In the flexible packaging industry, a gusset is central to a bag’s capacity, stability, and shelf appeal. Whether you are using a stand-up pouch, a side-seal bag, or roll-stock packaging, a well-designed gusset allows products to not only function but look better.

For manufacturers and brand owners, knowing what a gusset is is key in obtaining a proper balance of design efficiency as well as production quality.

What Is a Gusset? Definition and Types

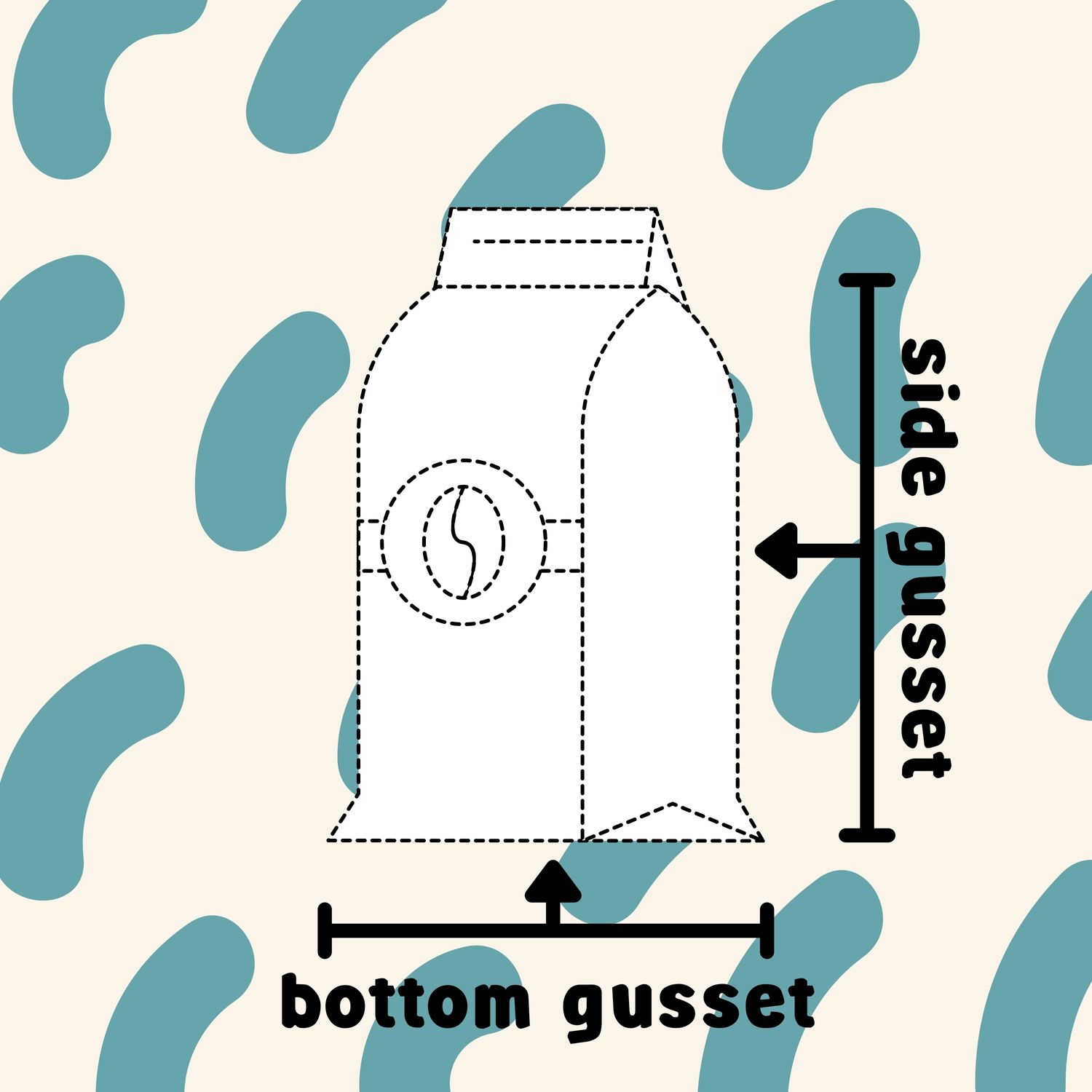

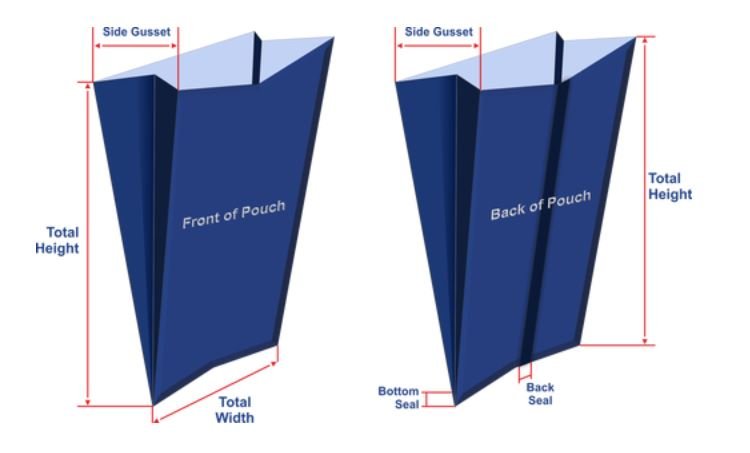

A gusset is the area that is folded along the sides or bottom of the pouch. When the package is opened, the gusset expands, thereby increasing internal volume and allowing for a three-dimensional shape overall.

Various Gusset Types

- Side Gusset – Folds on each side create additional storage.

- Bottom Gusset – A folded area at the bottom of the pouch that enables the bag to stand on its own (often called a stand-up pouch).

- Three-Side Gusset – A combination of a side gusset and bottom gusset to create maximum flexibility and strength.

Main Functions

- Increase Capacity – Adds internal volume of 30-50%.

- Improve Stability – Bottom gussets provide stability allowing the bag to stand upright.

- Increase Product Display Quality – 3D structure offers product prominence.

- Enhanced User Experience – More usable and a luxury appearance.

Key Design Considerations for Gusset Structure

1. Gusset Width Ratio

The width of gussets has a direct impact on the space available within the pouches and on the stability of the pouch.

- A side gusset should generally be 10%–25% of the total width of the bag.

- A bottom gusset should generally be 15%–30% of the total height of the bag.

For example, a pouch of dimensions 14 cm × 22 cm with a 5 cm side gusset will expand the functional pouch capacity by approximately 40%. If the gusset is too wide, the pouch may deform, whereas too small of a gusset limits the space inside the pouch.

2. Material Thickness and Flexibility

Overly thick films can crack during folding, while overly thin films may lose strength.

Common structures include PA/PE and BOPP/PA/PE, which offer good flexibility for gusset forming.

For multilayer films, crease-resistance testing is essential to prevent cracking during long-term use.

3. Printing and Aesthetic Harmony

Since gusset folds are complex, avoid placing logos or key visuals along fold lines.

Use gradient backgrounds or solid color blocks for consistency.

For instance, side gussets can feature a matching gradient tone to blend with the main artwork.

4. Heat Sealing and Production Compatibility

Because film layers overlap at gusset folds, sealing parameters must be carefully adjusted:

- Avoid placing sealing lines directly over folds.

- Control sealing temperature and pressure precisely.

- Ensure your gusset folding device matches the desired width.

For example, a client once experienced cracking on stand-up pouch bottoms due to improper sealing.

After Stanley Package optimized the sealing position, their yield rate improved to 99%.

Applications of Gusset in Different Packaging Types

| Packaging Type | Gusset Type | Advantages | Key Considerations |

|---|---|---|---|

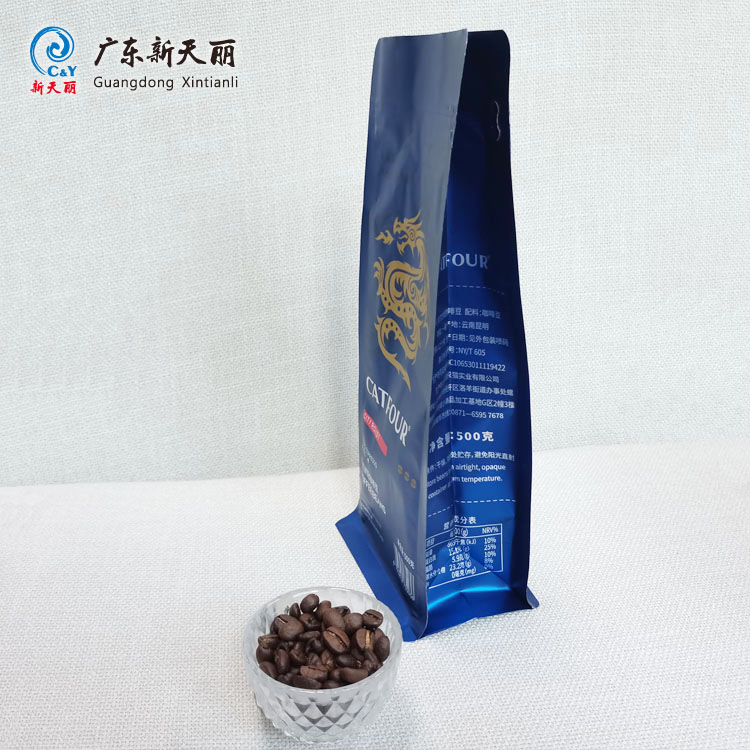

| Stand-up Pouch | Bottom Gusset | Stands upright, strong visual impact | Requires strong compression resistance |

| Three-Side-Seal Bag | Side Gusset | Adds volume while keeping flat shape | Cannot stand independently |

| Roll Stock Film | Pre-set Gusset | Increases efficiency in bag-making | Requires precise tension control |

Practical Examples

- Coffee Bags – 6 cm bottom gusset ensures stability and extra capacity.

- Pet Food Bags – 8 cm side gusset provides strength and load resistance.

Each product type should select the gusset design based on weight, shape, and display needs.

Practical Tips for Production

- Use Smooth Fold Radii – Reduces stress concentration and cracking.

- Offset Sealing Lines – Avoid overlapping thick folded layers.

- Control Film Tension – Keeps gusset folds centered and symmetrical.

- Conduct Sample Tests – Drop, aging, and filling tests ensure gusset durability.

These small details significantly impact product stability and appearance.

In one high-barrier roll film project, Stanley Package optimized gusset folding, cutting the defect rate by 70% and boosting efficiency.

Conclusion

A gusset is one of the most essential structural elements in flexible packaging. When properly designed, it not only increases capacity and enhances appearance but also improves stacking and transportation performance.

To maximize its benefits, designers should consider width ratio, material flexibility, sealing structure, and machine compatibility — and always validate with real-world testing.

A well-engineered gusset can elevate your packaging’s professional appeal and market competitiveness.

About Stanley Package

Founded in 1998, Stanley Package is a global Custom Flexible Packaging Manufacturer specializing in high-performance packaging pouches and roll-stock films. With a 15,000 m² production facility and advanced RTO environmental system, we deliver complete gusset design solutions — from concept and lamination to bag making. Our innovation, precision, and efficiency have earned us long-term trust from global brands seeking reliable packaging partners.