Since flexible packaging has been extensively applied in industries from food, snacks, and beverages to everyday chemicals, the printing process has been the most concerning issue for purchasers and brands. Different printing processes not only affect the package’s appearance and longevity but also directly influence the cost of production and delivery efficiency.

Stanley Package compares three common print processes: gravure, flexographic, and digital printing, to help you make informed decisions when purchasing and customizing flexible packaging.

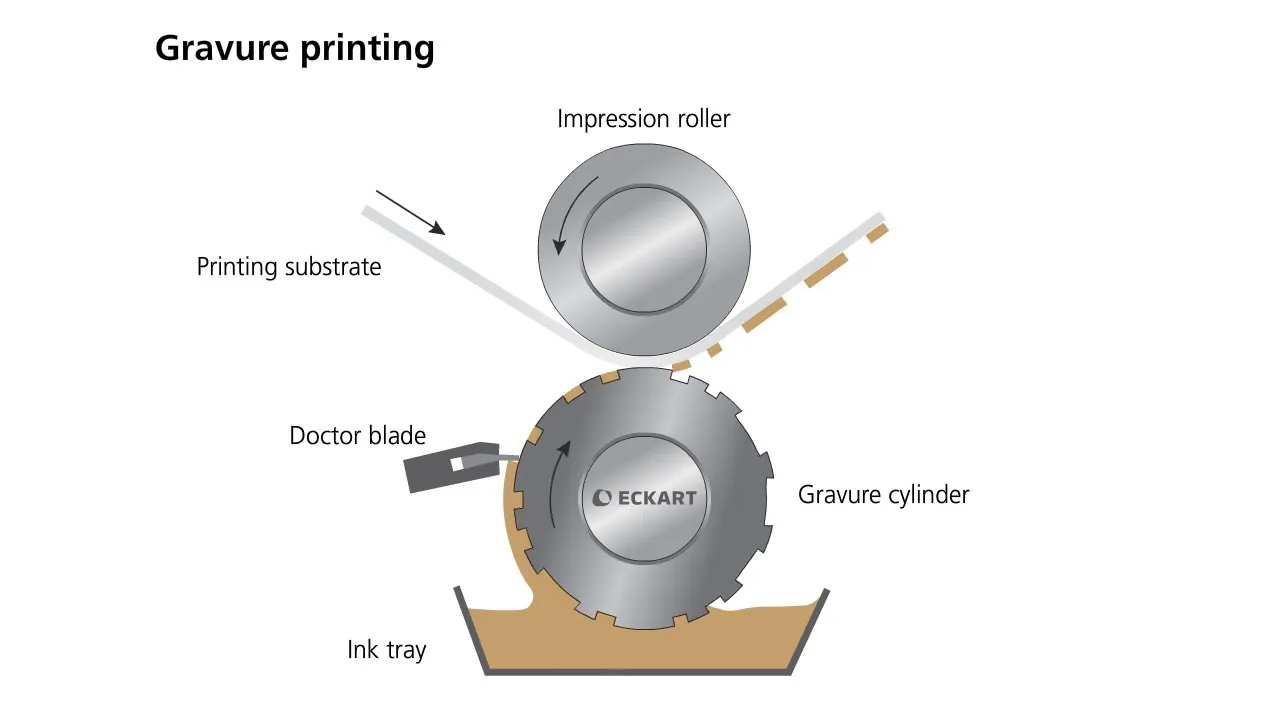

Gravure Printing

Gravure printing involves etching recessed cells with ink and then transferring the ink to the substrate. It is one of the most widely used printing methods for flexible packaging.

Advantages

- High Print Quality: High color saturation and detailed patterns, suitable for large-scale gradients and photorealistic designs.

- High-Volume Stability: Ideal for long-term, high-volume production with minimal color variation.

- Wide Compatibility: Suitable for use with a variety of films, including BOPP, PET, PE, and nylon.

Disadvantages

- High initial platemaking costs: Engraved plate rollers are expensive, making them unsuitable for small batch flexible packaging.

- Long lead time: Platemaking cycles are required.

Applications: Large-volume, high-quality food packaging, snack packaging, beverage packaging, and other products.

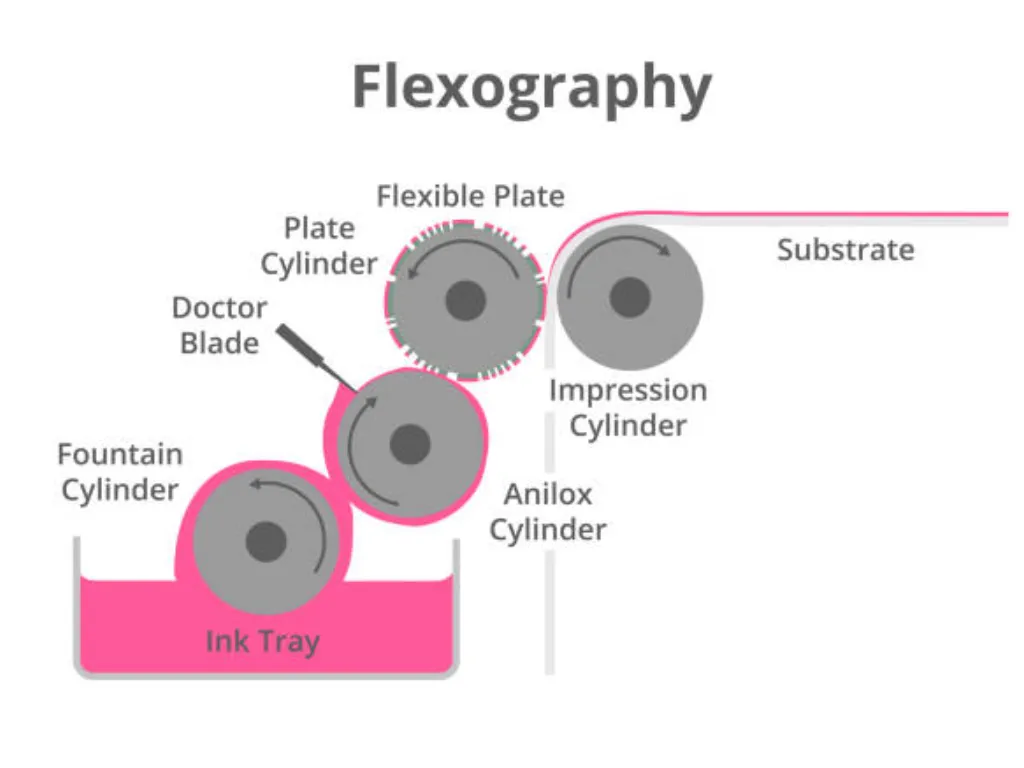

Flexographic Printing

Flexographic printing uses a flexible relief plate and quick-drying inks for transfer printing, resulting in a relatively simple process.

Advantages

- High cost-effectiveness: Platemaking costs are relatively low, making it particularly suitable for medium-volume production.

- Environmentally friendly: Water-based inks are commonly used, which better meets the needs of sustainable development.

- High efficiency: Suitable for fast delivery and flexible production.

Disadvantages

- Limited printing accuracy: Compared to gravure printing, color gradation and detail expression are slightly weaker.

- Suitable for simple patterns: Unsuitable for overly complex gradients or photorealistic patterns.

Applications: Medium-volume food, beverage, and daily chemical packaging, particularly suitable for brands emphasizing “green and environmental protection.

Digital Printing

Digital printing eliminates the need for platemaking and directly prints designs onto packaging film. It has been the fastest-growing process for flexible packaging in recent years.

Advantages

- No platemaking costs: Suitable for small batches, customized, and personalized packaging.

- Flexibility: Quickly change designs, suitable for multiple SKUs and trial products.

- Fast delivery: Shortens production cycles, meeting time-to-market demands.

Disadvantages

- High unit price: High unit cost, unsuitable for large-scale production.

- Limited material compatibility: Less effective than gravure printing on certain high-barrier films.

Applications: Small batch customization, seasonal products, promotional packaging, and e-commerce packaging.

Comparison of the Three Printing on Flexible Packaging

| Printing Method | Print Quality | Cost | Suitable Batch | Lead Time | Application Scenarios |

| Gravure | ★★★★★ | High upfront | Large batch | Longer | Mainstream snack & beverage packaging |

| Flexographic | ★★★★ | Moderate | Medium batch | Moderate | Food, personal care, eco-friendly packaging |

| Digital | ★★★ | No plate cost | Small batch | Fastest | Customized, e-commerce, promotional packaging |

How to Choose the Right Printing Process?

Branded packaging, large batches: Choose gravure printing for high image quality and optimum cost-effectiveness on long-run orders.

Medium batches, environmentally conscious: Choose flexo printing for reasonable cost and in line with green trends.

Small lots, numerous SKUs/promotional: Choose digital printing for flexibility and speed.

Stanley Package’s Printing Service Advantages

As a professional flexible packaging manufacturer, Stanley Package offers a variety of solutions, ranging from gravure and flexo to digital printing. We can recommend the most suitable process based on our customers’ volume needs, design requirements, and budget.

- Full-Process Customization: We provide a variety of film materials (such as BOPP/PET/PE/CPP) and structure combinations.

- Flexible MOQs: We can meet both long-term, stable orders from large customers and small-batch customizations.

- Efficient Delivery: We are equipped with advanced production lines and quality inspection systems to ensure color consistency and on-time delivery.

Whether you are a food, snack, e-commerce retailer, or daily chemical brand, Stanley Package can provide you with packaging and printing solutions with both quality and affordability. Contact us to start a collaborative project.