Under more stringent environmental regulations and heightened consumers’ awareness, Stanley Package, as an eco-friendly flexible packaging manufacturer, has been dedicated to integrating environmental protection into its company culture and manufacturing practices.

Under the backdrop of even more stringent environmental conditions, Stanley Package has adopted the cutting-edge Regenerative Thermal Oxidizer to treat exhaust organic waste gas produced during manufacturing comprehensively to fulfill its company environmental obligation.

What is a Regenerative Thermal Oxidizer?

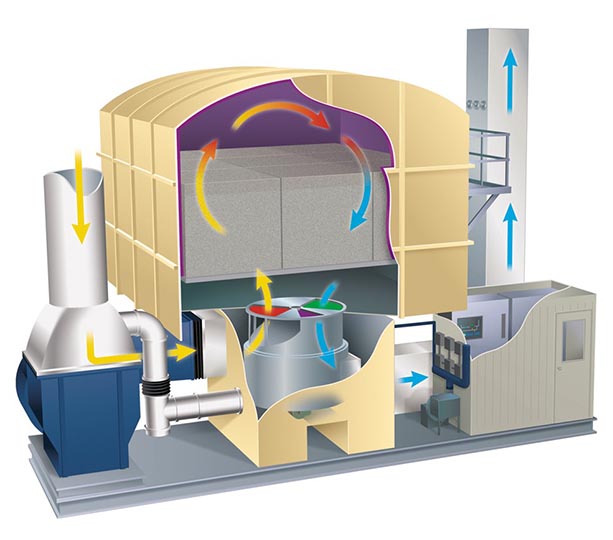

Regenerative Thermal Oxidizer is an extremely efficient, energy-saving, and eco-friendly equipment for medium- and high-concentration organic waste gas treatment. It uses high-temperature oxidation to decompose volatile organic compounds (VOCs) in organic waste gas into water and carbon dioxide, rendering the waste gas harmless.

Core Working Principle of the Regenerative Thermal Oxidizer

The RTO system operates based on thermal oxidation technology, which consists of three main stages:

Preheating Stage: The organic waste gas first enters the regenerator and is preheated to near combustion temperature by a ceramic packing bed.

Oxidative Decomposition: Preheated exhaust gas enters the combustion chamber. At temperatures ranging from 800°C to 1000°C, organic pollutants react with oxygen to produce harmless carbon dioxide and water vapor.

Heat Recovery: The heat generated during the oxidation process is absorbed and stored by the thermal storage element, which is then used to preheat incoming, lower-temperature exhaust gas, significantly reducing fuel consumption.

By periodically switching the airflow direction, the regenerative thermal oxidizer ensures effective heat recovery and continuous, stable exhaust gas treatment.

Excellent Performance of the Regenerative Thermal Oxidizer

High-Efficiency Purification Capacity

The regenerative thermal oxidizer has extremely high efficiency in purifications, usually over 95%, and correctly designed units have over 99%. This means almost all organic contaminants are converted to non-hazardous material with very little environmental impact.

Excellent Energy Savings

By utilizing very efficient heat storage materials for heat recovery, the regenerative thermal oxidizer decreases fuel consumption and operating costs significantly. The efficiency in heat recovery is more than 95%, making the system self-sustaining in operation when destroying moderate concentrations of waste gases of organics without needing external fuel.

Wide Application

The regenerative thermal oxidizer is available for the treatment of organic waste gas of any concentration and composition, and is particularly suitable for the treatment of medium- and low-concentration, large-volume waste gas. It is capable of handling huge amounts of low-concentration organic waste gas and adapting to the variation in the composition and concentration of VOCs in organic waste gas.

Intelligent Control and Safe Operation

Modern RTO systems are equipped with advanced automatic control systems for automated operation, reducing the need for manual intervention. They also feature multiple safety features, such as flameout protection, over-temperature alarms, and pressure equalization, ensuring stable and safe operation.

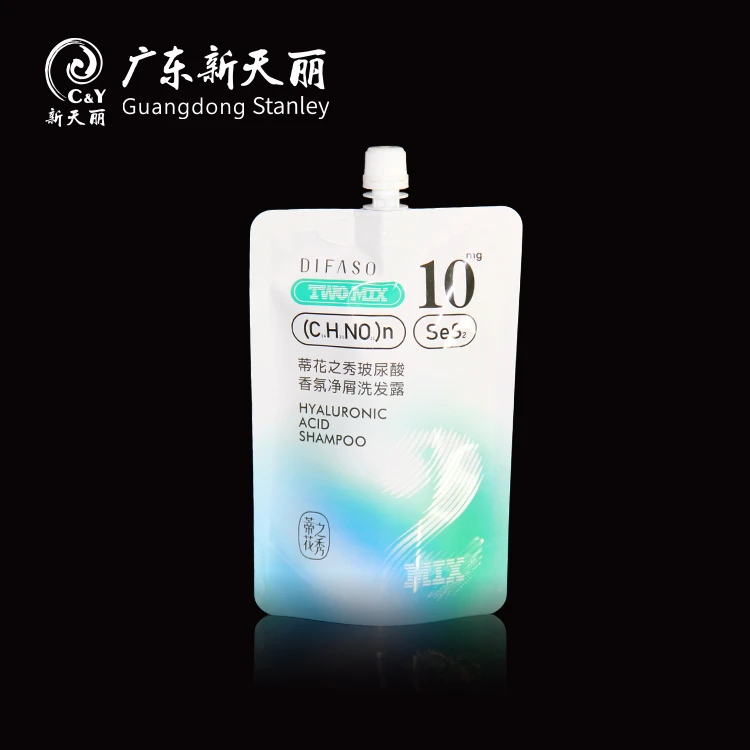

Applications of the Regenerative Thermal Oxidizer in the Flexible Packaging Industry

In the packaging production process, particularly in printing, laminating, and coating processes, various inks, diluents, and adhesives are used, which often contain volatile organic compounds.

The regenerative thermal oxidizer effectively treats the organic waste gas generated in these processes, ensuring that final emissions meet or even exceed environmental standards. The RTO system demonstrates excellent treatment effectiveness for organic waste gases such as ethyl acetate, butanone, n-butyl ester, cyclohexanone, and isopropyl alcohol generated during the production of aluminum foil packaging.

Stanley Package’s Environmental Commitment

Since its founding in 1998, Stanley Package has prioritized environmental protection as a core element of its business development. Our investment in the RTO system demonstrates our unwavering commitment to environmental protection:

Emission Compliance Guarantee

Through the regenerative thermal oxidizer, we ensure that waste gases generated during our production processes fully meet or exceed national and local environmental emission standards, contributing to the protection of the atmospheric environment.

Efficient Resource Utilization

The heat recovery feature of the regenerative thermal oxidizer enables us to significantly reduce energy consumption, reduce carbon emissions, and improve resource efficiency.

Comprehensive Environmental Protection Measures

In addition to waste gas treatment, we implement a comprehensive range of environmental protection measures, including wastewater treatment and waste management, to ensure that the entire production process meets environmental requirements.

Continuous Improvement and Innovation

We will continue to monitor developments in environmentally friendly technologies, continuously improving our production processes and pollution control techniques to set an example for the industry’s green transformation.

Social Benefits of Regenerative Thermal Oxidizer

Investing in an RTO system not only ensures compliance for businesses but also generates significant social benefits:

Improving regional environmental quality: Reducing air pollutant emissions in surrounding areas and improving the quality of life for residents.

Demonstration for the industry: Setting a green production benchmark for the packaging industry and leading the industry’s transition to a sustainable development model.

Contributing to carbon neutrality goals: Contributing to global climate goals by reducing carbon emissions.

Looking to the Future

With the continued strengthening of environmental policies and technological advancements, Stanley Package will continue to increase its investment in environmental protection and continuously improve its exhaust gas treatment system.

We believe that economic development and environmental protection can go hand in hand. By adopting advanced treatment technologies like Regenerative Thermal Oxidizer, we can maintain our competitiveness while fulfilling our corporate environmental responsibilities.

By choosing Stanley Package, you not only receive high-quality flexible packaging solutions, but also support a partner committed to environmental protection. We look forward to working with you to create a greener and more sustainable future.