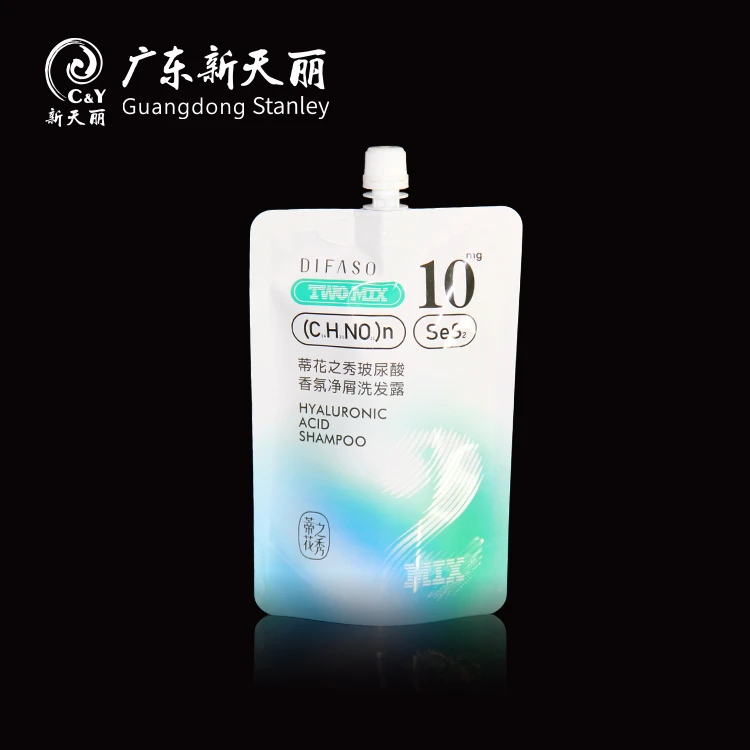

The viscosity differences of sauce products determine the success or failure of packaging. This article will delve into why nozzle diameter is crucial for the efficient filling of high-viscosity products and provide industry-standard viscosity matching data to help brands improve production efficiency through customized spouted stand up pouches.

High-Viscosity Filling: Why is Nozzle Diameter Crucial for Sauce Packaging?

In the condiments and sauces industry, choosing the right packaging format is only the first step. The real technical challenges often lie in the details—especially the nozzle/spout specifications of the spouted stand up pouches. The nozzle diameter not only determines the consumer experience but also directly impacts the OEE (Overall Equipment Effectiveness) of the factory’s filling line.

1. Viscosity Level and Recommended Nozzle Diameter Reference Table

When designing a spouted stand up pouches, the inner diameter (ID) of the nozzle must be precisely matched to the apparent viscosity of the product. The following are industry standard references based on Stanley Package’s years of manufacturing experience:

| Sauce Category | Typical Viscosity (cP) | Physical Characteristics Description | Recommended Nozzle Inner Diameter (ID) |

|---|---|---|---|

| Low Viscosity Condiments | 1 – 2,000 | Similar to water or thin oil (e.g., vinaigrette, light syrup) | 8.5mm – 10mm |

| Medium Viscosity Fluids | 2,000 – 10,000 | Flowable but relatively slow (e.g., dish soap, maple syrup) | 10mm – 13mm |

| High Viscosity Pastes | 10,000 – 50,000 | Typical non-Newtonian fluid (e.g., ketchup, mayonnaise) | 13mm – 16mm |

| Ultra-High Viscosity/Containing Particles | 50,000+ | Extremely difficult to flow and contains solid particles (e.g., chili sauce, peanut butter) | 16mm – 22mm+ |

2. The “3:1 Principle” for Particle Throughput

To select horizontally facing spouted stand up pouches containing added ingredients such as crushed black pepper, chili seeds, or fruit pulp, there is a strict adherence to the physical logic of the nozzle inner diameter being three times greater than that of the largest particle in the sauce.

- Technical Case Study: The use of a 3mm chili flutter/flaking could create a blockage at the filling head with an 8.5mm nozzle, while a 13mm nozzle would minimise maintenance downtime on production lines by 85%.

3. The Impact of Back Pressure on Loss and Accuracy

If the spout of the spouted stand up pouches is too small, the filling pump must apply extra pressure to push the product into the bag, which creates a chain reaction:

- Air Bubble Intrusion: High-pressure filling easily causes cavitation, introducing tiny air bubbles into the sauce, accelerating oxidation and shortening shelf life.

- Filling Deviation: When high-viscosity liquids pass through a narrow opening, flow resistance causes deviations in the filling volume per bag, significantly increasing raw material loss costs.

4. Extrusion Stress and End-of-Use Emptying Rate

The core of consumer evaluation of spouted stand up pouches lies in the “emptying rate.”

- Narrow Opening: Applying more than 15N of pressure is required to squeeze out residual sauce, which can easily cause excessive stress at the base of the bag, leading to leakage at the heat-sealed area.

- Optimized Opening: A reasonable opening allows air to quickly flow back after squeezing, reducing deformation of the bag due to vacuum and increasing the product emptying rate to over 98%.

How Does the Material Structure Support High-Strength Extrusion?

Aside from an external tap, the outside structure of the composite materials that compose the spouted stand up pouches must also endure the stress created from high viscosity extrusion. It is usually recommended that multi-layer material combinations with very high barrier properties and good extrusion resistance (e.g., PET/NY/PE or a high-barrier composite) be used to maintain an attractive package that is leak-free after multiple squeezes.

Stanley Package: Your Trusted Flexible Packaging Partner

Selecting an appropriate packing supplier is essential for brand growth. Stanley Package has been a worldwide Custom Flexible Packaging Manufacturer since 1998 and has worked in this field for more than twenty years, earning a reputation for superior production equipment and an impressive quality assurance program.

Our production base covers 15,000 square metres, where we manufacture different types of packaging pouches (e.g., shaped & spouted) and roll stock packaging film. In addition to focusing on the quality of our products, we value our commitment to sustainable development. We have implemented efficient and eco-friendly RTO systems to regulate emissions and ensure that all spouted stand up pouches produced are consistent with environmental standards.

Whether you are a startup brand or a global enterprise, Stanley Package can provide you with a one-stop solution, from specification selection and material development to large-scale production.

Ready to optimize your sauce packaging?

[Contact our packaging experts] to get customized spouted stand-up pouch technical solutions and free samples.