce consumption of petroleum resources.

Advantages:

- Sourced from renewable resources, reducing dependence on non-renewable resources.

- Biodegradable or compostable, helping to reduce plastic waste.

- Supporting green development, in line with the trend of sustainable packaging.

Aluminum Foil

While composite materials are normally blended with aluminum foil packaging, pure aluminum is also becoming increasingly popular as a mono-material green packaging option. Aluminum foil is high in protection and can adequately separate air, moisture, and light, thereby extending the shelf life of items and especially good for food packaging.

Advantages:

- High protection, especially for products that need to be kept in a fresh state for a very long time.

- High recyclability, restricting plastic packaging environmental impact.

- Provide luxurious and high-end packaging appearance to enhance product quality.

Polylactic Acid

PLA is a bioplastic produced via fermentation of plant-derived sugar or starch, and it is widely used in biodegradable packing. It can be used for food packaging as well as general product packaging, and it complies with environmental protection regulations.

Advantages:

- Based on renewable feedstock, reducing fossil-based feedstock dependency.

- Compostable, with good biodegradability.

- Complies with increasingly stringent environmental law and consumer demand for environmentally friendly products.

Conclusion

As one of the core trends of sustainable packaging, Mono-Materials is reshaping the future of the packaging industry. Choosing the right single-material packaging can not only make the brand’s environmental image more beautiful, but also help companies acquire a competitive advantage in a world where environmental protection is receiving greater attention.

As a professional packaging pouch manufacturer, Stanley Package provides customers with high-quality, environmentally friendly single-material packaging solutions to promote the green growth of the packaging industry.

Whether it is PE, PP, Paper or PLA, the use of single materials represents the packaging industry moving in a moving towards a sustainable and eco-friendly direction, paving the way for the industry to have a green future. We will continue to provide customers with innovative and eco-friendly packaging solutions that can help them achieve their vision of sustainable development in the global market.