Choosing custom pet food packaging bags for your brand? This guide details key materials, specifications, and functions to help you create fresh, safe, and best-selling pet food packaging bags.

Why Custom Pet Food Packaging Bags Are Crucial

- Standard packaging may not meet the unique needs of your product.

- Custom pet food packaging bags precisely match product characteristics and enhance brand image.

- It directly impacts the product’s shelf life, safety, and shelf appeal.

- A good pet food packaging bag needs to balance barrier properties, durability, and cost.

Core Choices: Material Structure

The material of pet food packaging bags is the first line of defense for protecting your product. The basic structure is usually a multi-layered composite film, with each layer serving a different function.

- Base Layer (Printing Layer): Typically uses BOPP or PET film. They offer excellent printability, ensuring your brand logo is vibrant and clear.

- Barrier Layer: This is the core of the pet food packaging bag. Commonly used materials include:

- Aluminum foil (AL): Provides excellent barrier properties against oxygen, moisture, and light, suitable for high-end products or those with extremely high preservation requirements.

- Metallated film (VMPET/VMCPP): Offers good barrier properties and a metallic luster, offering good value for money.

- Transparent high-barrier film (e.g., EVOH): Suitable for products that need to display their contents while providing good oxygen barrier properties.

- Sealing layer (heat-sealing layer): In direct contact with the product, it must be safe and easy to heat-seal. Commonly used are CPP or PE. For pet food packaging bags requiring high-temperature retort resistance (e.g., wet food), special high-temperature resistant RCPP should be selected.

Key Specification Considerations

After determining the material, the specifications determine the performance and cost of the pet food packaging bag.

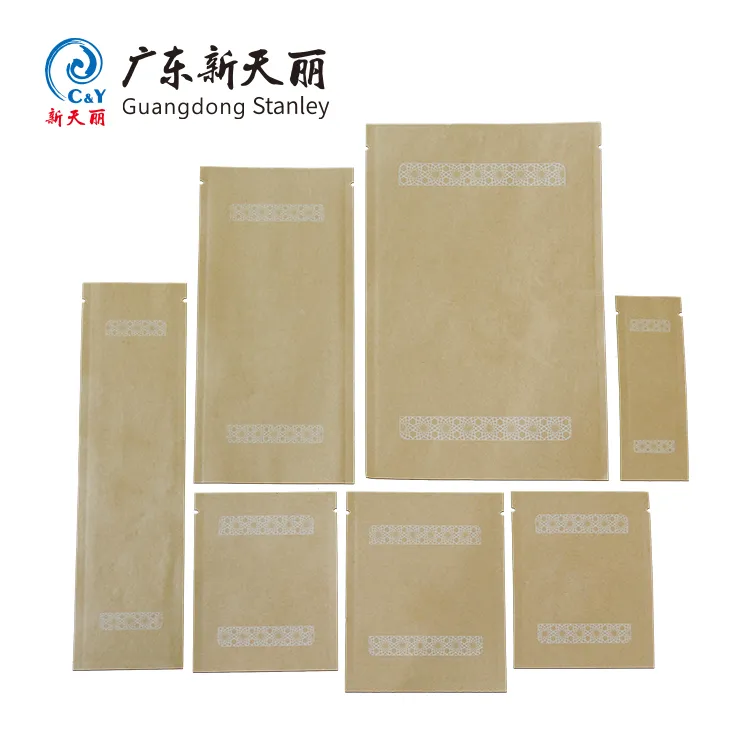

- Thickness and Size: Thickness (measured in microns) affects strength and barrier properties. Size must be precisely designed based on the net weight of the contents, allowing for adequate space.

- Bag Type Selection:

- Three-Side Seal Bags: The most versatile, suitable for most dry food and treats.

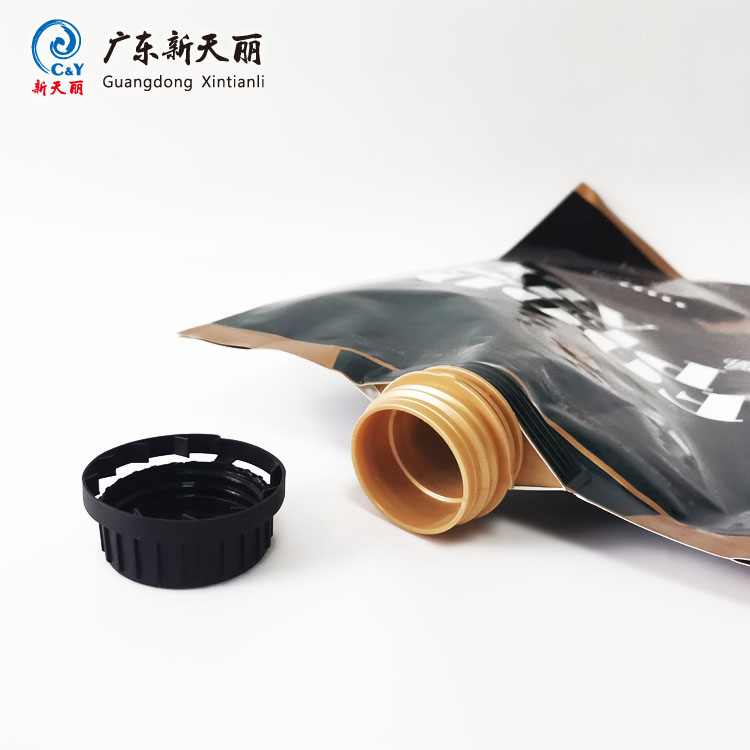

- Stand-Up Bags: Improves convenience and shelf performance; resealable, especially suitable for products requiring frequent feedings.

- Eight-Side Seal Flat Bottom Bags: Offers a larger print area and better upright posture.

- Sealing and Opening: Reliable heat seal strength is essential to prevent air leakage. Zippers, tear-off openings, and other designs greatly enhance the user experience.

Special Features and Printing Processes

Functional design can make your pet food packaging bags stand out.

- Functional Requirements: Consider whether you need antistatic, anti-slip, or enhanced puncture resistance (for bone-shaped treats).

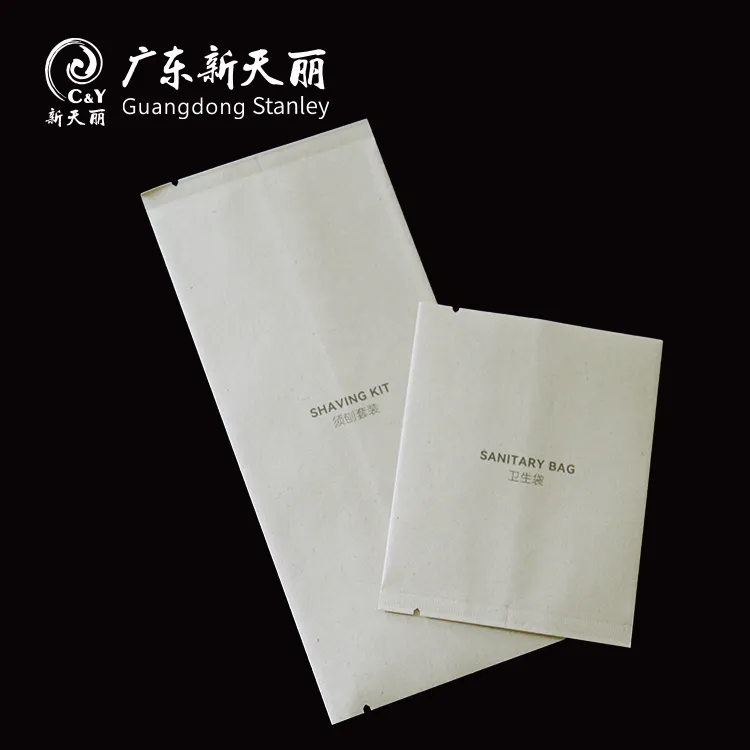

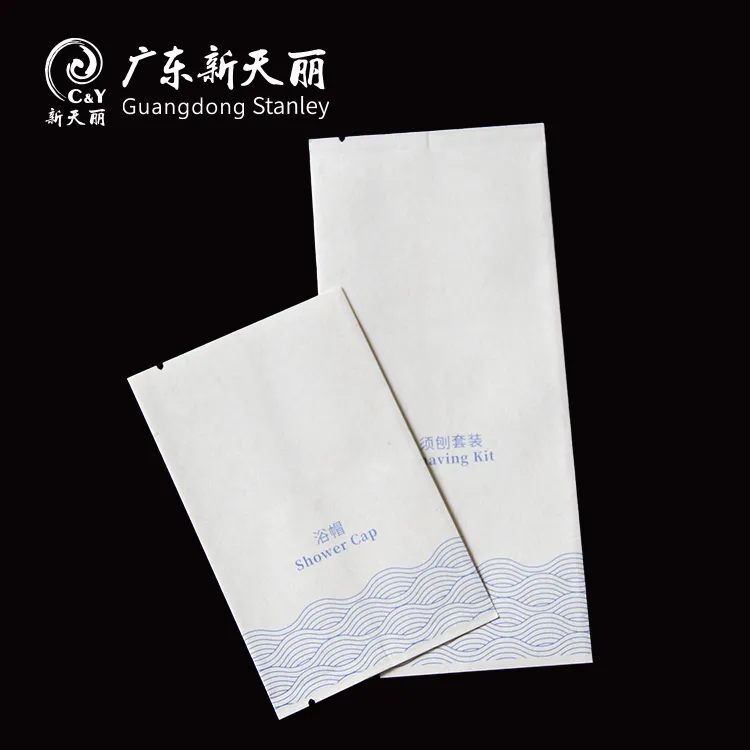

- Printing Processes: High-definition flexographic printing ensures rich and long-lasting colors. A gloss varnish or matte varnish finish can be applied to enhance texture and abrasion resistance. Lamination can also add a protective layer.

- Information Presentation: Clearly reserved space for ingredient lists, feeding instructions, QR codes, and compliance markings.

Process from Design to Production

Working with a professional pet food packaging bag manufacturer like Stanley Package typically results in a highly efficient and smooth process.

- Requirements Communication: Clearly define product type (dry/wet/treats), shelf-life requirements, budget, and design drafts.

- Sampling and Prototyping: The manufacturer provides material suggestions and creates physical samples for you to test performance (e.g., seal, drop tests).

- Production Confirmation: After sample review, mass production begins. Reputable manufacturers conduct full quality control.

- Delivery and Support: Ensuring on-time delivery of packaging bags and providing after-sales service support.

Stanley Package: Best Manufacturer for Custom Pet Food Packaging Bags

Since its founding in 1998, Stanley Package has become a leading global manufacturer of custom flexible packaging. We possess advanced production equipment and a rigorous quality management system, professionally providing high-performance, safe, and reliable customized packaging solutions for global brands. Whether it’s dry food, wet food, or pet treats, we can tailor a complete pet food packaging solution for you, from composite film to finished bags.

We have a deep understanding of market trends and regulatory requirements, and are committed to helping your products shine on the shelf through innovative packaging technologies, while ensuring the freshness and safety of your pet food.

We sincerely invite you to partner with us and make Stanley Package your trusted packaging partner. Contact us today for customized samples and a quote.